- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2X180KW

-

Dimension(L*W*H):

-

4140*2280*2425mm

-

Weight:

-

14.5t

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Product Name:

-

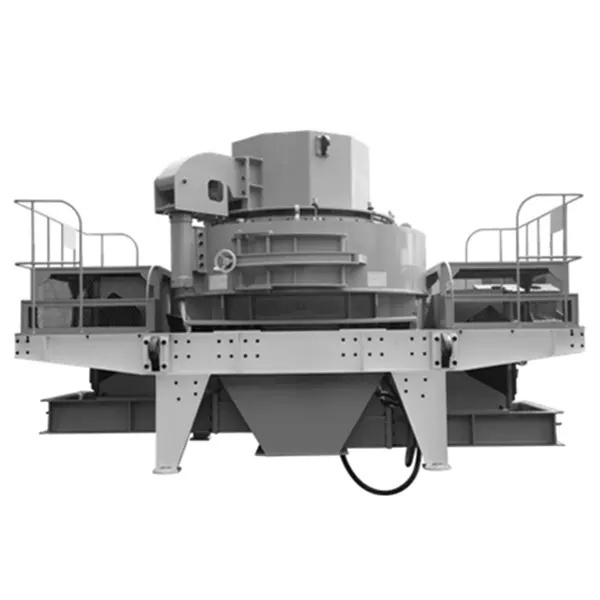

Sand Making Machine

-

Alternative name:

-

Vertical Shaft Impact Crusher, VSI Crusher, Sand Maker

-

After sale service:

-

Spare parts supply

-

Application:

-

Quartz, Granite, Limestone, Basalt etc.

-

Color:

-

Yellow, Blue/Customized

-

Name:

-

VSI8518 sand making machine

-

Usage:

-

Grading

-

Market:

-

Indonesia

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Turkey, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

-

Certification:

-

ISO9001:2000,CE

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UNIQUE

-

Voltage:

-

380v

-

Power:

-

2X180KW

-

Dimension(L*W*H):

-

4140*2280*2425mm

-

Weight:

-

14.5t

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Product Name:

-

Sand Making Machine

-

Alternative name:

-

Vertical Shaft Impact Crusher, VSI Crusher, Sand Maker

-

After sale service:

-

Spare parts supply

-

Application:

-

Quartz, Granite, Limestone, Basalt etc.

-

Color:

-

Yellow, Blue/Customized

-

Name:

-

VSI8518 sand making machine

-

Usage:

-

Grading

-

Market:

-

Indonesia

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Turkey, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

-

Certification:

-

ISO9001:2000,CE

Introduction of our VSI artificial Sand Making Machine

VSI Sand Making Machine is widely used in fine crushing and rough grinding of metal, mineral, building aggregate, concrete, anti-fire material, glass raw material, manufactured sand and all kinds of metallurgical slug. It is also can utilized in shaping of high rank road surface. Compared with other kind of crusher, it is more advanced in intermediate hard, extra hard and abrasive material. Sand Making Machine is improved on the basis of Germany high technology, which is highly-efficient and superior in performance. The Unique VSI Crusher (sand making machine) is widely used to produce sand and stone for highway, high-speed railway, city project, hydropower dam constructions, and concrete mixing plant, and it’s also widely used in sand making and stone reshaping industry.

Features and Benefits

of

Our Sand Making Machine

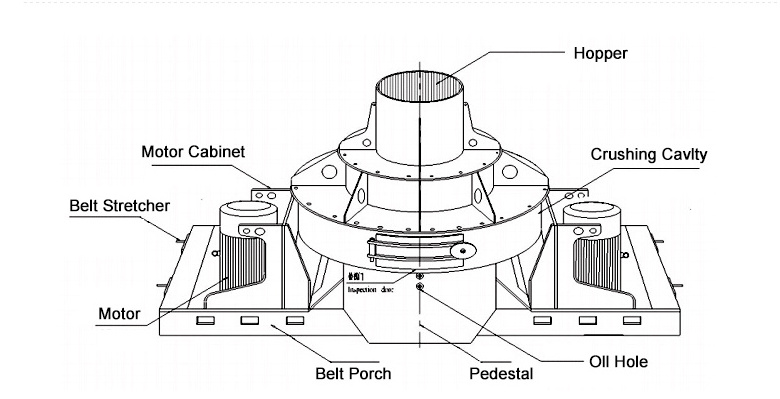

1. The oil needed is supplied by two oil pumps, and the machine stops automatically if there is no oil; the motor can be heated automatically in winter to ensure the normal working of the machine.

2. Hydraulic lifting system to check and replace the spare parts, thus it’s very easy and simple to maintain.

3. The bearing is of SKF and TIMKEN brand to ensure the normal working of the machine.

4. Unique vibrating alarm device: if the machine works abnormally, the alarm will sound to stop the machine, thus protecting the whole machine.

5. Special feeding structure; rock on rock, and rock on iron to make the stones crushed and reshaped.

6. Unique dustproof seal system to prevent the dust getting into the spare parts.

7. Unique design of material bumping angle reduces the friction between raw material and spare parts, extending the working life of spare parts and cut the cost.

8. Low price

Working Principle of Our Sand Making Machine

- Central feeding:Raw materials fall down into the feeding hopper, then enters the impellor through central entrance inlet, thus the material being accelerated by the high-speed impellor and being thrown out at the speed of 60-75m/s. It is crushed when hitting the impact plate, and the end products comes out from the discharging outlet.

- Ring feeding:Raw materials fall down into the feeding hopper, and the materials are divided into two parts by a special plate. Some materials enter the impellor through the center of the plate and the other part of materials falls down from outside of the plate. The materials thrown out earlier crush the materials down from outside, thus the materials crushed and re-crushed.

The Application of Sand Maker

1. River pebbles, rocks (limestone, granite, basalt, diabase, and esite), ore tailings, the artificial sand stone chips.

2. Production of construction aggregate, Highway fabric, cushion material, asphalt concrete and cement concrete aggregate.

3. Production of water conservancy and hydropower engineering, highway, highways, high-speed rail passenger line, bridges, airport runways, municipal engineering, high-rise building mechanisms sand and stone shaping.

4. Material crushing grinding of the mining areas of front-end crushing process, building materials, metallurgy, chemical, mining, refractory, cement, abrasive industry.

5. High abrasive and secondary disintegration broken, thermal power, metallurgy industry, in addition to sulfur, slag, construction waste crushing and other environmental projects.

6. Glass, quartz sand and other high purity materials production

VSI sand making machine

| Model | Capacity(t/h) | Best feed size(mm) | Rototion speed(r/min) | Double motor power(kw) | Demension(mm) | Weight(t) | Power supplier | ||

| feed both at center and at sides | Feed at center | Soft material | Hard material | ||||||

| VSI-7611 | 120-180 | 60-90 | 35 | 30 | 1700-1890 | 110 | 3700*2150*2100 | 11.8 | 380V50HZ |

| VSI-8518 | 200-260 | 100-130 | 40 | 35 | 1520-1690 | 180 | 4140*2280*2425 | 14.5 | |

| VSI-9526 | 300-380 | 150-190 | 45 | 40 | 1360-1510 | 264 | 4560*2447*2778 | 17.8 | |

| VSI-1140 | 450-520 | 220-260 | 50 | 45 | 1180-1310 | 400 | 5000*2700*3300 | 25.6 | |

PL sand making machine

|

Model |

Max. Feed Size (mm) |

Impeller Speed (r/min) |

Capacity (t/h) |

Power (kW) |

|

PL700 |

45 |

1700-2000 |

30-60 |

75-90 |

|

PL800 |

55 |

1400-1620 |

50-90 |

110-150 |

|

PL900 |

65 |

1330-1530 |

80-150 |

180-264 |

|

PL105 0 |

80 |

1200-1400 |

150-250 |

264-320 |

|

PL1250 |

100 |

1000-1100 |

250-500 |

440-500 |

|

PL1300 |

100 |

1000-1100 |

500-700 |

500-640 |

VSI high efficiency sand making machine

Pl series series sand making machine

Packaging

:standard Container Packs or in Bulk.The electrical motor or spare parts will be packed by wooden case or steel frame.Unique offers various ways of package, fumigation-free wooden cases, steel plate cases, or as the clients' request. Most of the time, the equipment will be loaded to the containers in the factory. Unique workers make sure all equipment are steady and fixed before close the door of the container, there will be no damage during transporation and shipment.

Shipping

:we deliver the cargo to China's main sea ports,such as Qingdao,Tianjin,Shanghai etc.And then the container will be transported to your country by sea.

After-sales service support

1.more than 12 months' warranty period

2.Erection and Commissioning

3.Operator Training

4.Spare Parts Supply

Normally,Equipment spares will be offered with manufacturing cost in at least 10 years since the order is placed. To establish long term cooperation, we will regularly call and email our clients, to check the equipment working condition, offer suggestions for maintenance, and if necessary we will pay a visit to clients to solve the problems caused during equipment working.

Delivery Time : 20~30 days after receiving advanced payment .

Products Certificate : TUVRheinland CE , ISO9001:2000