- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v,380v,440v

-

Dimension(L*W*H):

-

Based

-

Weight:

-

3600kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Online support, Video technical support, Field installation, commissioning and training, Field maintenance and repair service

-

Warranty period:

-

1 year

-

After sale service:

-

Spare parts supply

-

Product Name:

-

Industrial Vibrating Sieve Supplier

-

Certification:

-

CE, ISO

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UNIQUE

-

Voltage:

-

220v,380v,440v

-

Dimension(L*W*H):

-

Based

-

Weight:

-

3600kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Online support, Video technical support, Field installation, commissioning and training, Field maintenance and repair service

-

Warranty period:

-

1 year

-

After sale service:

-

Spare parts supply

-

Product Name:

-

Industrial Vibrating Sieve Supplier

-

Certification:

-

CE, ISO

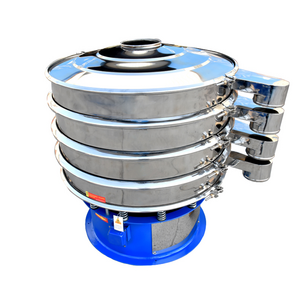

UNIQUE Industrial Vibrator Mechanical sifter

Introduction of Vibrator Mechanical sifter

The Vibrator Mechanical sifter Equipment, also called circular vibrating screen moves on a circular motion. It is a multi-layer and high efficiency vibrating screen. Advantages are: stable structure, strong exciting force, high efficiency, little noise pollution, handy maintenance and safety; circular vibrating screen has been widely used in mine, construction, transportation, energy and chemical industries.

Features of Vibrator Mechanical sifter

1. Stable performance under violent vibrating, for the fixing bolts are widely applied to connecting the main frame and the screen tightly.

2. Large handling capacity, which can reach 810 ton per hour.

3. Long flow line and various screening specifications.

4. Small amplitude, high frequency, large-inclination structure, high efficiency, large capacity, long service life, low power consumption and noise.

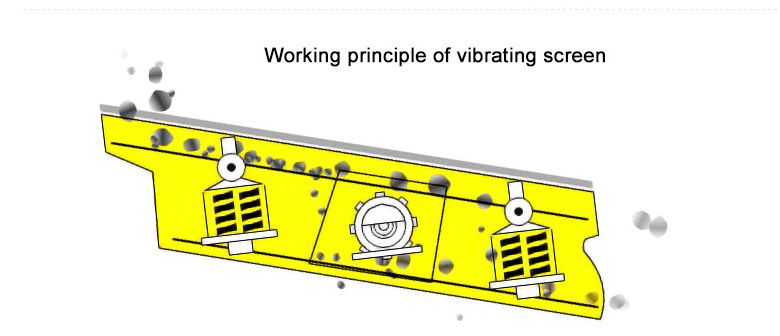

Working Principle of Vibrator Mechanical sifter

The vibrating sifter for sand is to drive vibrator through V-belt under the power of ordinary motor, so that the screen body along the vibrating power direction to make a cyclical reciprocating, the material in the screen surface to make round movement, so as to make the materials sieved.

Main Specification of Vibrator Mechanical sifter

| Model |

Sieve Layer |

Max. Feeding Size(mm) |

Capacity (m³/h) |

Motor Power (kw) |

Weight (kg) |

| 2YK1225 | 2 | 400 | 8-60 | 5.5 | 2500 |

| 3YK1225 | 3 | 400 | 10-70 | 5.5 | 2850 |

| 2YK1230 | 2 | 400 | 12-78 | 7.5 | 3000 |

| 3YK1230 | 3 | 400 | 13-80 | 7.5 | 3600 |

| 2YK1237 | 2 | 400 | 15-86 | 7.5 | 3600 |

| 3YK1237 | 3 | 400 | 16-90 | 7.5 | 4200 |

| 2YK1535 | 2 | 400 | 20-125 | 11 | 4890 |

| 3YK1535 | 3 | 400 | 21-125 | 11 | 5700 |

| 2YK1545 | 2 | 400 | 22-150 | 15 | 5330 |

| 3YK1545 | 3 | 400 | 22-150 | 15 | 5800 |

| 2YK1548 | 2 | 400 | 22.5-162 | 15 | 5980 |

| 3YK1548 | 3 | 400 | 22.5-162 | 15 | 6600 |

| 2YK1848 | 2 | 400 | 25-206 | 15 | 7080 |

| 3YK1848 | 3 | 400 | 32-276 | 18.5 | 7600 |

| 2YK1854 | 2 | 400 | 32-312 | 18.5 | 8150 |

| 3YK1854 | 3 | 400 | 32-312 | 22 | 8840 |

| 2YK2160 | 2 | 400 | 50-475 | 30 | 9780 |

| 3YK2160 | 3 | 400 | 50-475 | 30 | 10800 |

| 2YK2460 | 2 | 400 | 65-550 | 37 | 13600 |

| 3YK2460 | 3 | 400 | 70-620 | 37 | 15600 |

Packaging

:standard Container Packs or in Bulk.The electrical motor or spare parts will be packed by wooden case or steel frame.Unique offers various ways of package, fumigation-free wooden cases, steel plate cases, or as the clients' request. Most of the time, the equipment will be loaded to the containers in the factory. Unique workers make sure all equipment are steady and fixed before close the door of the container, there will be no damage during transporation and shipment.

Shipping

:we deliver the cargo to China's main sea ports,such as Qingdao,Tianjin,Shanghai etc.And then the container will be transported to your country by sea.

After-sales service support

1.more than 12 months' warranty period

2.Erection and Commissioning

3.Operator Training

4.Spare Parts Supply

Normally,Equipment spares will be offered with manufacturing cost in at least 10 years since the order is placed. To establish long term cooperation, we will regularly call and email our clients, to check the equipment working condition, offer suggestions for maintenance, and if necessary we will pay a visit to clients to solve the problems caused during equipment working.