- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer' request

-

Dimension(L*W*H):

-

6000*1500*1300mm

-

Weight:

-

5500 kg

-

Feeding width:

-

1200mm or customer's need

-

Marketing Type:

-

Hot products

-

Product name:

-

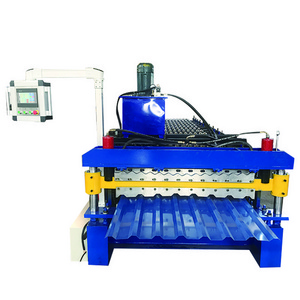

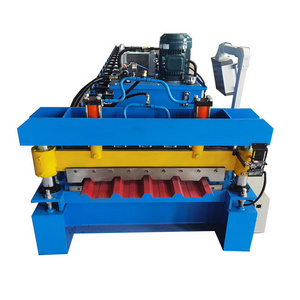

Double Layer Roofing Sheet Machine

-

Color:

-

Customized

-

Main motor power:

-

3kw, 3 phase

-

Hydraulic motor power:

-

4kw

-

Backboard Thickness:

-

14mm

-

Chain Size:

-

20mm

-

Feeding Thickness:

-

0.3-0.8mm

-

Roller Diameter:

-

80mm

-

Cutter material:

-

Cr12 , quenched

-

Material of shafts:

-

High grade 45#,with heat treatment

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

15-25 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer' request

-

Dimension(L*W*H):

-

6000*1500*1300mm

-

Weight:

-

5500 kg

-

Feeding width:

-

1200mm or customer's need

-

Marketing Type:

-

Hot products

-

Product name:

-

Double Layer Roofing Sheet Machine

-

Color:

-

Customized

-

Main motor power:

-

3kw, 3 phase

-

Hydraulic motor power:

-

4kw

-

Backboard Thickness:

-

14mm

-

Chain Size:

-

20mm

-

Feeding Thickness:

-

0.3-0.8mm

-

Roller Diameter:

-

80mm

-

Cutter material:

-

Cr12 , quenched

-

Material of shafts:

-

High grade 45#,with heat treatment

Products Description

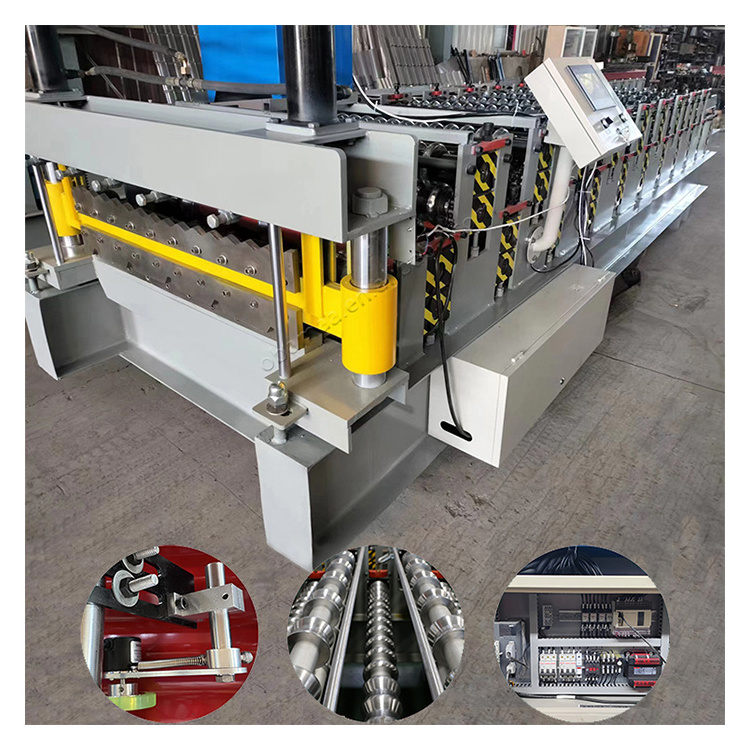

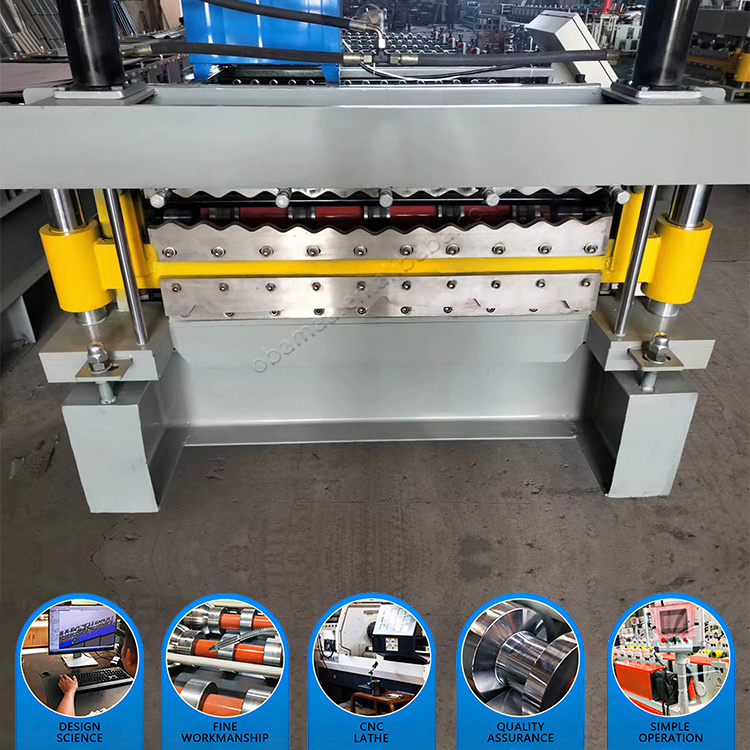

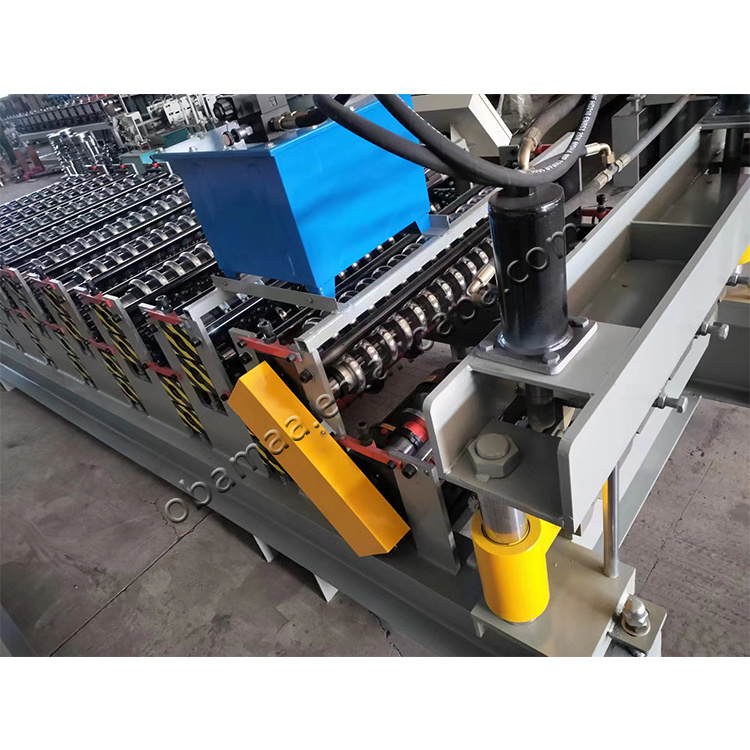

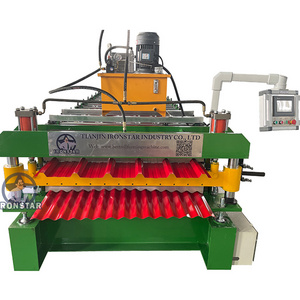

Double Layer Roof Sheet Roll Forming Machine

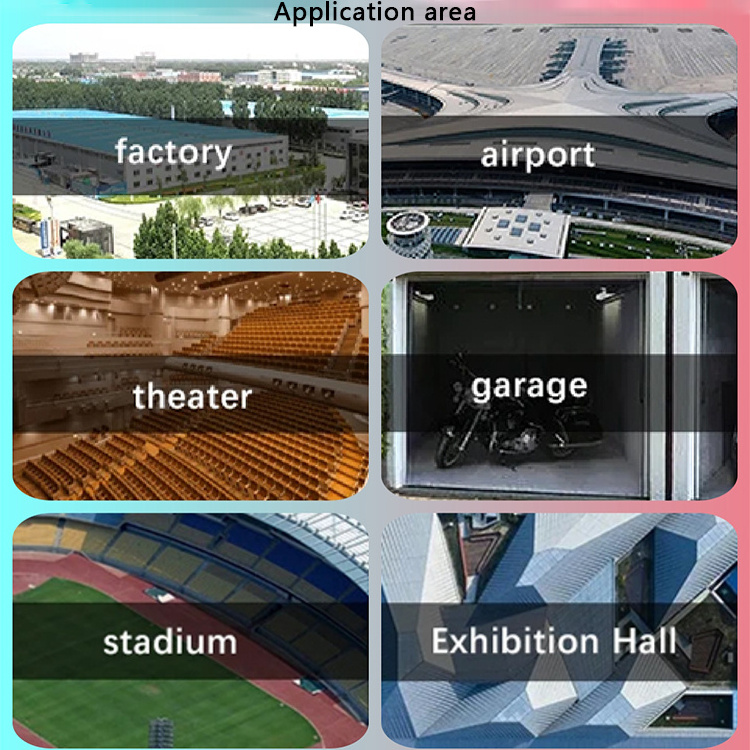

The color steel tiles produced by the double-layer tile pressing machine have a flat appearance, uniform ripple, high utilization rate, high strength, high degree of production automation, low cost, and durability. The products are widely used in civil buildings of large and medium-sized enterprises, such as factories, locomotive hangars, aircraft hangars, sports venues, exhibition halls, cinemas, etc.

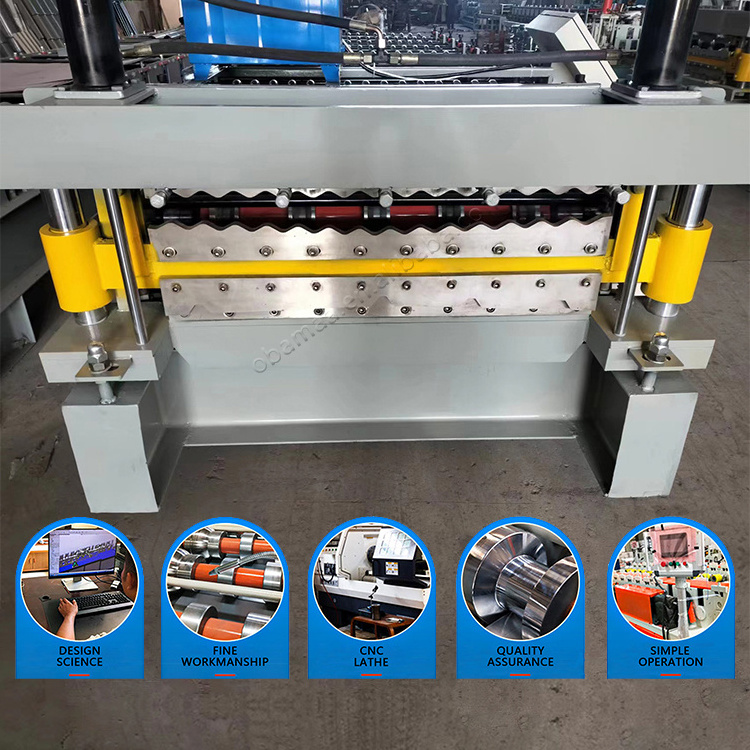

Work processing

Processing Flow

Uncoiling → Feeding material into machine →Roll forming → Auto cutting →Products receiving table

Specification

|

Double Layer Roof Sheet Roll Forming Machine

|

|

|

|

|||

|

SN

|

Part details

|

Item

|

Specification

|

|||

|

1

|

Material

|

Raw material

|

Colored Steel

|

|||

|

|

|

Thickness

|

0.3-0.8 mm

|

|||

|

2

|

Machine

|

Roller station

|

Depend on customer' drawing

|

|||

|

|

|

Shaft diameter

|

70 mm

|

|||

|

|

|

Shaft material

|

45# steel with 0.05mm chrome

|

|||

|

|

|

Roller material hardness 30-40 HRC

|

45# steel with 0.05mm chrome

|

|||

|

|

|

Machine size

|

About 6×1.5×1.3 m

|

|||

|

|

|

Machine weight

|

About 5.5 ton

|

|||

|

|

|

Machine color

|

As customer' request

|

|||

|

|

|

Working speed

|

10-25 m/min

|

|||

|

3

|

Cutter

|

Hardness

|

50-65 HRC

|

|||

|

|

|

Cutting tolerance

|

± 1 mm

|

|||

|

|

|

Material

|

Cr 12

|

|||

|

|

|

Operate

|

Hydraulic cutting

|

|||

|

4

|

Power

|

Driving way

|

Chain 1 inch

|

|||

|

|

|

Main power

|

7.5 kw

|

|||

|

|

|

Pump power

|

4kw

|

|||

|

|

|

Voltage

|

Customize as customer' request

|

|||

|

5

|

Control system

|

PLC brand

|

Delta or Customize as customer' request

|

|||

|

|

|

Screen

|

Touchable screen

|

|||

|

|

|

Language

|

English or add language as customer need

|

|||

|

6

|

Decoiler

|

Operation

|

Manual

|

|||

|

|

|

Weight capicatity

|

5 ton

|

|||

|

|

|

Price

|

Free as gift

|

|||

|

7

|

Receiving table

|

Operation

|

Manual

|

|||

|

|

|

Length

|

3 m

|

|||

|

|

|

Price

|

Free as gift

|

|||

Product Details

5T Manual Decolier For Free

Capacity:

5 tons

Coil inner diameter:

450-550mm

Feeding width:

max 1220mm

Structure: welded by the steel plates and profiled bar.

The shrink and expand of core is manually, with manual brake,The coil moving forward or reverse is pulled by roll forming machine.

The shrink and expand of core is manually, with manual brake,The coil moving forward or reverse is pulled by roll forming machine.

Feeding Device

Hand wheels on both sides can be used to adjust the feeding width.

Touch stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

PLC Control Box

Operating language:English and Chinese(or as requested) You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.

Hydraulic Pump Station

Hydraulic station motor:

4 KW

Hydraulic oil:

46# hydraulic oil

Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve.

Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve.

Fully automatic computer operation, easy to use, convenient and responsive.

The frame structure is welded with carbon steel plates, which has a long service life.

Low noise operation and short flattening time.

Good bearing capacity and easy operation.

Carefully selecting materials is the key to making good products.

On demand production, welcome to customize with pictures.

Glazed Type

Roll Forming Sheet

Corrugated Type Roll Forming Sheet

IBR Type Roll Forming Sheet

Roofing sheet has many different shapes,usually different countries have its own popular design ,we can customize the machine as customers’ demand.

Q1. How do I choose the right machine for me?

1. A machine doesn't just provide a few photos to prove what they can produce .

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

Q2. You did not display the product I need. Can you produce it?

Our engineers have studied at well-known European companies and have significant advantages in mechanical design, research and development, and manufacturing.

Q3. How long can the machine be built?

Generally speaking, the machine takes about 20 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate,and have a longer service life. The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, to be a service company that you have the strength to guarantee.

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don't have your own outline drawing, we can recommend some models according to your local market standard.

Generally speaking, the machine takes about 20 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate,and have a longer service life. The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, to be a service company that you have the strength to guarantee.

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don't have your own outline drawing, we can recommend some models according to your local market standard.

Hot Searches