- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

319

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Ruding

-

Product Name:

-

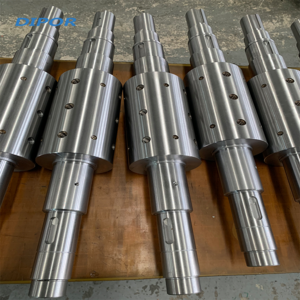

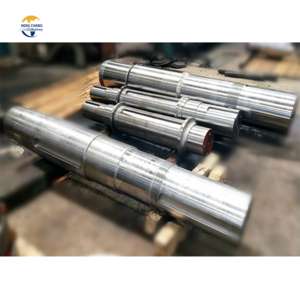

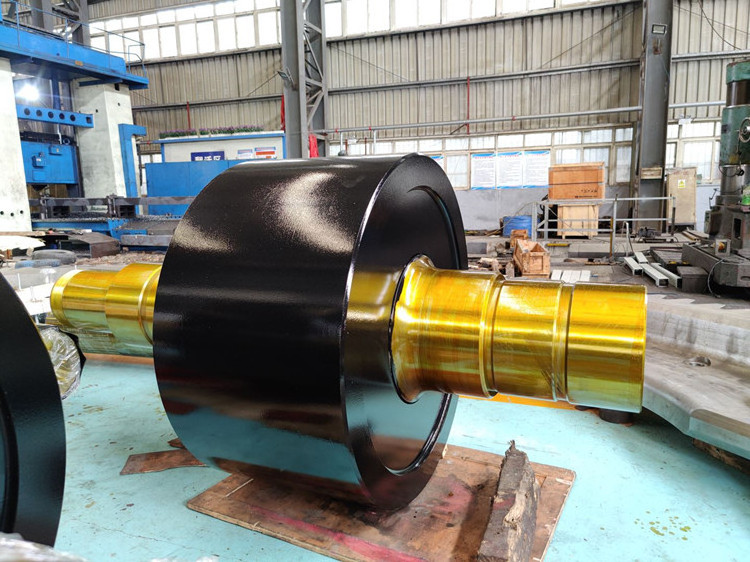

forged roller shafts

-

Forging or casting:

-

forging

-

OEM Service:

-

YES

-

Standard:

-

DIN/GB/AISI

-

Surface treatment:

-

Polishing/Grinding/ Painting/Anti Rust Oil

-

Heat treatment:

-

QT/Hardening/Carburizing

-

Certificate:

-

ISO9001:2015

-

Machining Tolerance:

-

+/-0.01mm

-

Application:

-

Industry/Gearbox/ Transmission Parts

-

Size:

-

Customer's Drawing

Quick Details

-

Weight (KG):

-

50

-

Material:

-

carbon/alloy/stainless steel

-

Torque Capacity:

-

6500

-

Model Number:

-

319

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Ruding

-

Product Name:

-

forged roller shafts

-

Forging or casting:

-

forging

-

OEM Service:

-

YES

-

Standard:

-

DIN/GB/AISI

-

Surface treatment:

-

Polishing/Grinding/ Painting/Anti Rust Oil

-

Heat treatment:

-

QT/Hardening/Carburizing

-

Certificate:

-

ISO9001:2015

-

Machining Tolerance:

-

+/-0.01mm

-

Application:

-

Industry/Gearbox/ Transmission Parts

-

Size:

-

Customer's Drawing

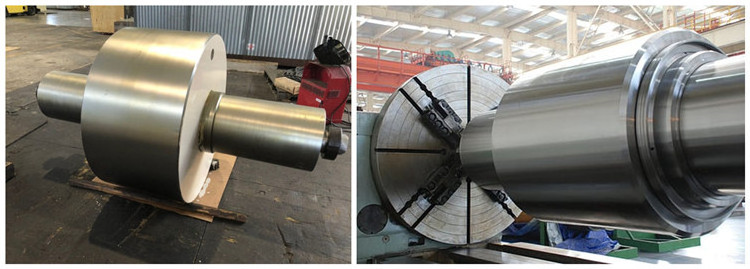

King Steel is a more than 20 - year manufacturer and reputed supplier of forged shaft used in various machinery equipment in the fields of mining, metallurgical, chemical industry, construction, and so on.

King

Steel has manufactured many kinds of forged shafts, including forged roller, forged support roller shafts, forged thrust roller shafts, forged pinion shaft with gears both mounted to the shaft and as a part of the shaft, and other more kinds of forged shafts.

Specification:

|

Material

|

Alloy steel,Carbon steel,Carburizing steel,Quenched and tempered steel

|

|

Heat treatment

|

Normalizing,Annealing,Quenching&Tempering, Surface Quenching,Case hardening

|

|

Machining

|

CNC Turning,CNC Milling,CNC Boring,CNC Grinding,CNC Drilling

|

|

Gear Machining

|

Gear Hobbing,Gear Milling,CNC Gear Milling,Gear Cutting,Spiral gear cutting,Gear Cutting

|

|

Inspection

|

Chemical Composition Test,Ultrasonic Test,Penetration Test,Radiographic Test,Magnetic Test,Tensile Strength Test,Impact

Test,Hardness Test,Dimension Test |

|

Module of Gear

|

8-120

|

|

Gear Grinding

|

MAX. Module 24

|

|

Diameter of Shaft:

|

MAX. 2 200mm

|

|

Length of Shaft

|

MAX. 13 000mm

|

|

Diameter of Gear Wheel

|

MAX.13 000 mm

|

|

Diameter of Spiral Gear

|

MAX. 2 200 mm

|

|

Length of Gear Shaft

|

MAX. 5 000 mm

|

We can customize roller shaft per client's specifications and requirements

Manufacturing process:

Raw material→ Cutting→ Heating→ Heat treatment after forging→ Discharge the furnace→ Machining→ Inspection→ QT→ Inspection→ Finish machining→ Inspection → Packing and Marking→ Storage Shipment.

1. OEM and customized service.

2. Full machining, primer coating, surface treatment.

3. Complete material testing process.

4. Quality control

Please contact us for more information and quotations.