- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DZJX

-

Voltage:

-

110V220V230V380V400V415V440V500V600V/50HZ60HZ

-

Dimension(L*W*H):

-

customized

-

Weight:

-

200 KG

-

Material:

-

Stainless Steel/carbon steel

-

Mesh cleaning:

-

rubber ball/silica ball/ultrosonic device

-

Amplitude:

-

20---70mm

-

Layer(s):

-

1-4 layers

-

Frenquency:

-

220---280 rpm

-

Motor:

-

electric motor

-

Noise Level:

-

75 db

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Free spare parts, Online support, Video technical support, Field installation, commissioning and training, Field maintenance and repair service

-

Certification:

-

CE ISO

Quick Details

-

Type:

-

Circular

-

Marketing Type:

-

Hot Product 2020

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DZJX

-

Voltage:

-

110V220V230V380V400V415V440V500V600V/50HZ60HZ

-

Dimension(L*W*H):

-

customized

-

Weight:

-

200 KG

-

Material:

-

Stainless Steel/carbon steel

-

Mesh cleaning:

-

rubber ball/silica ball/ultrosonic device

-

Amplitude:

-

20---70mm

-

Layer(s):

-

1-4 layers

-

Frenquency:

-

220---280 rpm

-

Motor:

-

electric motor

-

Noise Level:

-

75 db

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Free spare parts, Online support, Video technical support, Field installation, commissioning and training, Field maintenance and repair service

-

Certification:

-

CE ISO

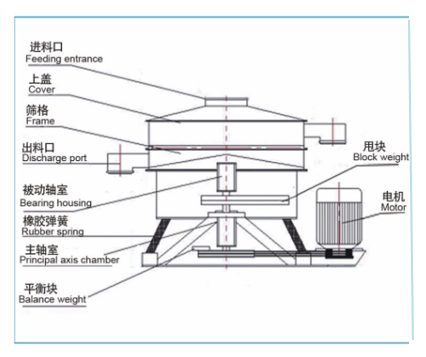

Product Description

DZJX series swing screening machine is a kind of inertial equipment with mature technology and classical application.Its new design Philosophy and unique structure making it the closest manual screen machine. The Tumbler screening machine have bright application prospects for its perfect screening effect. From the aspect of its trajectory, it is a non-linear inertial vibrating screen. The Tumbler screening machine is particularly used to classify small materials and fine powder according to its unique structure and working principle. It is not only apply to dry sieving, but also wet sieving.

Working principle

The machine is drived by a unbalance motor, which is with variable eccentric weights on both sides of motor shaft, The screening time and movement of material on the screen surface can be controlled by adjusting the angle of the two eccentric weights.

Application

--Metallurgy and mining industry: quartz sand, sand, ore, titanium oxide, zinc oxide, etc.

--Paper-making industry:coated slurry, exhaust liquid, paper making liquid and waste water reclamation, etc.

--Chemical industry: resin pigment, calcium carbonate, decorative coatings, medicine, grease, paint, palette, etc.

--Abrasive material and ceramic industry: building sand, mica, alumina, silica sand, abrasive, refractory material, slurry, etc.

--Mechanical industry: casting sand, charcoal, grafito, powder metallurgy, electromagnetic material and metal powder, etc

--Food industry: sugar, salt, alkali, flour powder, nut powder, farina, gourmet powder, starch, milk powder, yeast powder,

pollen,food additive, bean milk, juice, etc.

pollen,food additive, bean milk, juice, etc.

Size Information

|

Model

|

Screen mesh area(m²)

|

Frequency (r/min)

|

Granularitysize

(mm) |

Amplitude(mm)

|

Power(kw)

|

|

DZYS-600

|

0.28

|

220-280

|

≤100

|

20-70

|

0.75

|

|

DZYS-1000

|

0.66

|

220-280

|

≤100

|

20-70

|

1.5

|

|

DZYS-1200

|

0.98

|

220-280

|

≤100

|

20-70

|

2.2

|

|

DZYS-1500

|

1.67

|

220-280

|

≤100

|

20-70

|

3.0

|

|

DZYS-1800

|

2.37

|

220-280

|

≤100

|

20-70

|

4.0

|

|

DZYS-2000

|

2.89

|

220-280

|

≤100

|

20-70

|

4.0

|

|

DZYS-2600

|

5.3

|

220-280

|

≤100

|

20-70

|

5.5

|

Details Images

Customized construction deck

According to the needs of the buyer, the number of swing screen layers can be customized. At present, our factory supports the customization of one to four layer swing screen.

Customized construction material

Stainless steel material is the first choice for medical grade and food grade buyers, carbon steel is the first choice for cost saving, contact with stainless steel can not only meet the health requirements, but also save costs.

Packing&Shipping

Company Introduction

We are direct factory of Vibrating Screen, Conveyor equipment and Mixer for many years, we are glad to build longlasting business relationship with you.

We have the enterprising and energetic team of excellence who are dedicated to their career. More than 200 staff work for us, including 65 technicians and engineers with senior title . In 2000, we established CAD workstation earlier than others in China.

We have the enterprising and energetic team of excellence who are dedicated to their career. More than 200 staff work for us, including 65 technicians and engineers with senior title . In 2000, we established CAD workstation earlier than others in China.

FAQ

Q: What information do we need to help you choose a perfect machine?

1. Name and feature of the raw material

2.Aim of using: get rid of impurity, filtration, grading

3.granularity distribution

4.Handling capacity: kg /h, L/h

5.The raw material size: (mesh or mm)

6.The moisture of the material

7.The material of construction (stainless steel SUS 304 or 316, carbon steel Q 235 A)

8.How many layers you need?

9.The voltage , frequency, phase (single or three)

Note: You'd better send us the relevant pictures or some materials you want to sift , it can assure us to recommend the suitable machine for you.

Q:Can I ask some special and customize design?

A: Yes, we can make a suitable machine for you according to your request.

1. Name and feature of the raw material

2.Aim of using: get rid of impurity, filtration, grading

3.granularity distribution

4.Handling capacity: kg /h, L/h

5.The raw material size: (mesh or mm)

6.The moisture of the material

7.The material of construction (stainless steel SUS 304 or 316, carbon steel Q 235 A)

8.How many layers you need?

9.The voltage , frequency, phase (single or three)

Note: You'd better send us the relevant pictures or some materials you want to sift , it can assure us to recommend the suitable machine for you.

Q:Can I ask some special and customize design?

A: Yes, we can make a suitable machine for you according to your request.

Hot Searches