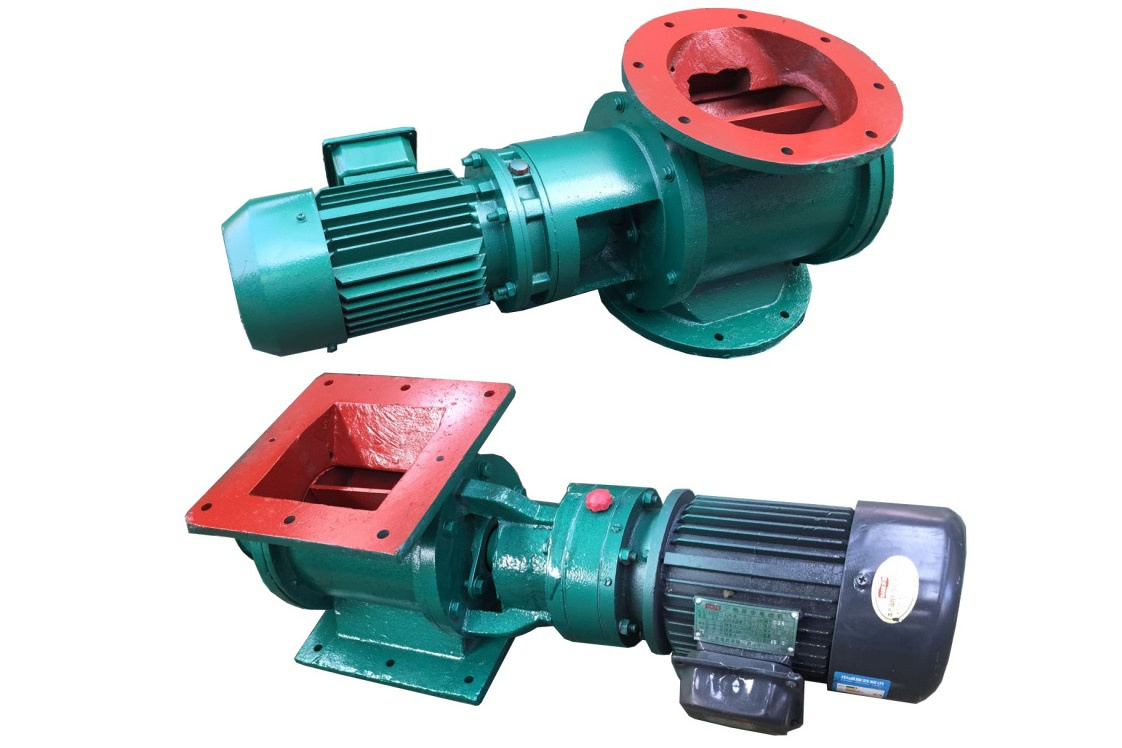

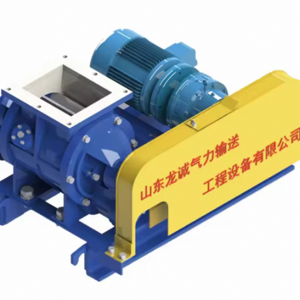

Working pressure: from - 0.5 bar up to 0.8 bar

Capacity: 5 - 10 - 15 - 20 - 38 - 78 litres per revolution (0.17 - 0.35 - 0.52- 0.7 - 1.23 - 2.82 cu ft/rev

Working temperature

:

from -40 °C up to 220°C

Application:

Silo Vent, Dust Filters, “Big Bag” Filling Stations, Flexible Spiral Conveyors, Screw Conveyors

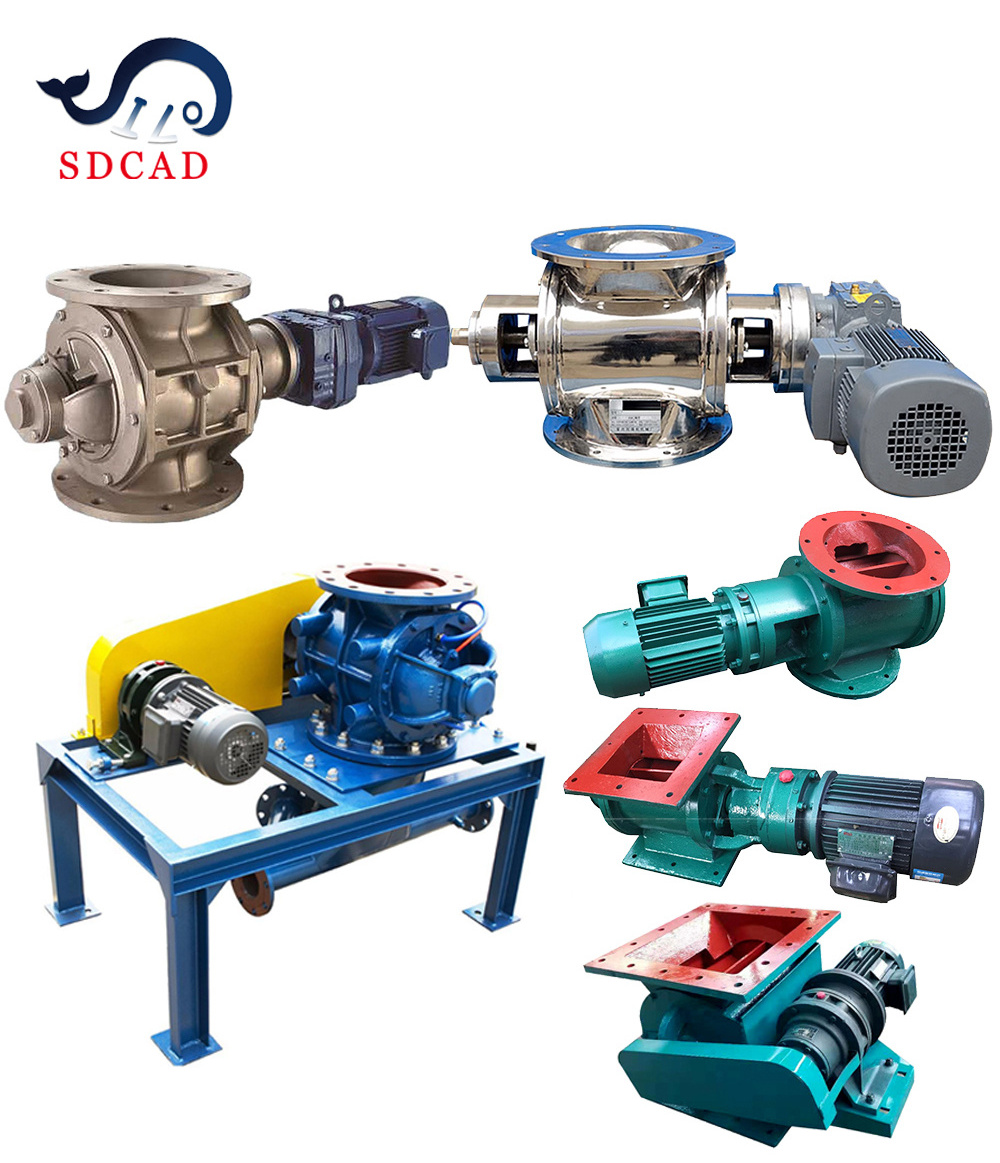

Customized Solution is the Core concepts of SDCAD