- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DiMei

-

Model Number:

-

DM212

-

Type:

-

Liquid Glue, Non-sovent

-

Product name:

-

Concrete Joint PU Sealant

-

Color:

-

Grey, White, Other colors customized

-

Shelf life:

-

9 Months

-

Other Name:

-

PU sealant

-

Application:

-

Concrete Road Wall Joint Gap Filling

-

Material:

-

Polyuerthane

-

Certificate:

-

ISO9001

-

Appearance:

-

Smooth Paste

-

Packing:

-

20pcs/CTN

Quick Details

-

CAS No.:

-

7085-85-0

-

Other Names:

-

PU sealant

-

MF:

-

C10H8N2O2.C6H14O3)x

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DiMei

-

Model Number:

-

DM212

-

Type:

-

Liquid Glue, Non-sovent

-

Product name:

-

Concrete Joint PU Sealant

-

Color:

-

Grey, White, Other colors customized

-

Shelf life:

-

9 Months

-

Other Name:

-

PU sealant

-

Application:

-

Concrete Road Wall Joint Gap Filling

-

Material:

-

Polyuerthane

-

Certificate:

-

ISO9001

-

Appearance:

-

Smooth Paste

-

Packing:

-

20pcs/CTN

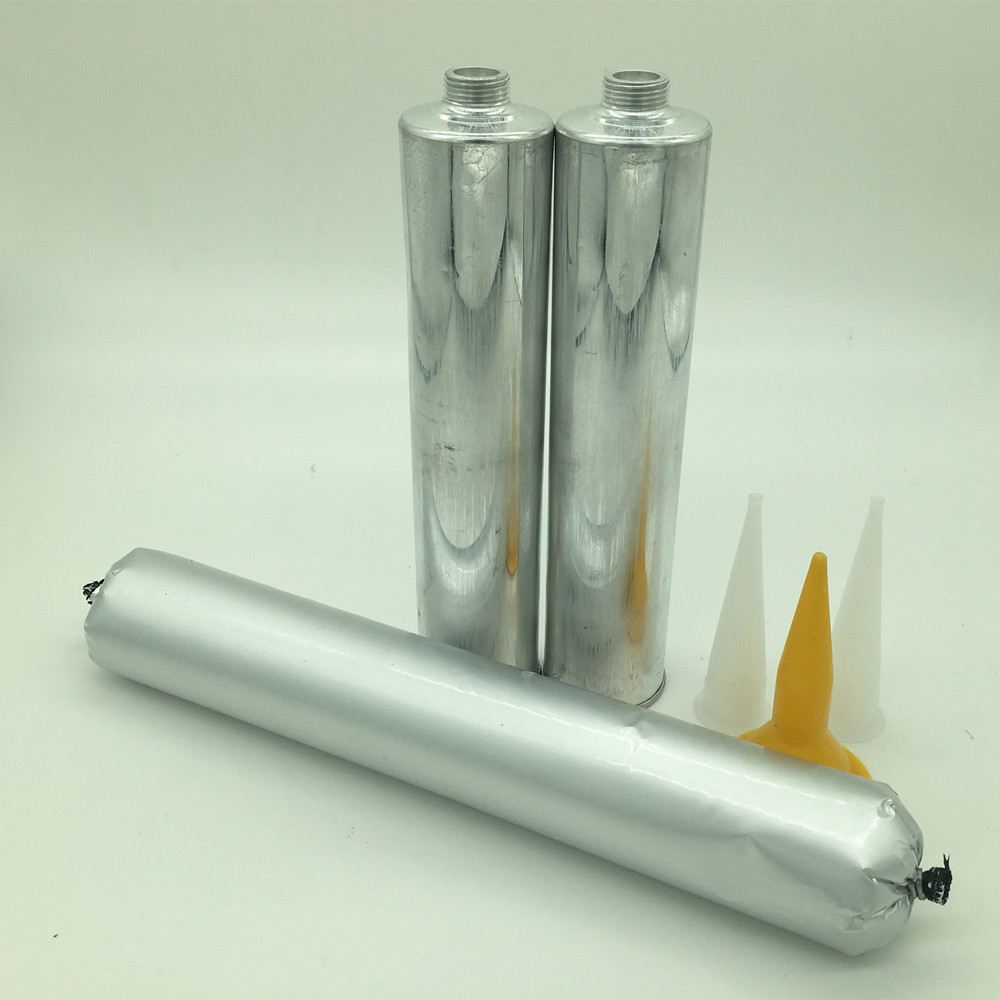

DiMei Factory Supply One Component 600ml Sausage Liquid Adhesive Concrete Road Wall Gap Polyurethane Liquid Rubber

Substrate: PU p olymer

DM212 is a one-component polyurethane sealant based on PU polymers , m oisture curing type. The curing speed of mortar is related to the temperature and humidity of the environment. Under high-temperature or high-humidity conditions, it will be quickly crusted. Low-temperature and low-humidity will delay the curing process. The final curing time is also related to the thickness of the glue applied .

DM212 is a special sealant for interior decoration, with moderate modulus, good thixotropy, moderate elongation, good elasticity, suitable for all kinds of porous and non-porous materials, with good adhesion, surface coating paint is available. It is a professional sealant that is specially used for interior decoration. It is cost-effective and can be used in interior decoration to replace traditional silicone sealant . It can also be used in industrial applications where white sealant is required.

Features & Advantages

l White, grey, beige colors available, other colors can be customized.

l Odorless, low VOC, PVC free, safe to use.

l Good resistance to cold and hot weather alternation, over 10 years of service life.

l After curing, the shrinkage rate is very low, and the Thixotropy is good, the form during construction can be maintained well.

l It can be applied for the sealing of all kinds of interior decoration materials in the room.

l Low temperature resistance, in the range of -40 ℃ ~ 90 ℃ , can maintain good flexibility and adhesion.

l No primer required.

Typical application s

DM212 is suitable for the elastic sealing of most substrate joints, including stainless steel, aluminum, copper, PVC, polyester, ceramics, wood, coating, etc. It is widely used for the sealing of various seams in interior decoration and waterproof treatment.

TDS

|

Indicator |

Parameter |

|

Color |

White, Grey, Beige, etc |

|

Outer appearance |

Paste |

|

Density, g/cm³ |

1.44±0.03 |

|

Consistency |

7.0±0.2 |

|

Hardness, Shore A |

48±2 |

|

Extrusion. ml/min |

≥ 120 |

|

Sag rate, mm |

0 |

|

Surface dry time, min |

25-40 |

|

Curing speed, mm/24h |

3.0-5.0 |

|

Peel adhesion, Cohesive destruction, % |

≥ 70 |

|

Elongation at break, % |

≥ 450 |

|

Tensile Strength, Mpa |

≥ 1.4 |

|

Breaking strength, Kn/m |

≥ 15 |

Test under situation: 23℃×50%RH×28days.

Application field: Concrete Road, Wall Joint Gap filling, bonding with elsticity

Typical application s

DM221 is suitable for elastic sealing of various substrate joints, including stainless steel, aluminum, copper, PVC, polyester, ceramics, wood, coating, etc., but not suitable for PP and PTFE materials. It plays the role of bonding, sealing, shock absorption and waterproofing in the automotive industry.

Application area

l It can be used for bonding, sealing, shock absorption and waterproofing of glass and metal sheet such as cars, passenger cars, new energy vehicles, construction vehicles, electric vehicles, and modified cars. It can also be used to fill gaps between metal sheet and metal sheet, as material of sealing and waterproofing.

l Other industrial or residential applications that require bonding, sealing, shock absorption, and waterproofing.

Application tips

l The bonded surface must be clean, dry and free of putty before bonding.

l Substrates that may seep out of oil are not suitable for direct application of sealant.

l For rusted or corroded metal surfaces (such as aluminum oxide, copper, iron oxide rust surface), in order to ensure the bonding effect, the rust on the surface layer needs to be worn off before coating.

l Due to the construction environment, construction methods, and material differences, pre-testing is required before use to ensure adhesion performance.

l The optimal coating temperature is +15 ~ +40°C. When the temperature is low, the extrusion resistance increases, warm up the adhesive before use.