- Product Details

- {{item.text}}

Quick Details

-

Feature:

-

Moisture Proof

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

DADAO

-

Model Number:

-

DD-MPF3

-

film:

-

matte,glossy

-

thickness:

-

10mic-350mic ect.

-

Materials:

-

100mic PET +25mic EVA other thickness accept customized

Quick Details

-

Material:

-

PET

-

Type:

-

Stretch Film

-

Usage:

-

Packaging Film

-

Feature:

-

Moisture Proof

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

DADAO

-

Model Number:

-

DD-MPF3

-

film:

-

matte,glossy

-

thickness:

-

10mic-350mic ect.

-

Materials:

-

100mic PET +25mic EVA other thickness accept customized

Product Description

125mic PET+EVA Thermal Pouch Film/Laminating Pouches A4 Size

PET precoated film refers to the process of laminating and rewinding PET film in advance and then combining it with paper printing.Coating film, it is to point to be coated on plastic film adhesive, with paper printed matter after heating, pressure to make its agglutinate together, form the processing technology of paper plastic products.

Thermal Laminated printing, due to the surface of the thin and transparent of PET Transparent film, the surface is more smooth, bright, so improve the print gloss and fastness, text color is brighter, full of three-dimensional sense, at the same time more waterproof, antifouling, wear-resisting, folding, chemical corrosion and other effects

Feature:

1.The thickness of should be between 0.01 and 0.2mm, and the surface tension reach 4.0 x 10-2n /m after corona treatment or other treatment, so as to have better wetting performance and bonding performance.

2.The corona treatment surface treatment effect uniform, the transparency of the higher the better, to ensure that the covered print has the best clarity.

3.With good light resistance, under the light for a long time not easy to change color, the geometric size remains stable.

4.Has a certain chemical stability.

5.Appearance should be flat, no uneven and wrinkles, no bubbles, shrinkage and pitting and other defects.

Technical Data Sheet

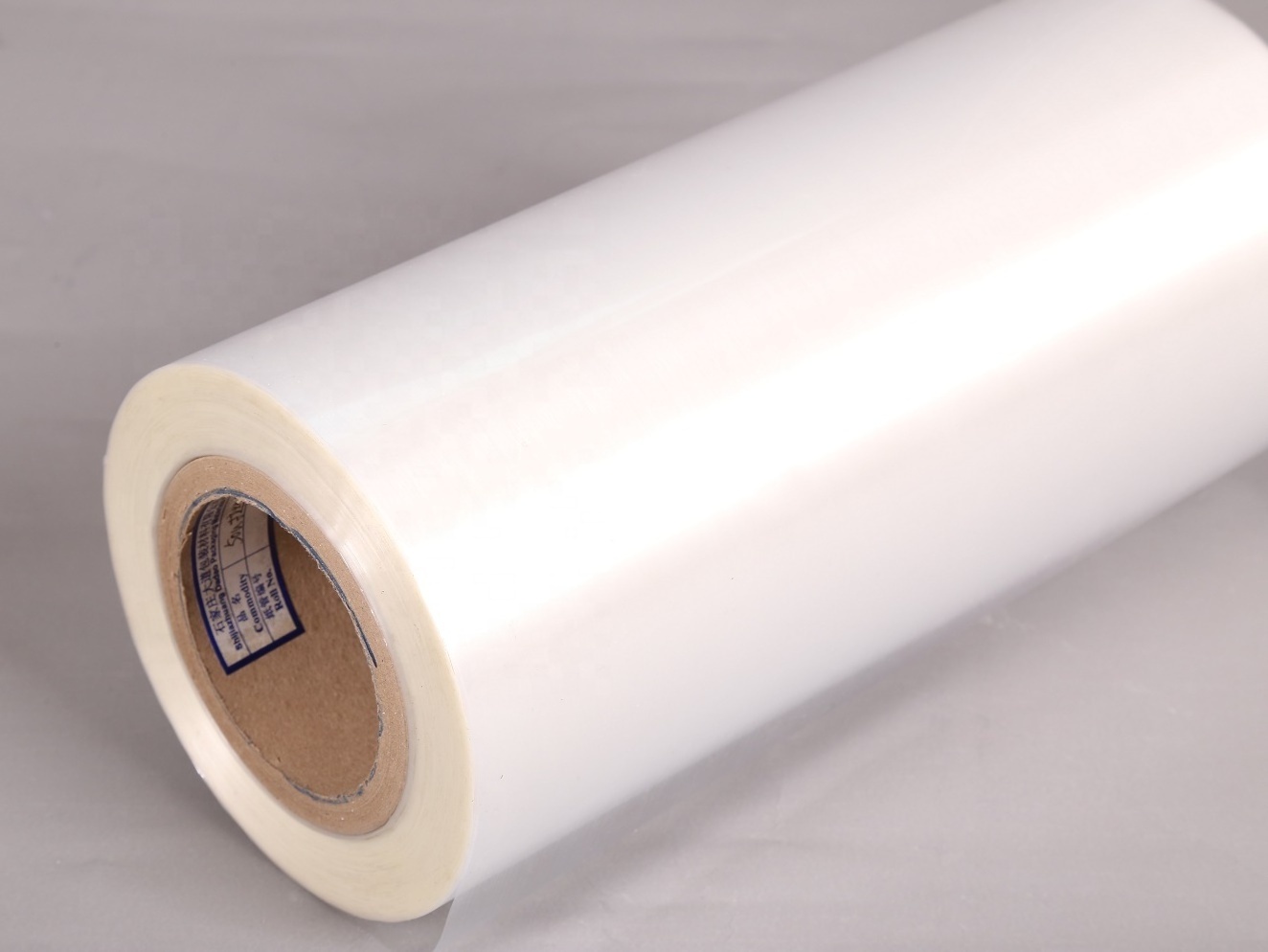

Type: Glossy/matte transparent pet thermal lamination film

Gold metallized bopet thermal lamination film

Silver metallized bopet thermal lamination film

Brushed metallized/transparent bopet thermal lamination film (Accept customized)

Thickness:12 -250 micron( Accept customized)

Width: ≤2100mm

Color:Silver and Gold is normal color , accept other colors customized

Paper core ID: 3 “ 76mm,6”152mm

|

Item

|

|

Unit

|

Index

|

Test method

|

|

|

Thickness of based film

|

|

μm

|

12±5

|

ASTM D-374

|

|

|

Thickness of gule film

|

|

μm

|

15±5

|

ASTM D-374

|

|

|

Tensile strength

|

MD

|

Mpa

|

≧220

|

ASTM D-882

|

|

|

|

TD

|

|

≧250

|

|

|

|

Elongation at

Break |

MD

|

%

|

≧110

|

ASTM D-882

|

|

|

|

TD

|

|

≧100

|

|

|

|

Shrinkage (150℃,30min )

|

MD

|

%

|

<MD 2.0

|

ASTM D-1204

|

|

|

|

TD

|

|

<TD 1.5

|

|

|

|

Wetting tension

|

Metal side

|

Mn/m

|

≧42

|

ASTM D-2578

|

|

|

Moisture transmittance

|

|

g/(㎡.24h)

|

≤2.0

|

ASTM F1249

|

|

|

Oxygen transmittance

|

|

cm³/(㎡.24h.0.1Mpa)

|

≤50

|

ASTM F1927

|

|

|

Reflectivity

|

|

%

|

≧50

|

ASTM D1003

|

|

|

welding strength

|

|

N

|

>7

|

ASTM F88

|

|

|

Heat sealing temperature

|

|

℃

|

>125

|

ASTM D648

|

|

|

Adhesion of Aluminum Layer

|

|

%

|

No Al layer peels

|

3M tape

|

|

|

Uniformity of aluminum layer

|

|

%

|

9

|

GB/T-15717

|

|

|

Violence, streaks

|

|

/

|

No

|

visual inspection

|

|

Details Images

Product packaging

Hot Searches