- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Tmeasurement

-

Model Number:

-

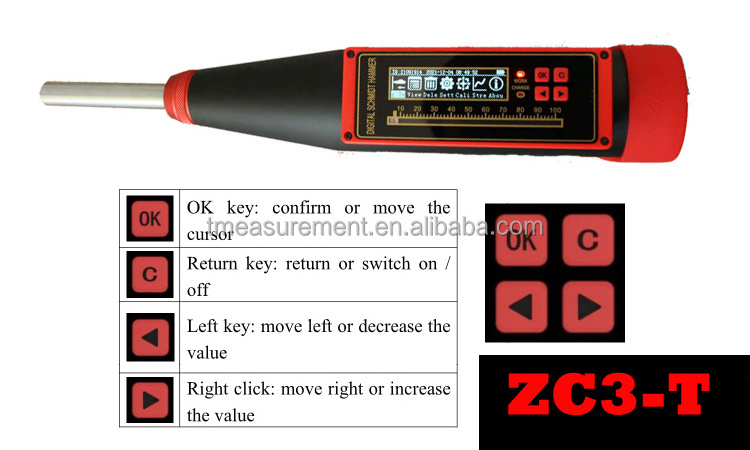

ZC3-T

-

Nominal kinetic energy:

-

2.207J

-

Stiffness of spring:

-

785 ± 30.0N/m

-

Pointer length:

-

20.0 ± 0.2mm

-

Pointer friction:

-

0.65 ± 0.15N

-

Spherical radius of impact rod:

-

R25 ± 1.0mm

-

Rated value of steel anvil:

-

80 ± 2

-

Operating temperature:

-

- 4 ℃ ~ + 40 ℃

-

Communication rate:

-

115200bps

-

Working hours:

-

continuous working ≥ 10 hours

-

Test range:

-

10-60MPa

Quick Details

-

Warranty:

-

18 Months

-

Power:

-

Electronic

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

Tmeasurement

-

Model Number:

-

ZC3-T

-

Nominal kinetic energy:

-

2.207J

-

Stiffness of spring:

-

785 ± 30.0N/m

-

Pointer length:

-

20.0 ± 0.2mm

-

Pointer friction:

-

0.65 ± 0.15N

-

Spherical radius of impact rod:

-

R25 ± 1.0mm

-

Rated value of steel anvil:

-

80 ± 2

-

Operating temperature:

-

- 4 ℃ ~ + 40 ℃

-

Communication rate:

-

115200bps

-

Working hours:

-

continuous working ≥ 10 hours

-

Test range:

-

10-60MPa

Product Description

ZC3-T The component list of digital rebound test hammer mainly includes 1 Mechanical rebound test hammer, 1 electronic detection system, 1 charger, 1 Micro USB data cable,1 USB flash disk and 1 product operation manual.

Performance Characteristics

Built in national unified curve (JGJ/T23-2011) and multiple provincial,municipal and district local strength measurement curves, support real-time measurement point strength estimation, and automatically calculate the measurement area strength and component estimated strength after sampling

Compliance standard: Industry Standard of the People's Republic of China rebound test hammer (JJG 817-2011)

Small size, modular design, easy to replace the mechanical rebound test hammer

Small size, modular design, easy to replace the mechanical rebound test hammer

Built in large capacity rechargeable lithium ion battery, long service life of the test hammer

Built in large capacity memory can store 999 standard components, and a single component can set up 99 measuring areas and 159840 measuring point data at most

Support break-point continuous test, and data collection is more convenient and humanized

Support voice counting, measurement area conversion and component completion voice

reminder

reminder

Support Bluetooth online, expand the use of mobile app connection, and make it more convenient to upload data to the cloud with the cloud server

Through data line connection and computer data processing software, the test data can be processed quickly and the test report can be issued

Support system upgrade. According to user feedback, the company will upgrade the system

regularly to improve the use experience

regularly to improve the use experience

Technical parameters

|

Nominal kinetic energy

|

2.207J

|

|

Stiffness of spring

|

785 ± 30.0N/m

|

|

Pointer length

|

20.0 ± 0.2mm

|

|

Pointer friction

|

0.65 ± 0.15N

|

|

Spherical radius of impact rod

|

R25 ± 1.0mm

|

|

Working length of spring striking tension spring

|

61.5 ± 0.3mm

|

|

Tensile length of spring striking tension spring

|

75.0 ± 0.3 mm

|

|

Rated value of steel anvil

|

80 ± 2

|

|

Consistency of detection indication

|

≤± 1

|

|

Operating temperature

|

- 4 ℃ ~ + 40 ℃

|

|

Communication rate

|

115200bps

|

|

Display

|

2.08-inch 256x64 (dot matrix) OLED display

|

|

Power supply

|

1800mAh, 3.7V lithium ion battery

|

|

Working hours

|

continuous working ≥ 10 hours

|

|

Test range

|

10-60MPa

|

Related Products

HT-225 Concrete Test Hammer

The concrete rebound hammer are the most widely used portable NDT measuring instruments for a rapid assessment of the condition of a concrete structure

TEM912 Concrete Test Hammer

TEM912&TEM91

Series DIGITAL TEST HAMMER automatically Record, Save, Calculate and Processing data.

Precautions

1. Although the test hammer can save the tested original test data in large capacity and for a long time, due to the importance and non repeatability of the original test data, please export the test data saved by the test hammer in time and backup it. Maintaining the good operation performance of the mechanical part of the digital rebound test hammer is the basis to ensure the normal use of the test hammer. Therefore, the mechanical part of the rebound test hammer needs to be maintained regularly. The sensor must be disassembled in strict accordance with the requirements of the maintenance guide in this manual, otherwise the mechanical parts of the sensor, especially the electronic devices, will be damaged. In the actual detection, it should be noted that the bounce frequency of the digital rebound test hammer should not be too fast, and the time interval of the second bounce should not be less than 1 second, so as to avoid the impact on the sampling accuracy caused by the bounce of the sensor tension spring when it has not been completely reset. In the actual detection, the comparison between the manual mechanical reading and the digital display value of the test hammer is often carried out, which is helpful to find the operation fault of the sensor in time and avoid the distortion of the detection data. Please do not put heavy objects on the test hammer to avoid key failure due

to long-term compression and deformation; Avoid placing or storing the test hammer in strong sunlight or high temperature environment, and avoid storing the test hammer in humid or dusty environment.

to long-term compression and deformation; Avoid placing or storing the test hammer in strong sunlight or high temperature environment, and avoid storing the test hammer in humid or dusty environment.

2. Do not place the test hammer near magnets, motors or other equipment that will produce strong magnetic fields, and do not use the test hammer in an environment with strong magnetic fields. Exposure to strong magnetic field may cause abnormal operation of the test hammer or damage the test data stored in the test hammer.

3.Please do not bring the test hammer from high-temperature environment to low-temperature environment or from low-temperature environment to high-temperature environment in a short time, which may cause water vapor condensation on the internal and external surfaces of the test hammer. You can avoid this problem by placing the test hammer in a plastic bag and

gradually adjusting it to the ambient temperature before use. If condensation occurs, please stop using the test hammer. Continued use may cause damage to the test hammer.

gradually adjusting it to the ambient temperature before use. If condensation occurs, please stop using the test hammer. Continued use may cause damage to the test hammer.

4. When the test hammer is not used for a long time, please charge it frequently to avoid the battery entering into self-protection due to ultra-low voltage due to long-term use of the test hammer, which hinders normal use and causes damage to the test hammer.

Hot Searches