- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v/customized

-

Dimension(L*W*H):

-

650*650*600mm

-

Weight:

-

100 KG

-

Product name:

-

Scraper rotary vibrating screen for sulfur powder

-

Keyword:

-

vibrating screen

-

Motor:

-

Vertical Vibrating Motor

-

Material:

-

Carbon Steel/ Stainless Steel 304

-

Usage:

-

Fine Particles Screening

-

Function:

-

Screening\separation\sorting\sieving

-

Layer(s):

-

1-4 Layers

-

Capacity:

-

Recommended Suitable Model

-

Service:

-

Timely

-

Noise:

-

Low Noise

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DY

-

Voltage:

-

380v/customized

-

Dimension(L*W*H):

-

650*650*600mm

-

Weight:

-

100 KG

-

Product name:

-

Scraper rotary vibrating screen for sulfur powder

-

Keyword:

-

vibrating screen

-

Motor:

-

Vertical Vibrating Motor

-

Material:

-

Carbon Steel/ Stainless Steel 304

-

Usage:

-

Fine Particles Screening

-

Function:

-

Screening\separation\sorting\sieving

-

Layer(s):

-

1-4 Layers

-

Capacity:

-

Recommended Suitable Model

-

Service:

-

Timely

-

Noise:

-

Low Noise

hemp protein powder rotary vibrating screen for sulfur powder

Product Description

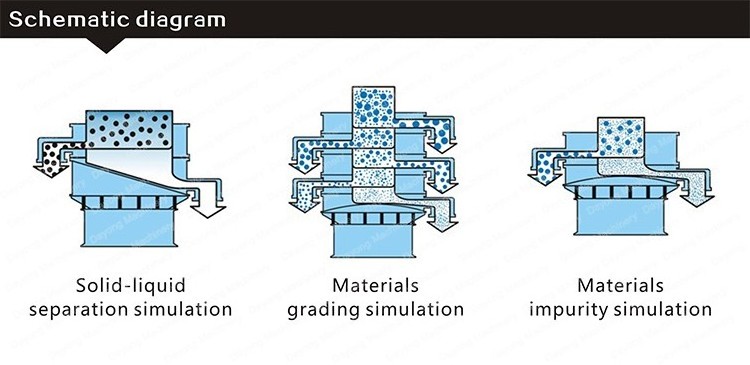

Operating Principle

Its vertical motor, which is installed with eccentric hammers on the top and bottom, regarded as a vibratory source. The eccentric hammers change the track of rotation in to horizontal, vertical and inclined movement, and then pass the movement to the sieving surface. Adjusting the phase angle between the top and bottom eccentric weight can change trajectories of the materials on the sieve.

Applications

1) Chemical industry: resin pigment, medicine, grease, paint, palette, etc.

2) Abrasive material and ceramic industry: building sand, mica, alumina, abrasive, refractory material, slurry, etc.

3) Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice.

4) Paper-making industry: coated slurry, exhaust liquid, paper making liquid and waste water reclamation, etc.

5) Metallurgy and mining industry: quartz sand, ore, titanium oxide, zinc oxide, etc.

Technical Parameter

|

Model

|

Power (kw)

|

Valid Diameter of screen (mm)

|

Volume (mm)

|

Layers

|

|

DY-600-1S

DY-600-2S

DY-600-3S

|

0.55kw

|

550mm

|

800*800*680

800*800*780

800*800*880

|

1

2

3

|

|

DY-800-1S

DY-800-2S

DY-800-3S

|

0.75 kw

|

750mm

|

900*900*780

900*900*930

900*900*1080

|

1

2

3

|

|

DY-1000-1S

DY-1000-2S

DY-1000-3S

|

1.1 kw

|

950mm

|

1160*1160*880

1160*1160*1030

1160*1160*1180

|

1

2

3

|

|

DY-1200-1S

DY-1200-2S

DY-1200-3S

|

1.5 kw

|

1150 mm

|

1360*1360*980

1360*1360*1160

1360*1360*1360

|

1

2

3

|

|

DY-1500-1S

DY-1500-2S

DY-1500-3S

|

2.2 kw

|

1450mm

|

1850*1850*1130

1850*1850*1330

1850*1850*1550

|

1

2

3

|

|

DY-1800-1S

DY-1800-2S

DY-1800-3S

|

3 kw

|

1750mm

|

2200*2200*1360

2200*2200*1460

2200*2200*1680

|

1

2

3

|

Customer Case

Payment & Shippment

Company Introduction

Dayong Vibration Equipment Co., Ltd is located in Xinxiang City--the hometown of China's vibrating screen. It is a professional manufacturer of screening and conveying equipment. Our company is specialty in the development and sales of vibration machinery, screening equipment, conveying equipment and lifting equipment. Our company produces a series of products as follows: round separator, screw conveyor, ultrasonic round separator, rectangular separator, vibration table, drum screen, SS 304 laboratory sieving machine test sieves, straight line vibrating screen, vibration motor, vibrating conveyor, feeding machine, hoisting equipment, belt conveyor. All of our production are widely used in food, pharmaceutical, chemical, metallurgy, building materials, mining, thermoelectric, environmental protection and other fields. And our company's business covers all parts of the country, and is exported to the United States, France, Canada, Russia, Australia, Japan, Singapore, Malaysia, India, Vietnam and other countries.

FAQ

Q: What information do I need to provide for getting an accurate quotation for SS 304 laboratory sieving machine test sieves?

1. Material’s name, bulk density, and water content

2. Capacity you required___kg/h

3. How many layers do you need?

4. The mesh size for each layer

5. Voltage and frequency

Q: How long for the delivery time?

A: 5-10 working days for conventional products.

Q: How long for warranty time?

A: 12 months from the shipping date.

Q: Can your engineer come to the construction site to guide the installation?

A: Yes, we can arrange our engineer to guide your installation, and salary is 150USD per day for one person, the air ticket/ visa/ local accommodation/ local traffic is in charge of customer.

Generally there is no need to send our engineer to guide, because we will provide detailed installation drawings to the customer, the customer only need to find special installation team to execute.

Best Selling

Hot Searches