- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Loading and discharging LPG

-

Color:

-

Customer's Requrements

-

Motor power:

-

5.5kw

-

Power:

-

380v/50hz/3phase

-

Pressure:

-

1.6 Mpa

-

Capacity:

-

1.0m3/min

-

MOQ:

-

1set

Quick Details

-

Place of Origin:

-

Hubei, China

-

Product name:

-

lpg compressor for lpg fillilng station

-

Cooling method:

-

Air Cooling

-

Application:

-

Loading and discharging LPG

-

Color:

-

Customer's Requrements

-

Motor power:

-

5.5kw

-

Power:

-

380v/50hz/3phase

-

Pressure:

-

1.6 Mpa

-

Capacity:

-

1.0m3/min

-

MOQ:

-

1set

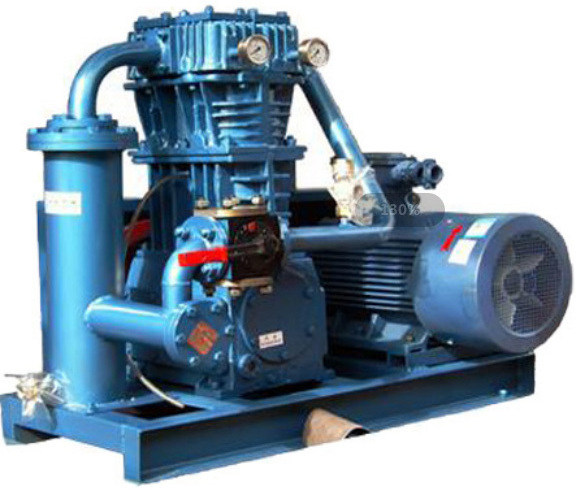

China brand LPG CNG liquefied petroleum gas compressor biogas compressor gas booster compressor

Techinical parameter for lpg compressor ZW-1.6/10-16:

|

No. |

Items |

Specification |

|

|

1 |

Model |

ZW-1.6/10-16 |

|

|

2 |

Medium |

LPG |

|

|

3 |

Stucture |

Vertical/Wind Cool/ TWO Cylinder |

|

|

4 |

Stage |

1 |

|

|

5 |

Capacity ( m3/min) |

1.6 |

|

|

6 |

Inlet Pressure (Mpa) |

1 |

|

|

7 |

Discharge Pressure (Mpa) |

1.5 |

|

|

8 |

Inlet Temp ( ℃ ) |

≤40 |

|

|

9 |

Outlet Temp ( ℃ ) |

≤110 |

|

|

10 |

Speed(r/min) |

730 |

|

|

11 |

EX Motor |

YB2-180L-4 d Ⅱ BT 4 |

|

|

380V 50HZ,22KW |

|||

|

12 |

Cooling Type |

Wind |

|

|

13 |

Lubricant |

Shaft, Connecting Rod, Crosshead |

Splash Lubrication |

|

Cylinder, Padding |

Non Oil Lubrication |

||

|

14 |

Driving Type |

Belt-Driven |

|

|

15 |

Installation |

With basement |

|

|

16 |

Noise (dB (A)) |

85 |

|

|

17 |

Intension of Vibration |

28 |

|

|

18 |

Dimension L X W X H ( mm) |

1220×780×980 |

|

|

19 |

Gross Weight (kg ) |

720 |

|

|

20 |

Auto Control |

/ |

|

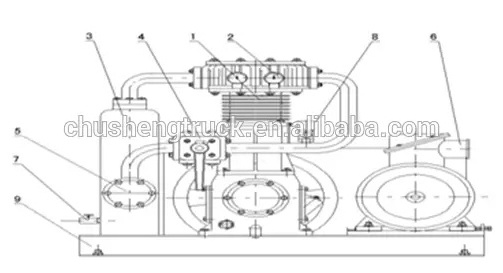

II. Major Structure and working principle of the lpg compressor:

The overall structure of compressor unit is shown in Figure 1. It is combined by 1-compressor 2. — Instruments 3. — Liquid-vapor separator 4. — Two four-way valve 5 — Air intake filter 6 — Explosion-proof motor 7 — Drain valve II 8 — Safety valve 9 — Composed by fundation and shield.

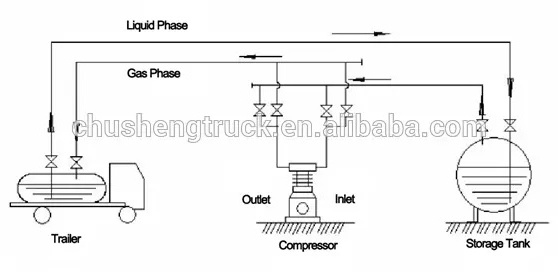

III. Process flow of liquefied petroleum gas loading and unloading:

1. Liquid delivery

Initially, open the liquid tube between the tanker and the tank,

The liquid in the tank automatically flows into the tank. To reach a balance and stop flowing. Start the compressor, adjust the four-way valve, extract gas and be pressed through the compressor then discharged into the tanker. At this point the tanker pressure increases, the tank pressure drops, tanker liquid flows into the tank.

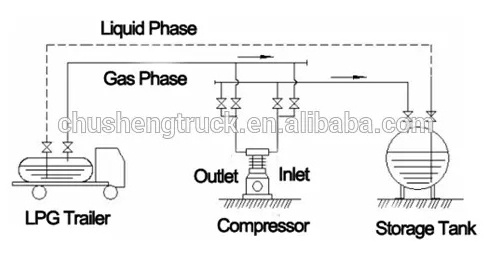

2. Remaining gas recovery

The residual gas recovery process is opposite to the liquid delivery. After the liquid is delivered, the four-way valve should be reversed and the pipe (dotted line) is closed. At this point, the residual gas in the tank is sucked by the compressor, pressurized and discharged to the tank until the remaining gas pressure drops to no recovery value.

Wooden Box