- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HYRD

-

material:

-

alumina

-

acid resistance:

-

good

-

refractoriness:

-

high

-

permeability resistance:

-

excellent

-

thermal shock resistance:

-

good

-

bulk density:

-

1.9-2.5 g/cm3

-

usage:

-

easy

-

color:

-

white

-

price:

-

reasonable

-

OEM:

-

yes

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Liaoning, China

-

Model Number:

-

Customer's Requirements

-

Brand Name:

-

HYRD

-

material:

-

alumina

-

acid resistance:

-

good

-

refractoriness:

-

high

-

permeability resistance:

-

excellent

-

thermal shock resistance:

-

good

-

bulk density:

-

1.9-2.5 g/cm3

-

usage:

-

easy

-

color:

-

white

-

price:

-

reasonable

-

OEM:

-

yes

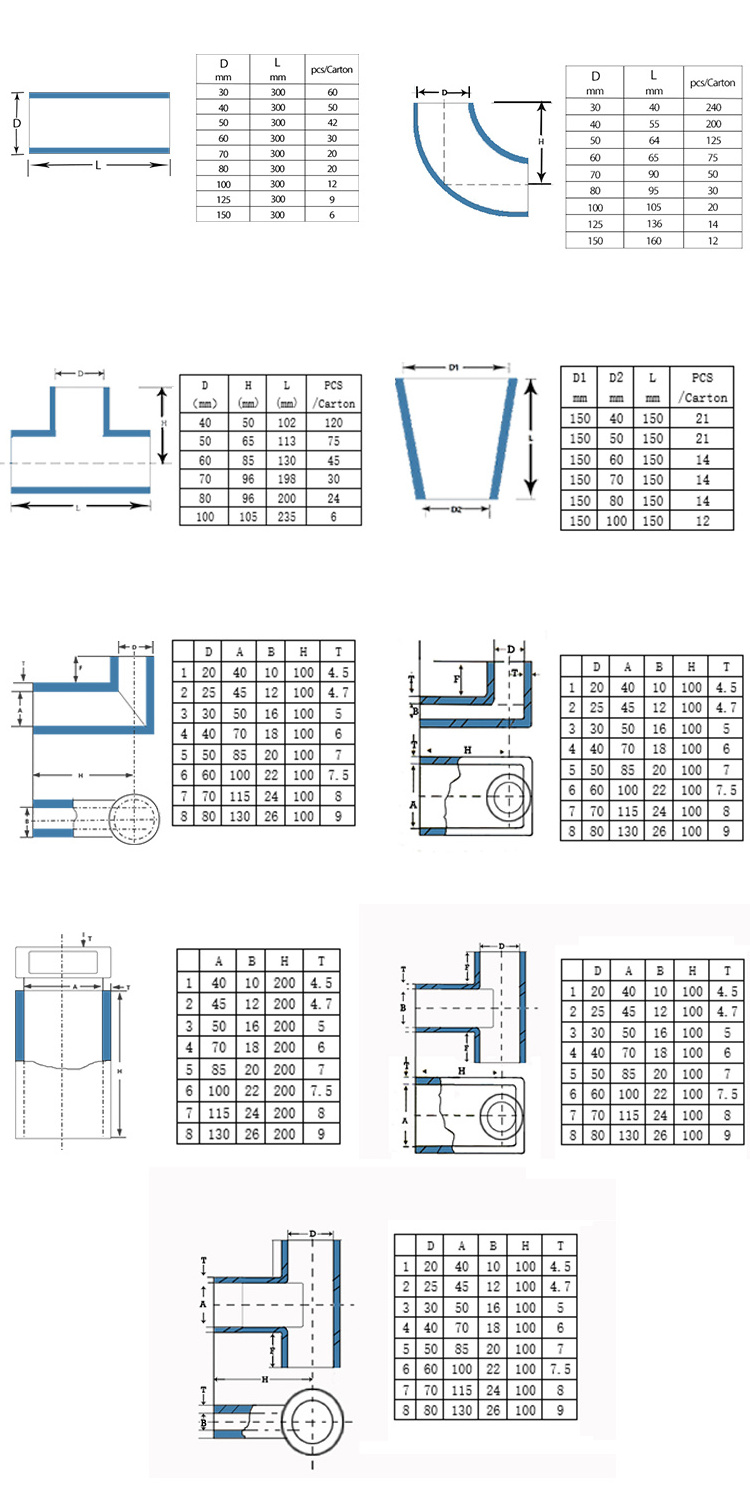

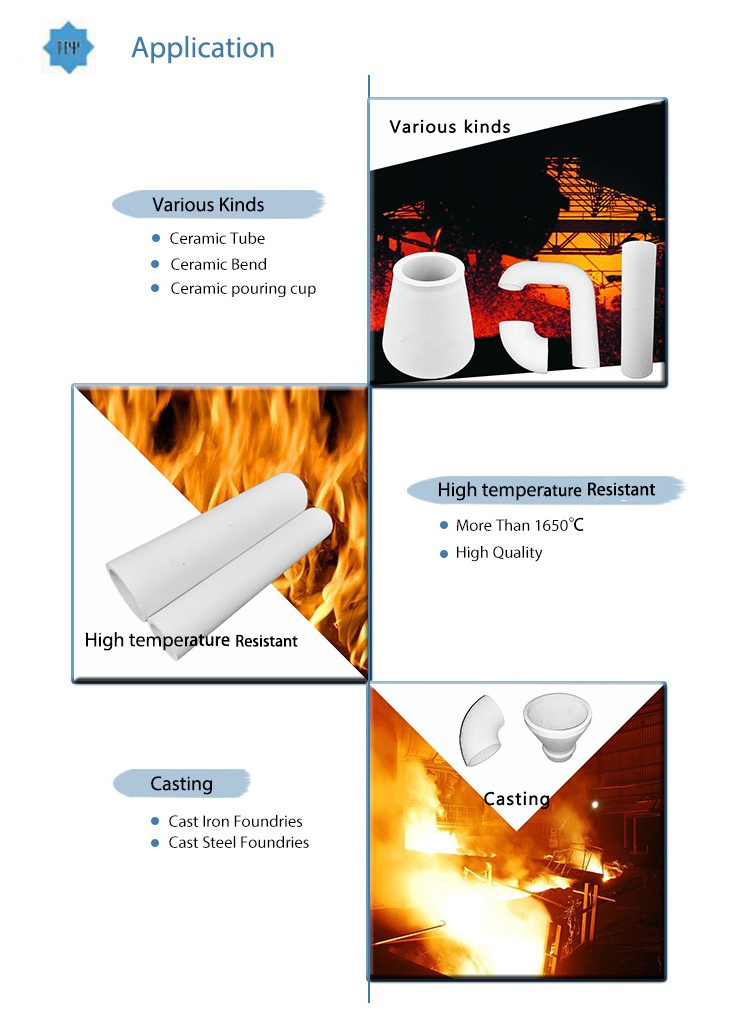

High Working Temperature Mullite Alumina Ceramic Tube for Gating System

Good Quality Alumina Ceramic Tube in Stock

is refractory consumables used for gating system(running system) during casting, which includes funnels, tubes, bends, tees, etc. as seen from following photos.

They are widely used for casts of tens of KG to hundred tons in cast steel and cast iron foundries, which could effectively

improve cast quality, and highly recognised by various foundries.

They are widely used for casts of tens of KG to hundred tons in cast steel and cast iron foundries, which could effectively

improve cast quality, and highly recognised by various foundries.

The features of products

•Lighter stronger and easy to assemble

•Smooth internal surface promoting streamlined flow and reduce contaminant pick-up.

•Accurate and consistent dimensions.

•Reduce casting defects of sand holes, sand-flushing, and sand inclusions.

•Metal erosion resistance much better than traditional refractories .

•Good thermal shock resistance

•Higher working temperature

|

Technical parameters

|

|

|

|

|

||||

|

Bulk density

kg/cm3

|

Cold compressive

strenght

MPa

|

Thermal expansivity

1000°C K-1 |

Thermal conductivity

600°C W/m.k |

Working temperature

°C |

||||

|

>1.9

|

>15

|

1.65*10-6

|

0.76

|

1650

|

||||

|

Chemical composition

|

|

|

|

|

||||

|

Al2O3

|

SiO2

|

Fe2O3

|

CaO

|

other

|

||||

|

>60%

|

<35%

|

<1.5%

|

<1.7%

|

<2%

|

||||

Hot Searches