- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

2200

-

Power (kW):

-

2.2

-

Colour:

-

blue,green,etc

-

Total pressure:

-

3.15-28 MN

-

Plate clearance:

-

200-400 mm

-

Piston stroke:

-

400 mm

-

Working layer number:

-

1-2

-

Plate pressure:

-

22-35 Mpa

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Eenor

-

Voltage:

-

according client's requirement

-

Weight:

-

2200

-

Power (kW):

-

2.2

-

Colour:

-

blue,green,etc

-

Total pressure:

-

3.15-28 MN

-

Plate clearance:

-

200-400 mm

-

Piston stroke:

-

400 mm

-

Working layer number:

-

1-2

-

Plate pressure:

-

22-35 Mpa

Description:

- With completely sealed condition, materials are mixed or plasticated under certain pressure, controllable temperature, which makes high production efficiency and obtains excellent stable quality.

- Spiral angle and over lapping length of the blades of the rotors are of reasonable design and make the materials to be dispersed uniformly.

- Surface where is contacted with the materials are all plated with hard chromium and polished, which is corrosion-resistant and wear-resistant.

- Jacket construction is adopted in parts that surfaces contacted with materials to achieve excellent water-cooling or steam heating effect and fit in with the needs of plastics and rubber processing technology.

- Feeding from back door on the frame (oranother top door) is convenient for continuous process operation in a production line. The mixing chamber is able to turn forward by 140 around the front rotors to discharge and is easy for changing pigments and cleaning the chamber.

Technical Parameters:

|

Type |

XLB-DQ1200×1200×2 |

XLB-DQ1300×2000×1 |

XLB-Q1200×2500×1 |

XLB-Q1500×2000×1 |

XLB-Q2000×3000×1 |

XLB-Q1400×5700×1 |

|

Total pressure(MN) |

315t |

560t |

750t |

1000t |

1800t |

2800t |

|

Plate size(mm) |

1200×1200 |

1300×2000 |

1200×2500 |

1500×2500 |

2000×3000 |

1400×5700 |

|

Daylight(mm) |

200 |

400 |

400 |

400 |

400 |

400 |

|

Layer |

2 |

1 |

1 |

1 |

1 |

1 |

|

Piston stroke(mm) |

400 |

400 |

400 |

400 |

400 |

400 |

|

Plate unit area pressure (kg/ cm2) |

22 |

21.5 |

25 |

33.5 |

30 |

35 |

|

Main motor power(KW) |

3 |

8 |

9.5 |

11 |

26 |

43.5 |

|

Overall dimension (L×W×H)(mm) |

1685×1320×2450 |

2000×1860×2500 |

2560×1700×2780 |

2810×1550×3325 |

2900×3200×2860 |

2400×5800×3600 |

|

Weight (kg) |

9500 |

17000 |

20000 |

24000 |

66000 |

110000 |

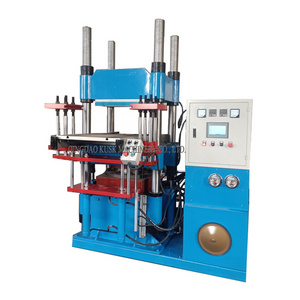

Pictures of machine:

Full Automatic Plate Vulcanizing Machine

Certification:

Our company is a firm engaged in production enterprise, mechanism of rubber has more than 20 years of history.

Companies depend on the technical power, the strict scientific management expertise, product quality and good service, and won the majority of the customer's trust. many of the product is exported to the united states, canada, australia and india, indonesia and uzbekistan, etc.

Company management certification: ISO 9001:2000, ISO 17799, ISO 9001:2008, ISO 14001:2004, ISO/TS 16949

Our main products are plate vulcanizing press, two-roll mixing mill, rubber extruder, banbury intensive kneader, bale cutter, conveyer belt vulcanizing press, tyre reclaiming machines, rubber refiner, rubber cracker, etc. we especially specialize in the design and manufacture of the nonstandard products .

(1)Train how to operate and maintain the equipment, we can also offer a house call to install and debugging.

(2)Provide the formers of many specifications, and we can make according to your demand.

(3)Guarantee to keep the machine in good repair.

1.Q:Are you a factory or trading company?

A:We are factory,passed CE,BV certification.

2.Q:Where is your factory?How can i visit ?

A:Our factory located in qingdao city.You can fly to qingdao liuting airport,then we can pick you up to our facotry to visit.Warm welcome visit us.

3.Q:How does your factory control the quality of machines and after sales service?

A:Our machines passed CE,BV,ISO,SGS certification,pls confirm the quality.All our machines have 1 year guarantee, will provide lifetime maintenance.