- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

36000 KG

-

Raw material:

-

Waste Tyre Rubber Plastic

-

Final product:

-

Fuel Oil Steel Carbon Back

-

Machine Name:

-

Used Rubber Pyrolysis Oil Machine

-

Function:

-

Extract Oil

-

Reactor life:

-

5~8 Years

-

Cooling method:

-

Water Recycling Cooling

-

Reactor Thickness:

-

16MM/18MM

-

Work Pressure:

-

Normal Pressure

-

Power:

-

20KW

-

Feature:

-

Environment Friendly

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

mingsen

-

Equipment Capacity:

-

15

-

Weight (KG):

-

36000 KG

-

Raw material:

-

Waste Tyre Rubber Plastic

-

Final product:

-

Fuel Oil Steel Carbon Back

-

Machine Name:

-

Used Rubber Pyrolysis Oil Machine

-

Function:

-

Extract Oil

-

Reactor life:

-

5~8 Years

-

Cooling method:

-

Water Recycling Cooling

-

Reactor Thickness:

-

16MM/18MM

-

Work Pressure:

-

Normal Pressure

-

Power:

-

20KW

-

Feature:

-

Environment Friendly

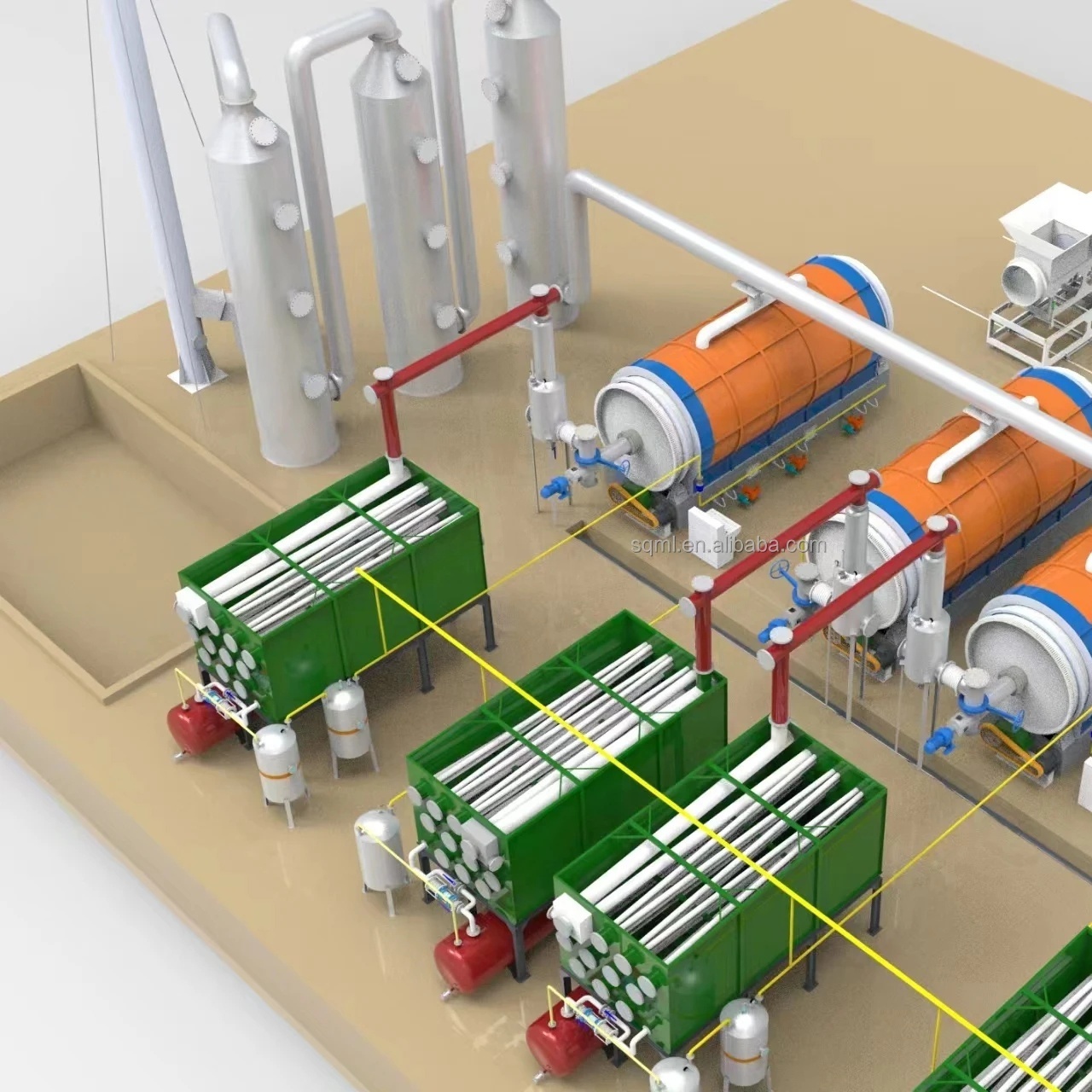

Products Description

Appliance Area

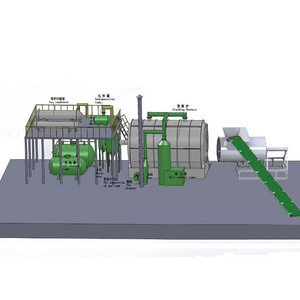

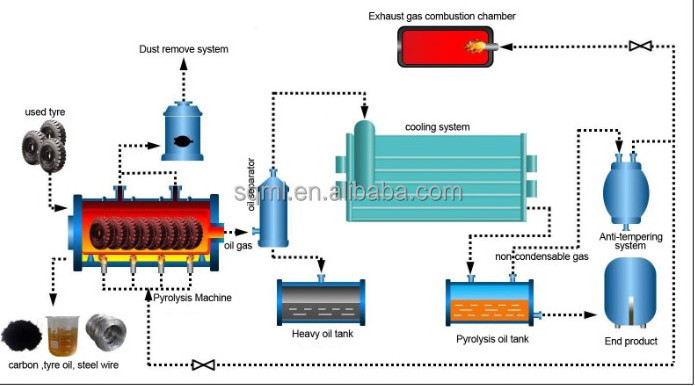

Working process of tire fuel oil plant:

First, the raw materials are put into the reactor, and then seal the feeding in door, later start the machine and the reactor will be rotating and heated by coal, natural gas, wood or electricity. When the temperature reaches the degree of 250 to 280, we will get the crude oil, the oil steam will be continuous produced until the temperature reaches 350-460°C; oil steam will flow through oil gas separator, light component will enter the condensers and meanwhile the heavy oil will be discharged automatically into in heavy oil tank. The liquefied part will be condensed as crude oil, and the part which cannot be liquefied will be transferred by the water seal back to the burning chamber to be reused as heating material

First, the raw materials are put into the reactor, and then seal the feeding in door, later start the machine and the reactor will be rotating and heated by coal, natural gas, wood or electricity. When the temperature reaches the degree of 250 to 280, we will get the crude oil, the oil steam will be continuous produced until the temperature reaches 350-460°C; oil steam will flow through oil gas separator, light component will enter the condensers and meanwhile the heavy oil will be discharged automatically into in heavy oil tank. The liquefied part will be condensed as crude oil, and the part which cannot be liquefied will be transferred by the water seal back to the burning chamber to be reused as heating material

Product Paramenters

|

Product Name

|

Tyre Pyrolysis Machine

|

|

|

|

|||

|

Capacity

|

2TPD, 5TPD ,6TPD 8TPD ,10TPD,12TPD,15TPD

|

|

|

|

|||

|

Reactor Materials

|

Q345R,Alloy Steel,Stainless Steel

|

|

|

|

|||

|

Reactor Thinckness

|

16.45mm, 18.50mm

|

|

|

|

|||

|

Total weight

|

30-40ton (Varies by Design and Capacity)

|

|

|

|

|||

|

Working power

|

15-35KW(Varies by Design and Capacity)

|

|

|

|

|||

|

Labor Qty Require

|

2-4 Person for per set machine,more machine ,fewer labors

|

|

|

|

|||

|

Processing Time

|

feeding 2Hours,processing 8-9 hours,Carbon black and steel wire Discharging 1.5hours( Take 12ton Capacity for example)

|

|

|

|

|||

|

Application Materials

|

Waste tyre,Waste rubber,Waste plastic ,waste oil sludge ,waste Aluminum foil,Waste cable ,waste leather ,waste Acrylic(PMMA), ect.....

|

|

|

|

|||

|

Heating fuel

|

pyrolysis oil ,Natural gas ,Electricity,Coal ,Firewood ect...

|

|

|

|

|||

Details Images

Feeding

This is the Auto feed ,to put the waste materials into reactor .

The Auto feeder not

only greatly save time and labors but also loading more tyres.

This device is our patent product

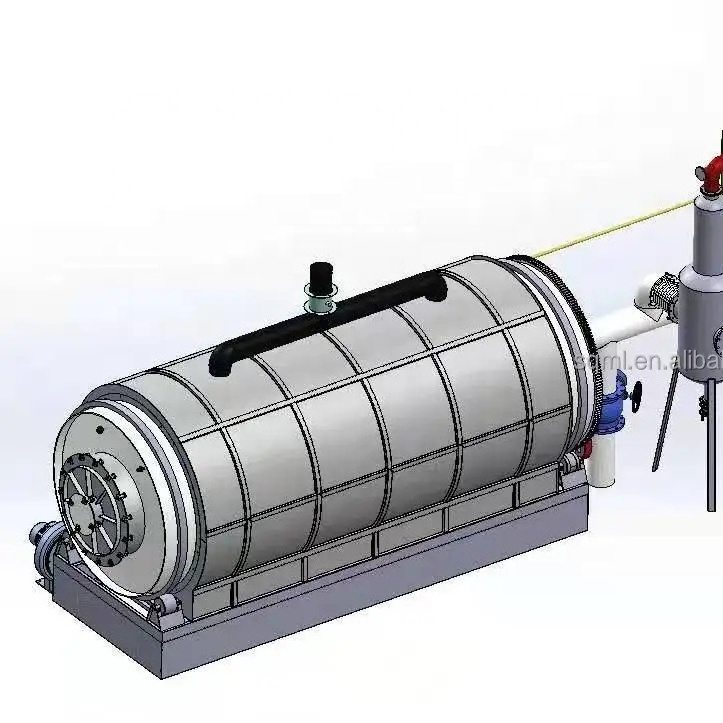

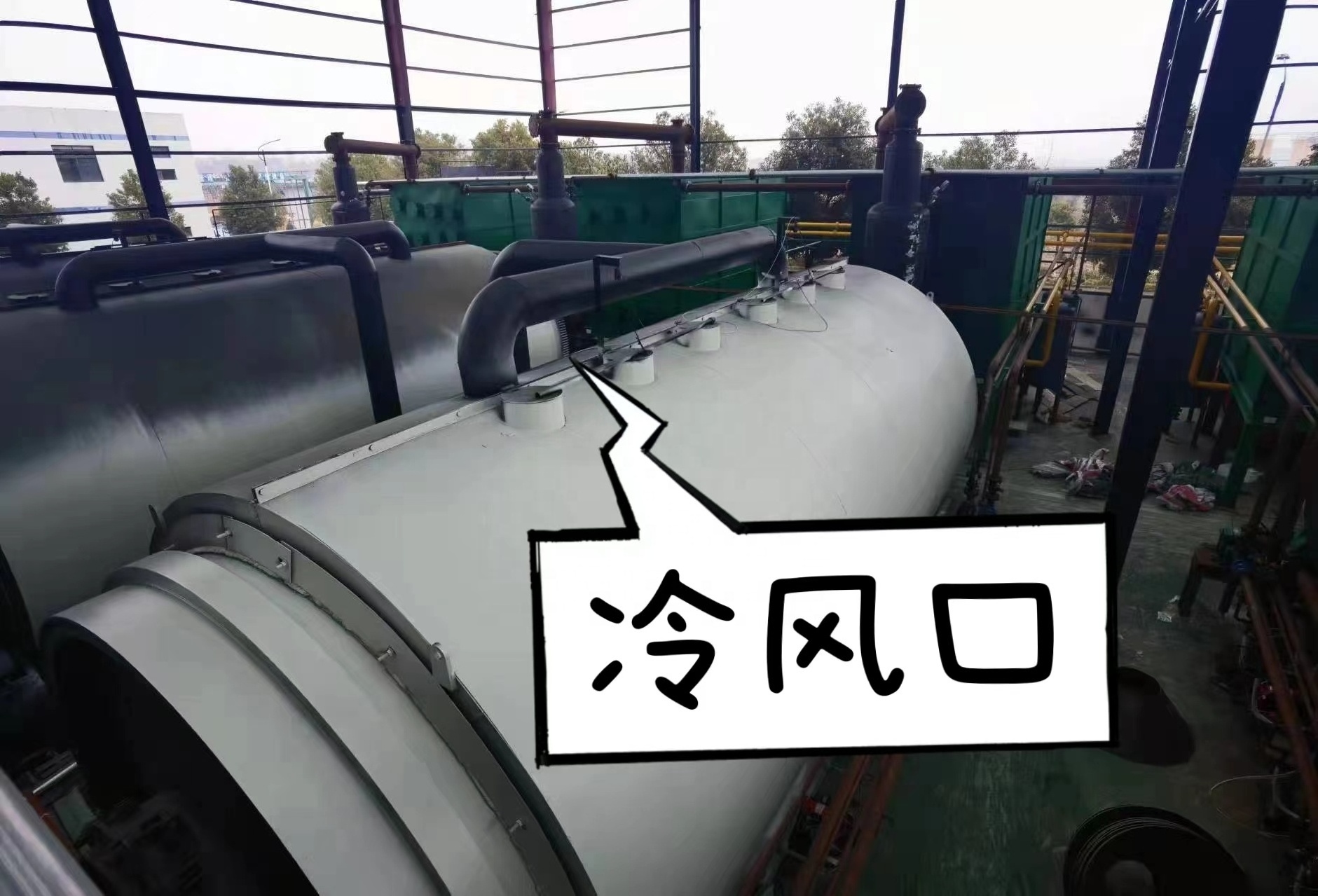

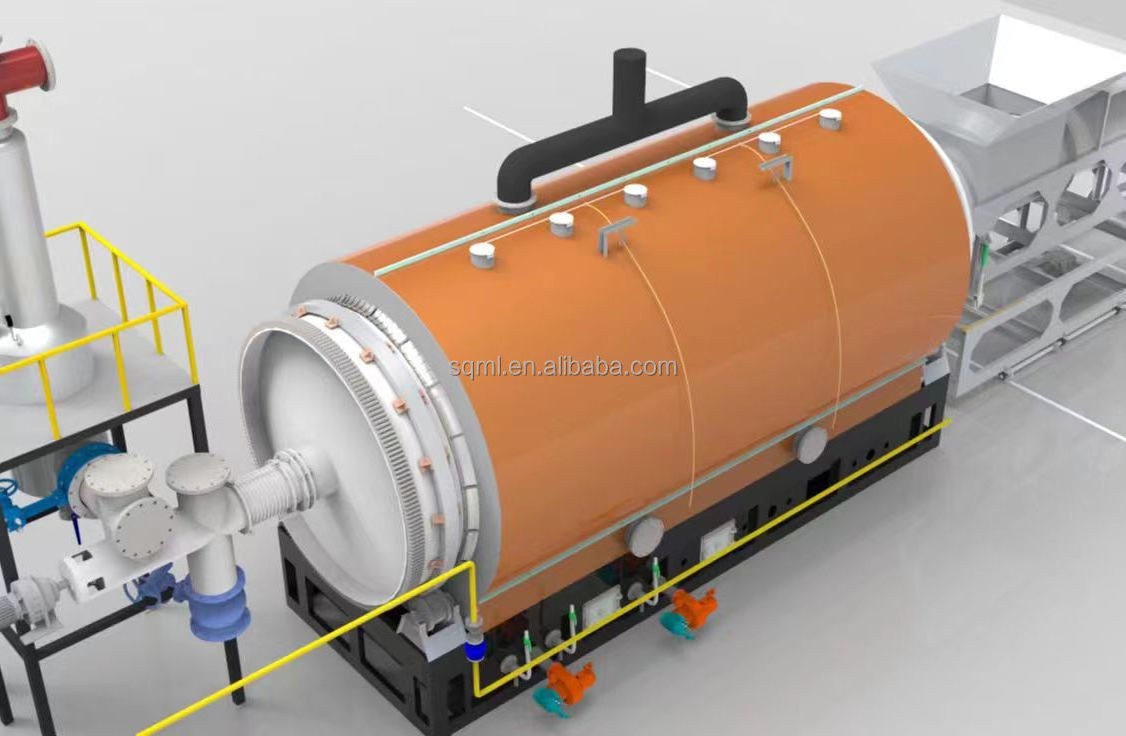

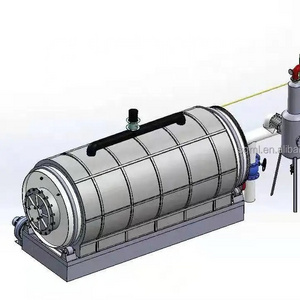

Pyrolysis Reactor :

The reactor thickness is 16mm or 18mm , It can improve reactor use life time, and ensure reactor no deformation when high temperature heating.

Auto slag discharge system

1.Shorten Cooling time .

2.Realize high temperature discharge

3.Water is cold and pollution free

4.Automatic screw discharge discharging .

Recommend Products

Ming sen Project

Our SERVICE

Hot Searches