- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XingDian

-

Voltage:

-

110V/220V/380V

-

Weight:

-

36000 kg

-

Marketing Type:

-

New Product 2023

Quick Details

-

Production Capacity:

-

1000pcs/h

-

Product Type:

-

New egg tray machine

-

Processing Type:

-

egg carton molding machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XingDian

-

Voltage:

-

110V/220V/380V

-

Weight:

-

36000 kg

-

Marketing Type:

-

New Product 2023

Product Overview

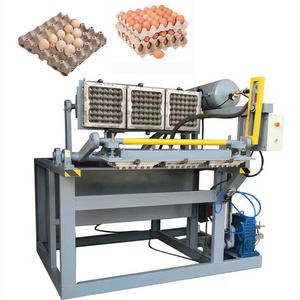

Egg Tray Egg Carton Making Machine

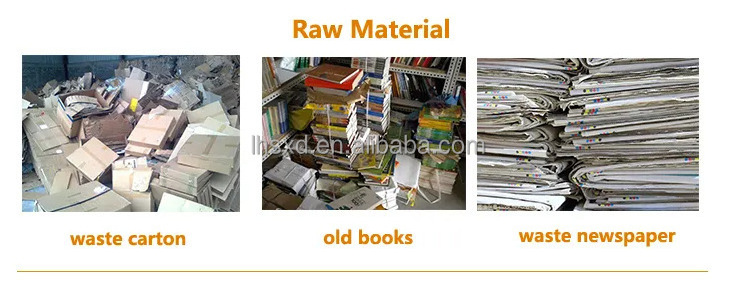

Our egg tray machine and molding mould are fully designed by computer-assistant engineering and high technology. The pulp molding system can use all kinds of waste paper to produce high quality molded fibre products. Such as egg trays, egg cartons, fruit trays, strawberry punnets, red wine trays, shoe trays, medical trays and seed germination trays, etc.

FEATURES AT A GLANCE

Paper egg tray machine is used to process raw waste paper into egg trays/cardboard boxes/boxes, bottle racks, fruit trays, shoe covers, etc. The entire production is completed by one production line. On this production line, their hosts come in three types: reciprocating, drum, and rotary, with different working methods. Usually, rotary machines have a larger capacity.

Working process of egg tray machine:

The waste paper is added to the pulp crusher and transported to the storage tank with water. The pulp from the storage tank is stirred evenly by a mixer and transported to the pulp supply tank. The pulp from the supply tank is stirred to a certain concentration and transported to the forming machine. The forming machine produces egg trays and the conveyor belt passes through a drying hole to dry the egg trays. Finally, the trays are collected and packaged. In addition, the unused water in the molding machine can be pumped to the return water tank through a vacuum pump, which can transport water to the pulp crusher and storage tank, achieving water circulation and utilization

The equipment has a production capacity of 1000-7000 pieces per hour, which can be freely selected

PRODUCT SPECIFICATIONS

|

Machine Model

|

1*3

|

1*4

|

3*4

|

4*4

|

4*8

|

5*8

|

5*12

|

|

Yield(p/h)

|

1000

|

1500

|

2000

|

2500

|

4000

|

5000

|

6000

|

|

Waste Paper(kg/h)

|

120

|

160

|

200

|

280

|

320

|

400

|

480

|

|

Water(kg/h)

|

300

|

380

|

450

|

560

|

650

|

750

|

900

|

|

Electricity(kw/h)

|

32

|

45

|

58

|

78

|

80

|

85

|

90

|

|

Workshop Area

|

45

|

80

|

80

|

100

|

100

|

140

|

180

|

|

Drying Area

|

No need

|

216

|

216

|

216

|

216

|

238

|

260

|

Packing and shipping:

Company information:

Our services:

1) Highly inspecting equipments in every working procedure, quality comes first; Fast & Safe Delivery;

2) Assisting our clients for foundation construction of equipment;

3) Dispatching engineers to install and debug equipment;

4) Training the first-line operators on site;

5) Regularly visit clients to solve production problems;

6) Providing life-long maintenance service;

7)Providing technical exchanging;

2) Assisting our clients for foundation construction of equipment;

3) Dispatching engineers to install and debug equipment;

4) Training the first-line operators on site;

5) Regularly visit clients to solve production problems;

6) Providing life-long maintenance service;

7)Providing technical exchanging;

FAQ:

Hot Searches