- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

30

-

Weight (KG):

-

150 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SUNRISE

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1200*450*1050 mm

-

Power (kW):

-

0.75 kW

-

Item:

-

dry powder mixer

-

Capacity:

-

50-2000 L

-

Usage:

-

Mixing powder

-

Function:

-

Blending

-

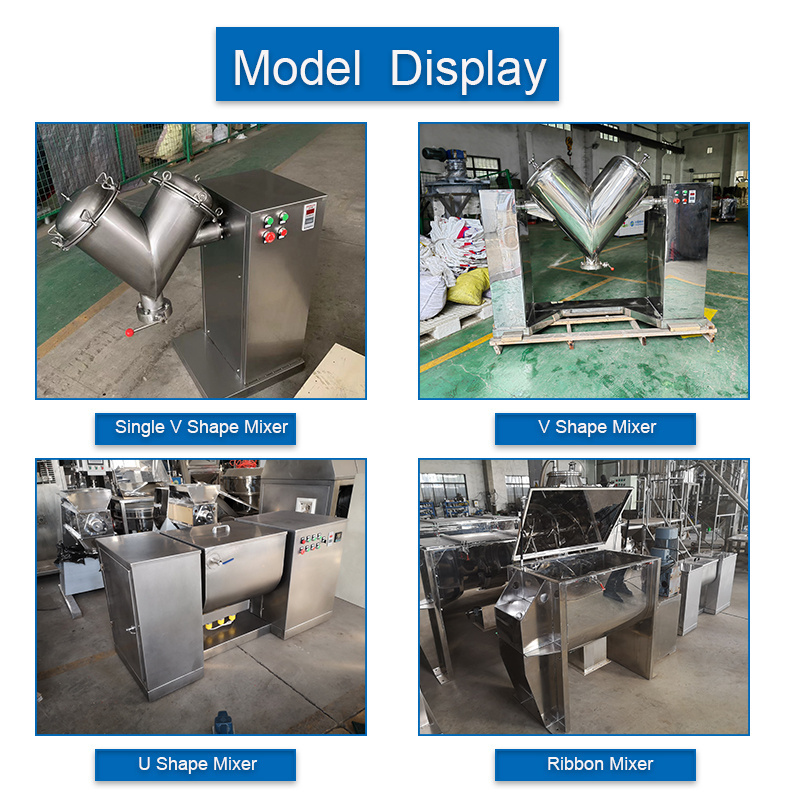

Type:

-

V shape or U shape

-

Processing material:

-

dry powder

-

Mixing time:

-

10-20 minutes

-

Speed:

-

24 RPM can be adjustable

Quick Details

-

Barrel Volume (L):

-

50

-

Max. Loading Volume (L):

-

30 L

-

Range of Spindle Speed(r.p.m):

-

1 - 12 r.p.m

-

Max. Loading Capacity:

-

30

-

Weight (KG):

-

150 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SUNRISE

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1200*450*1050 mm

-

Power (kW):

-

0.75 kW

-

Item:

-

dry powder mixer

-

Capacity:

-

50-2000 L

-

Usage:

-

Mixing powder

-

Function:

-

Blending

-

Type:

-

V shape or U shape

-

Processing material:

-

dry powder

-

Mixing time:

-

10-20 minutes

-

Speed:

-

24 RPM can be adjustable

Product Details

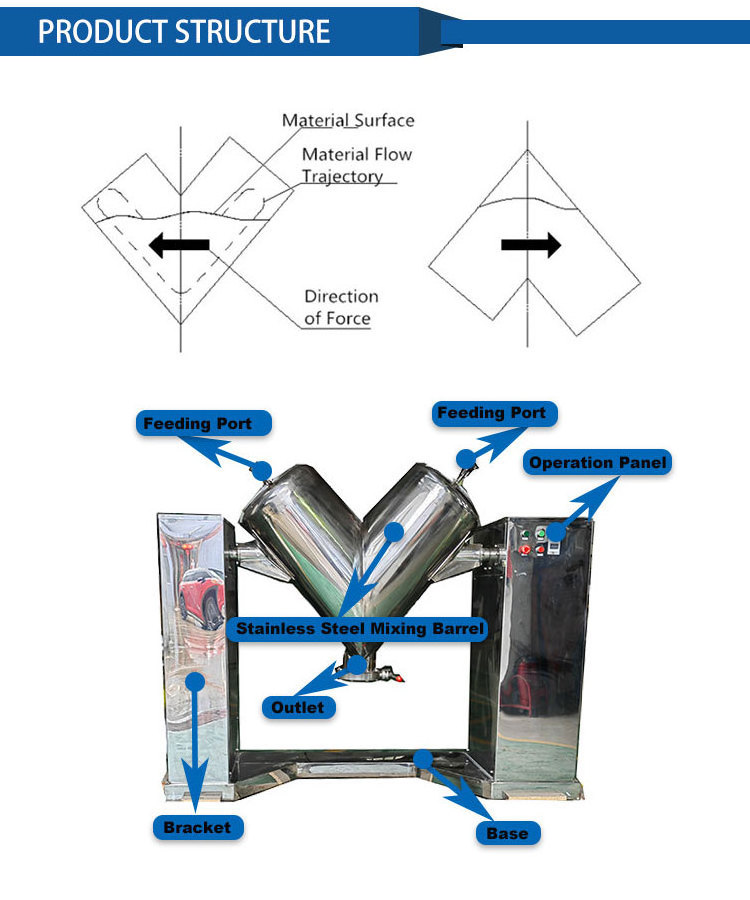

V-Type Powder Mixer

V-Type Powder Mixer Machine

is designed for mixing two or more dry and power or granule raw materials from che industry,foodstuff industry and so on.

The structure of

V-Type Powder Mixer

in unique. Its mixing efficiency is high and no dead corner .It is made of stainless steel. Its inner and outer wall is processed through polishing. Its appearance is beauty. Its mixing is uniform.

Its scope of application is wide.The forced stirrer can also be equipped, according to request of client, to meet the requirements of raw materials that contain pretty fine powder.cake and certain moist stuff.

Full Automatic V-Type Dry Powder Mixer

V-type mixer is suitable for food and other industries.

Mixing of dry powder and granular material with better flowability.

V-Type Powder Mixer

Working Principle

V-type powder mixer

equipment uses two cylinders of the mixer with different lengths and asymmetrical rows. When the mixer rotates, the materials are decomposed into combinations, from combinations to decomposition. Due to the different material planes, there are also transverse forces, which promote the material to exchange horizontally. Each turn of transverse force makes about 25% of the material flow from one barrel to another, so that the material mixes horizontally and radially,and the decomposition combination proceeds with each other, so that the material can achieve a very uniform mixing effect.

V-type mixer is a common powder and granular material mixer in the world. The utility model has the advantages

of simple structure, easy operation,convenient maintenance and cleaning, fast speed and good mixing effect.

Technical Data

|

Item

|

V-type mixer

|

V-type mixer

|

V-type mixer

|

|

Model

|

VM-50

|

VM-200

|

VM-1000

|

|

Barrel volume

|

50

|

200

|

1000

|

|

Loading

volume

|

20-30 L

|

100-120 L

|

500-600L

|

|

Motor powder

|

0.75 KW

|

1.1KW

|

4KW

|

|

Mixing speed

|

15

|

12

|

10

|

|

Mixing time

|

5-10 min

|

10-20min

|

20-30min

|

|

Dimension( m)

|

1.25*0.45*1.05

|

1.*0.6*1.7

|

2.9*0.72*2.1

|

|

Weight

|

200 KG

|

335 KG

|

700 KG

|

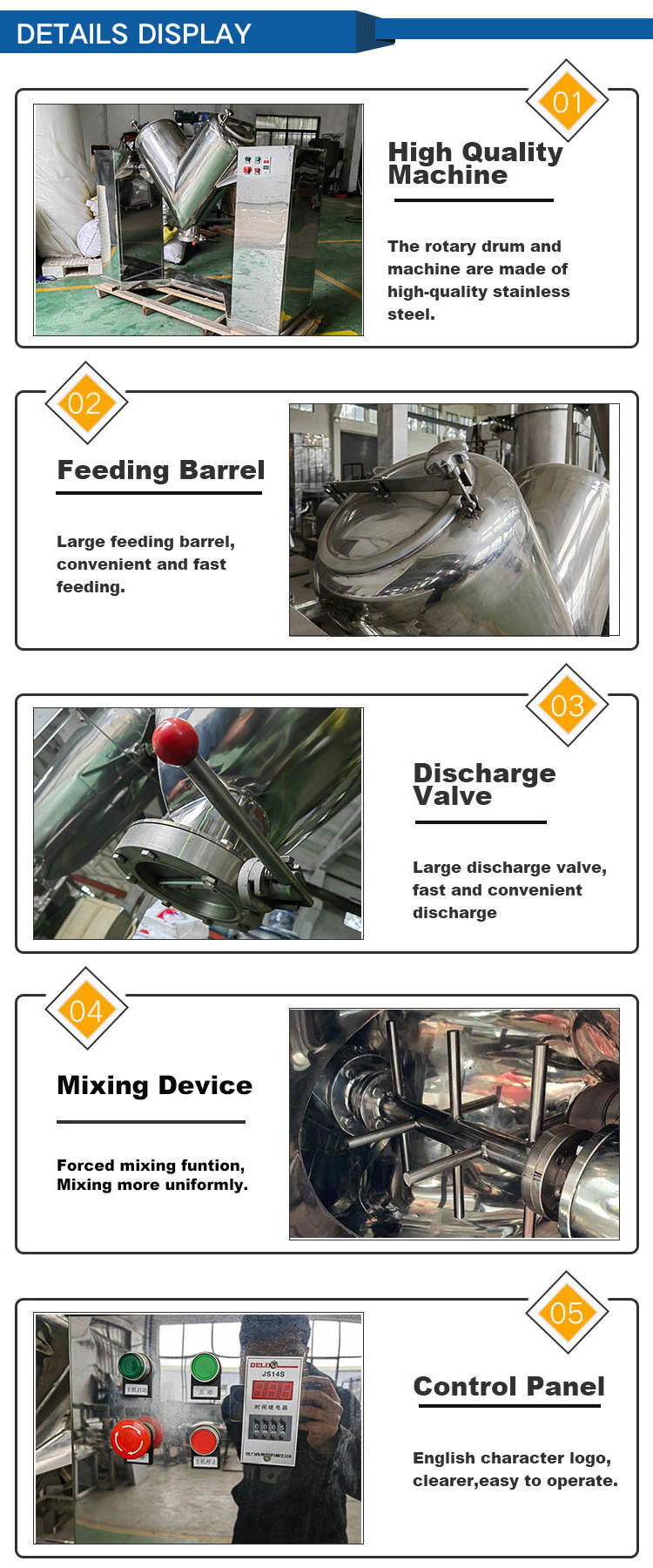

Advantages

①Multi-dimensional space movement can make the material fully mixed and uniform macroscopically

②No centrifugal force during mixing.

③Free of dead corner.

Disadvantages

①Microscopically, it is not easy to achieve refined mixing.

②It is not easy to make large equipment with more than 1000 liters.

Advantages

①No dead corners of materials during mixing.

②When the mixed powder has good fluidity and similar physical properties, a better mixing effect can be obtained.

Disadvantages

①Microscopically, the powder is not easy to mix well.

②Ultra-fine powder and ultra-light powder are not easy to mix into the main powder.

③There is a throwing motion, which will destroy the shape of the powder.

Advantages

①The dual cone cylinder adapts to the mixing requirements of the mixed materials without dead angles.

②The gentle running speed will not cause damage to fragile materials.

③It can meet the production of large batches of batch mixing.

Disadvantages

①If the bucket is fixed, there will be dead corners of the material.

②There are residues in the discharge.

Advantages

①Large loading factor, small occupied area.

②There are shearing blades inside to achieve uniform mixing at the microscopic level.

Disadvantages

①If the bucket is fixed, there will be dead corners of the material.

②There are residues in the discharge.

Q1: What power do you use in your factory?-V,-Hz, 3 phase or single phase?

(Like 220 V , 50 Hz , single or 380 V, 50 Hz ,3 phase...etc)

Q2: Can I Put my Logo on the machine?

Yes, Sure .

Q3. How can I trust you for the first-time business?

We can supply the business license and certificates. if you still worry about our company,

Q2: Can I Put my Logo on the machine?

Yes, Sure .

Q3. How can I trust you for the first-time business?

We can supply the business license and certificates. if you still worry about our company,

we suggest using Alibaba trade assurance service for all transactions to protect your money

and ensure our service for you.

Q4. How can you ensure the machine's quality after we purchase the order?

Before delivery, we will produce the equipment according to the agreed requirements, and

Q4. How can you ensure the machine's quality after we purchase the order?

Before delivery, we will produce the equipment according to the agreed requirements, and

after production, we will provide detailed operating instructions, testing videos, certification

documents, etc. Alternatively, you can arrange a third-party inspector to do inspection and

give you report.

Q5: How about the after-sale service and guarantee period?

1. 18-month warranty period for whole machine except for human factors etc. and 18 months’

1. 18-month warranty period for whole machine except for human factors etc. and 18 months’

after-sale service starts from the date when you receive machine .

2. Consultation services for whole machine life, and 24 hours technical support by email or video on line.

3.English software, user manual and the installation & debugging by our experienced technicians.

2. Consultation services for whole machine life, and 24 hours technical support by email or video on line.

3.English software, user manual and the installation & debugging by our experienced technicians.

Hot Searches