- Product Details

- {{item.text}}

Quick Details

-

Thermal Conductivity:

-

0.17-0.28

-

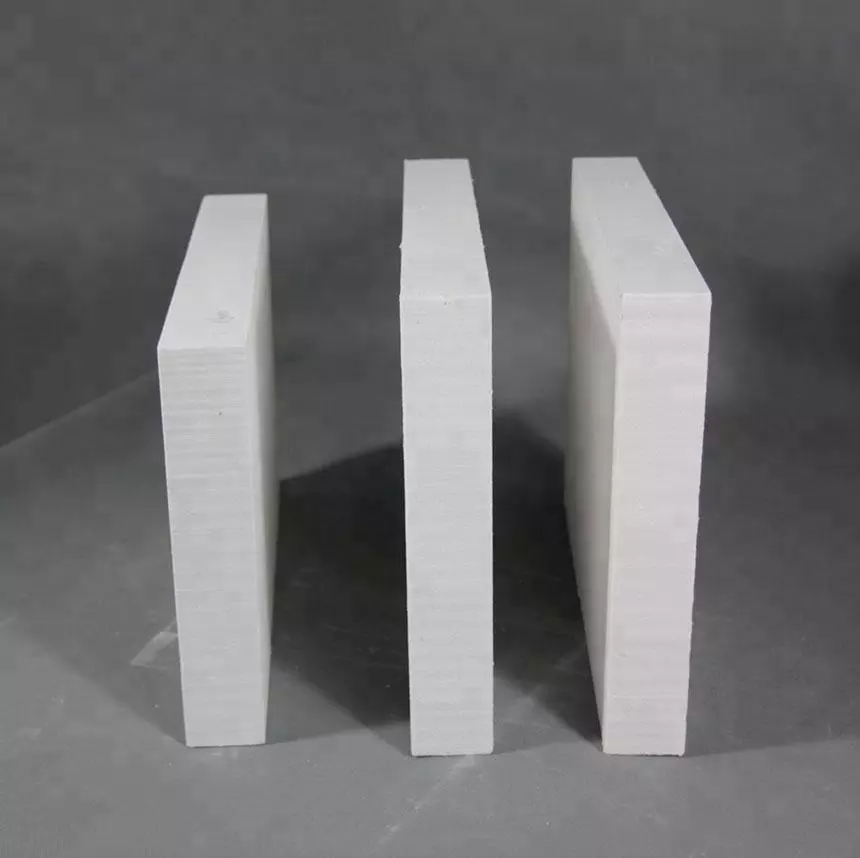

Thickness:

-

20-100mm

-

Width:

-

600mm

-

Length:

-

1000mm

-

Working Temperature:

-

1700

-

Place of Origin:

-

Henan, China

-

Model Number:

-

SYN-1800

-

Brand Name:

-

SYN

-

Product name:

-

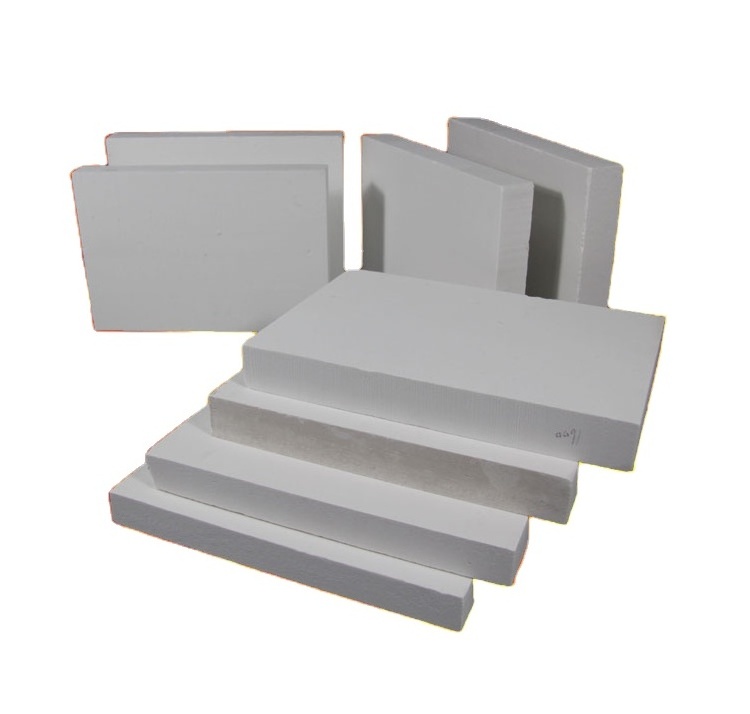

1800C Refractory Ceramic Fiber Board

-

Raw material:

-

Silica+Alumina

-

Certificate:

-

ROHS

-

Shape:

-

Clinet's

-

MAX Temp:

-

1800

-

Application of ceramic fiber board:

-

Refractory

-

Package:

-

Wooden Box

-

Bulk density:

-

400-500kg/m3

-

Delivery Time:

-

7-20days

-

Color:

-

White

Quick Details

-

Chemical Composition:

-

Al2O3+SiO2

-

Ultimate Strength (≥ MPa):

-

0.6

-

Fiber Diameter:

-

3-5um

-

Thermal Conductivity:

-

0.17-0.28

-

Thickness:

-

20-100mm

-

Width:

-

600mm

-

Length:

-

1000mm

-

Working Temperature:

-

1700

-

Place of Origin:

-

Henan, China

-

Model Number:

-

SYN-1800

-

Brand Name:

-

SYN

-

Product name:

-

1800C Refractory Ceramic Fiber Board

-

Raw material:

-

Silica+Alumina

-

Certificate:

-

ROHS

-

Shape:

-

Clinet's

-

MAX Temp:

-

1800

-

Application of ceramic fiber board:

-

Refractory

-

Package:

-

Wooden Box

-

Bulk density:

-

400-500kg/m3

-

Delivery Time:

-

7-20days

-

Color:

-

White

Product Description

Factory Price 1801c Aluminosilicate Refractory Ceramic Fiber Board for Heat Resistant

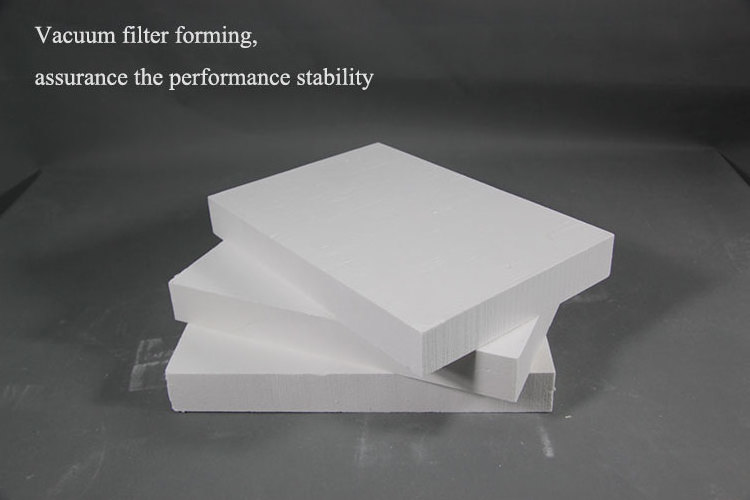

Ceramic fiber board is a kind of high-temperature-resistant refractory material board. It is made of ceramic fiber and adhesive through the vacuum suction filtration molding process. It has the characteristics of low thermal conductivity, high-temperature stability, uniform density, thermal shock resistance, and chemical corrosion resistance

Specification

|

Type

|

|

SYN-1260

|

SYN-1400

|

SYN-1500

|

SYN-1600

|

SYN-1700

|

SYN-1800

|

SYN-1900

|

|

|

Classification Temperature(℃)

|

|

1260

|

1400

|

1500

|

1600

|

1700

|

1800

|

1900

|

|

|

Working Temperature(℃)

|

|

1000

|

1200

|

1350

|

1500

|

1600

|

1700

|

1750

|

|

|

Color

|

|

Pure White

|

Pure White

|

Pure White

|

Pure White

|

Pure White

|

Pure White

|

Pure White

|

|

|

Density(kg/m3)

|

|

250-400

|

250-400

|

3

00-400

|

400

|

400

|

400-500

|

700

|

|

|

Thermal Conductivity(w/mk)

|

0.09400℃

|

0.09

|

-

|

-

|

-

|

-

|

-

|

-

|

|

|

|

600℃

|

0.12

|

0.12

|

0.12

|

-

|

-

|

-

|

-

|

|

|

|

800℃

|

0.16

|

0.15

|

0.16

|

0.14

|

0.15

|

0.17

|

0.2

|

|

|

|

1000℃

|

-

|

0.23

|

0.23

|

0.17

|

0.19

|

0.24

|

0.3

|

|

|

|

1200℃

|

-

|

-

|

0.25

|

0.23

|

0.27

|

0.28

|

0.33

|

|

|

Chemical Comsosition(%)

|

Al2O3

|

43

|

45

|

60

|

64

|

75

|

80

|

87

|

|

|

|

Al2O3+SiO2

|

98

|

98

|

98

|

98

|

99

|

99.5

|

99.5

|

|

|

|

BaO

|

<0.2

|

<0.2

|

<0.2

|

<0.1

|

<0.05

|

<0.05

|

<0.05

|

|

|

|

Fe2O3

|

<1.2

|

<1.2

|

<0.5

|

<0.5

|

<0.2

|

<0.1

|

<0.1

|

|

|

Shrinkage(%)

|

|

1100℃*24h-3

|

1200℃*24h-2.5

|

1400℃*24h-2

|

1500℃*24h-1

|

1600℃*24h-0.5

|

1700℃*24h-0.40

|

1750℃*24h+0.1~-0.4

|

|

|

Combustion Loss(%)

|

|

≤5%

|

≤5%

|

≤4.5%

|

≤4.5%

|

≤5%

|

≤3.5%

|

≤4%

|

|

|

Compressive Strength(MPa)

|

|

0.3

|

0.4

|

0.5

|

0.5

|

0.6

|

0.6

|

0.8

|

|

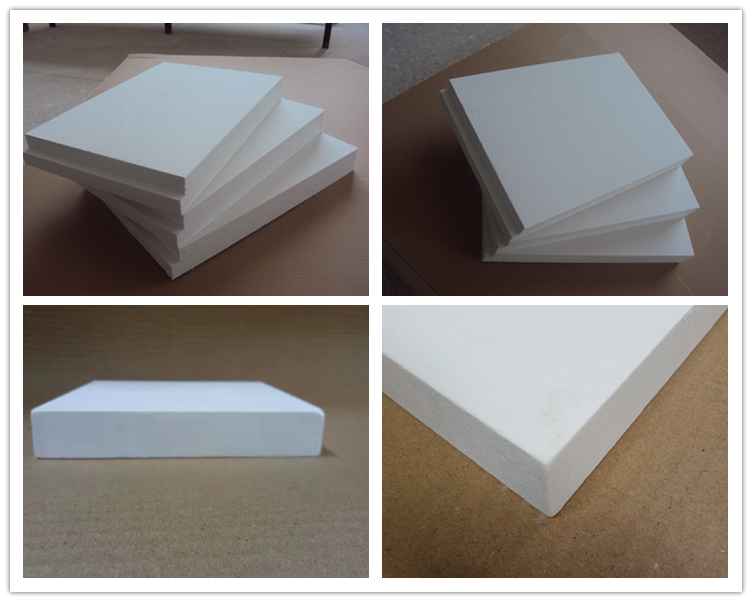

Standard Size

:1200*1000*20-100mm/1000*600*20-100mm

Other shapes and sizes can be made according to your requirements!

NOTE : Above working temperature is under the long-term oxidizing atmosphere, while a special working environment is needed, please make technical communication first.

Other shapes and sizes can be made according to your requirements!

NOTE : Above working temperature is under the long-term oxidizing atmosphere, while a special working environment is needed, please make technical communication first.

Hot Searches