- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dowell3D

-

Application:

-

3D PRINTING

-

Features:

-

Large build volume

-

Dimension(L*W*H):

-

printing size 900*900*1000mm

-

Voltage:

-

110v/220v

-

Weight:

-

350 KG

-

Core Components:

-

Other

-

Product name:

-

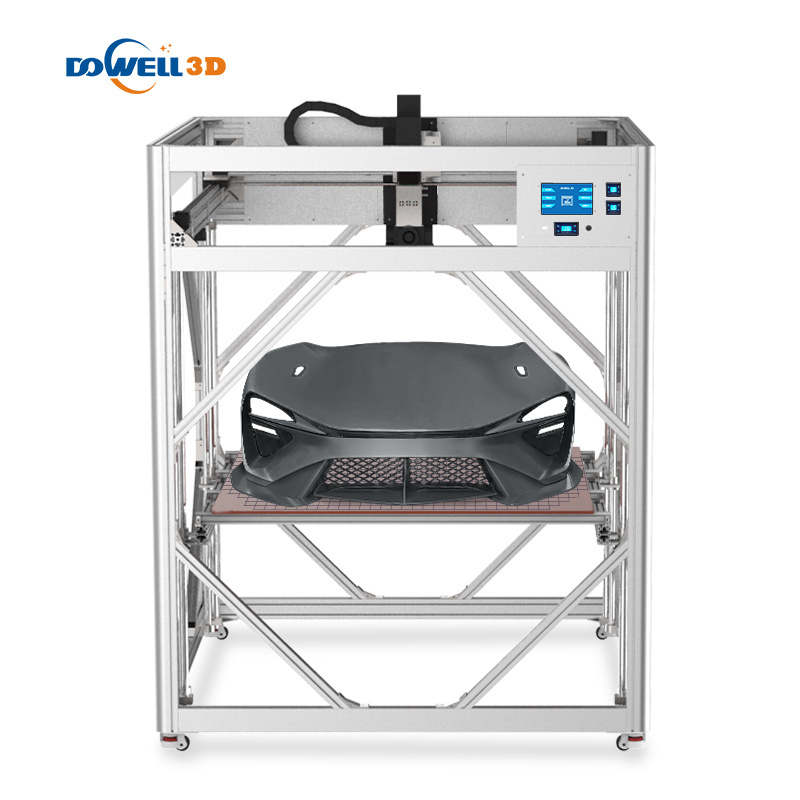

Dowell3d Pellet 3d printer

-

Support material:

-

Pellet 4mm

-

Nozzle diameter:

-

1.0/2.0/3.0mm

-

Printing size:

-

900*900*1000mm

-

Connectivity:

-

USB/SD Card

-

Software:

-

Cura/Dowell3D/Simplify3D

-

Plate Type:

-

Glass heating bed 0-100°c

-

Operating System:

-

Dowell /Klipper

-

After Warranty Service:

-

12 months

-

Nozzle temperature:

-

0-420°c

Quick Details

-

Production Capacity:

-

100%

-

Year:

-

2023

-

Forming size:

-

900*900*1000mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dowell3D

-

Application:

-

3D PRINTING

-

Features:

-

Large build volume

-

Dimension(L*W*H):

-

printing size 900*900*1000mm

-

Voltage:

-

110v/220v

-

Weight:

-

350 KG

-

Core Components:

-

Other

-

Product name:

-

Dowell3d Pellet 3d printer

-

Support material:

-

Pellet 4mm

-

Nozzle diameter:

-

1.0/2.0/3.0mm

-

Printing size:

-

900*900*1000mm

-

Connectivity:

-

USB/SD Card

-

Software:

-

Cura/Dowell3D/Simplify3D

-

Plate Type:

-

Glass heating bed 0-100°c

-

Operating System:

-

Dowell /Klipper

-

After Warranty Service:

-

12 months

-

Nozzle temperature:

-

0-420°c

Products Description

|

Model:

|

DP Series

|

|

|

|

|||

|

Printing area:

|

900*900*1000MM--1500*2300*1600mm

|

|

|

|

|||

|

Extruder:

|

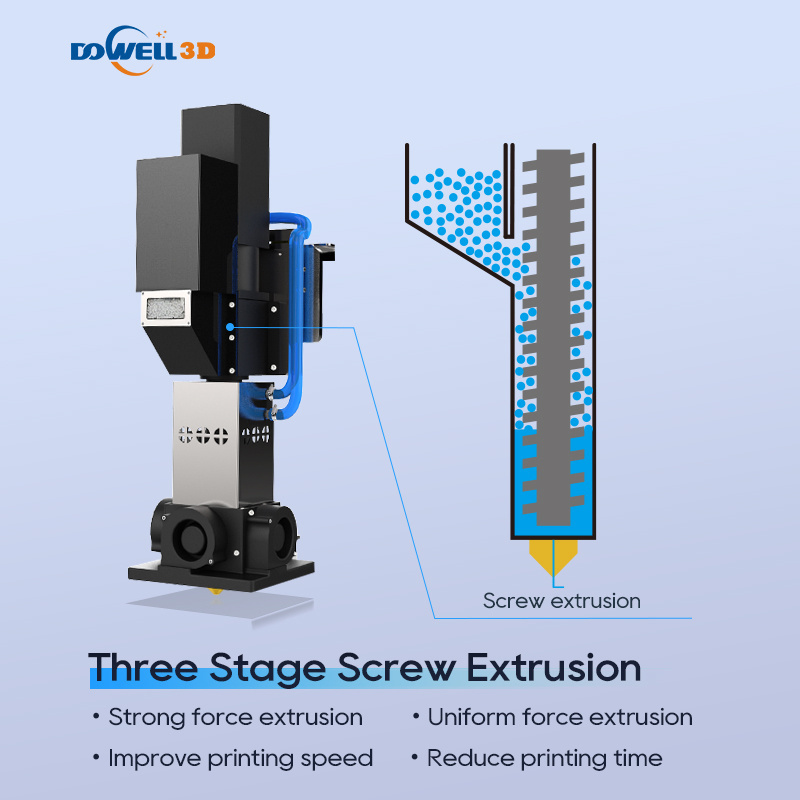

Single screw extrusion

|

|

|

|

|||

|

Nozzle temperature:

|

0-420℃

|

|

|

|

|||

|

Heating platform:

|

6mm tempered glass 0-100℃ (150°c customization)

|

|

|

|

|||

|

Leveling:

|

auto leveling, auto 64 points level

|

|

|

|

|||

|

Screen size:

|

Full color touch screen

|

|

|

|

|||

|

Voltage:

|

110V/220V

|

|

|

|

|||

|

File format:

|

STL/OBJ/STP/Gcode

|

|

|

|

|||

|

Pellet diameter:

|

<4mm

|

|

|

|

|||

|

Connectivity:

|

USB, SD Card, Wifi customizable.

|

|

|

|

|||

|

Control system:

|

3 stage temperature control, liquid cooling.

|

|

|

|

|||

|

Standard Characteristic

|

auto leveling, auto resume from power off, auto power off

|

|

|

|

|||

|

Customization options:

|

Printing volume / Klipper System / Constant temperature enclosure

|

|

|

|

|||

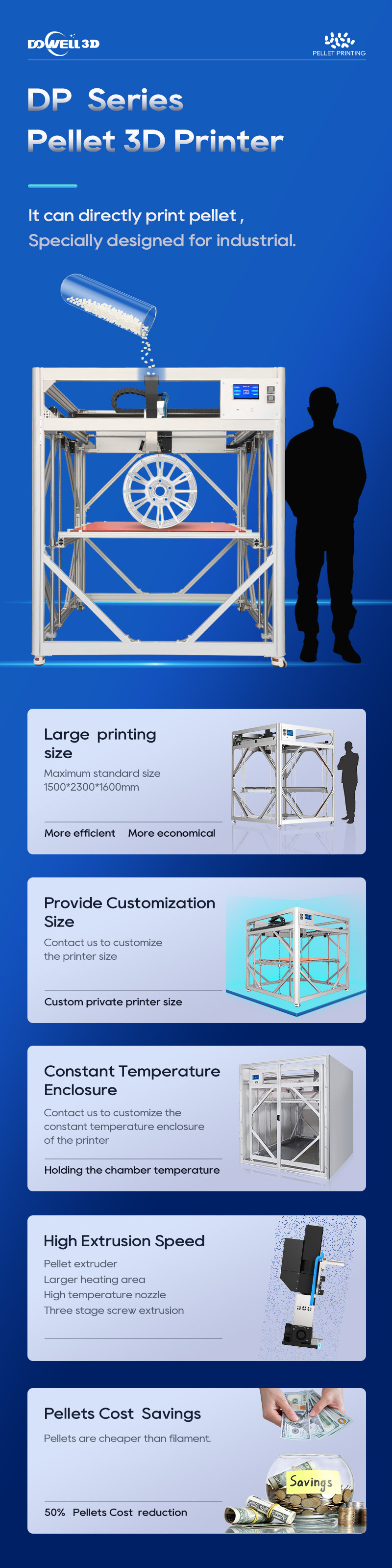

Why Dowell 3D Pellet Printer

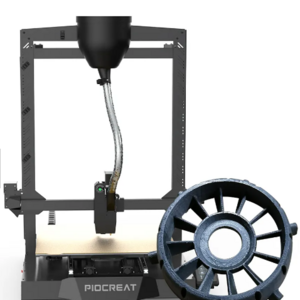

Dowell 3d printer converts raw material directly to the print bed in a granular form.

It is designed to print big projects, resulting in shorter turnaround times and more reliability with low material cost, fast printing speed and the final product is with high strength.

1. Pellet extruder to print pellet directly, lower cost.

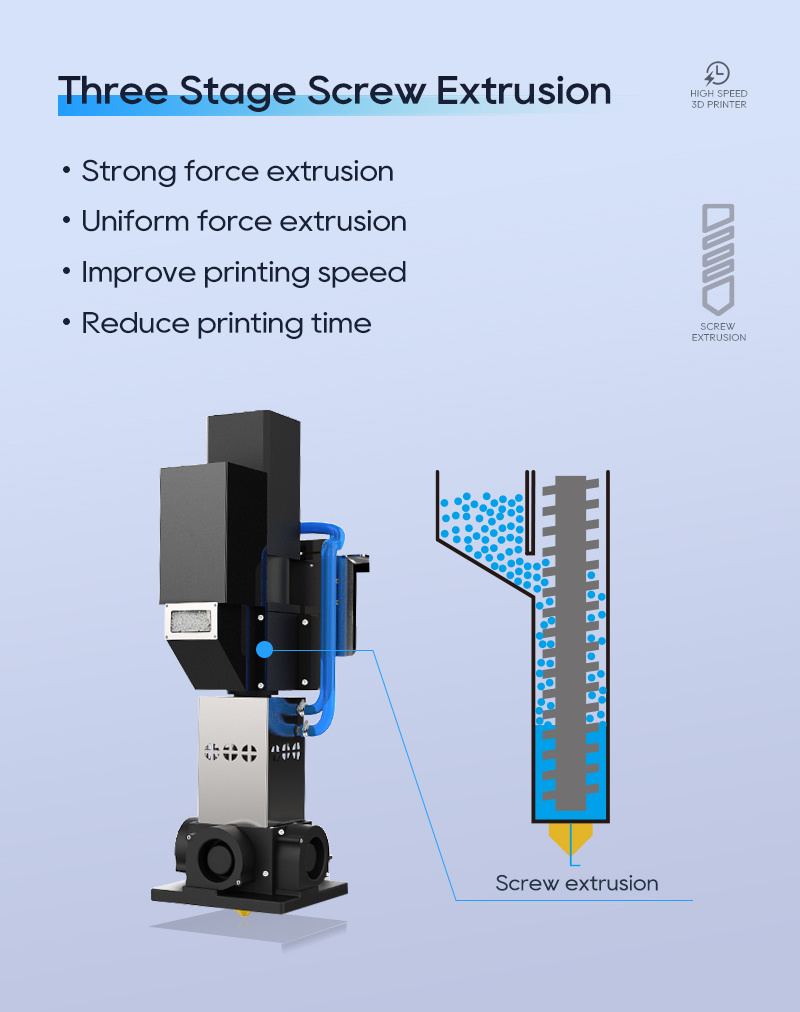

2. Screw feeding,

3 stages temperature control.

3. Water cooling system.

4. 3D/BL touch 64 points auto leveling.

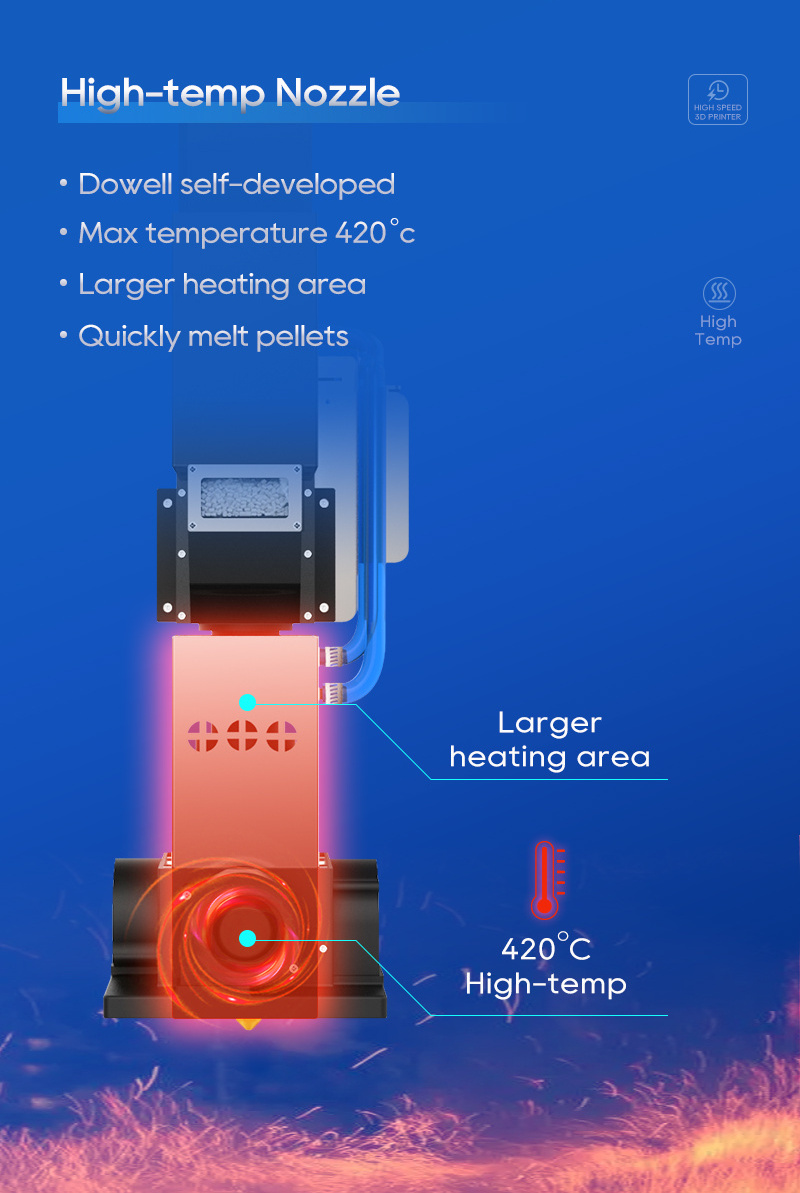

5. 420C high temperature nozzle.

6. 100C high temperature hot bed (optional 150C).

7. Variety of large size model, accept customize.

8. Optional max 60C constant temperature enclosure.

4. 3D/BL touch 64 points auto leveling.

5. 420C high temperature nozzle.

6. 100C high temperature hot bed (optional 150C).

7. Variety of large size model, accept customize.

8. Optional max 60C constant temperature enclosure.

Material save

Pellets are the raw form of most plastics used in industrial molding processes such as injection molding, and therefore cost up to 10 times less than traditional 3D printing filament feedstock. Overall, pellets are considered one of the lowest-cost 3D printing raw materials.

High temperature Extruder

420C high temperature nozzle,

support a variety of material availability.

3 Stage High performance screw extrusion

Powerful extrusion force. Precise 3 stage independent temperature control, making extrusion even and smooth.

Water cooling system,

Precise temperature control ensures printing quality

Rapid heat dissipation, cooling water circulates through it, absorbing the heat of the extruder. The warmer water returns from the hot end, is cooled by the radiator, and then circulates back to the hot end, keeping the material solid so it can be pushed by the extruder before entering the "melt zone" and turning into a liquid.

Reduce noise

Dowell uses an independently developed low-noise motor, which will not affect your life and rest when doing a long print jobs.

Auto resume from power recovery

It saves the print job status and if the power outage occurs, Dowell printers provide the option to resume interrupted print jobs.

High temperature hot bed

The whole platform is heated by silicon rubber heater evenly, temp controlled by independent controller. Standard max temp 100C, optional 150C.

Auto Leveling

First perform 4 corner detection, then 64-point detection, automatically adjust for unevenness.

Customization options

Customization printing size

We supply 14 standard sizes, if there is no size that can meet your printing needs, please contact us to customize it for you.

Constant 60°c temperature enclosure

The Standard pellet printer is open frame, we also provide an option of 0- 60C constant temperature enclosure. There is independent heaters and temperature control system.

Klipper system

Support wifi connection for remote control,

Real-time adjustment of Z off-set, acceleration, and enjoy the free software upgrade service provided by Dowell.

User's Feedback

Hot Searches