- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

900

-

Voltage:

-

110V/220V/380V/415V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

AUTOMPACK

-

Dimension(L*W*H):

-

2150mm*1350mm*1300mm

-

Keyword:

-

Oil Milk Jelly Peanut Butter Salad Spout Bag liquid Packing Machine

-

Bag size:

-

L110-330mm; W90-210mm

-

Measuring range:

-

50-1000ml

-

Packing speed:

-

20-60bag/min

-

Optional Devices:

-

Code printer, material elevator, conveyor, weigher, etc

-

Bag type:

-

Preformed bags, block bottom, zip-lock recloseable bag, stand-up pouch

-

Control system:

-

CPU/PLC

-

Package Accuracy:

-

Error≤±0.5-1%; depending on type of products

-

Pneumatic Parts:

-

PneumaticscomponentAirtac/BOOKA Vacuum generator/Vacuum Filter

-

Gas Consumption:

-

0.65m3/M3

Quick Details

-

Function:

-

FILLING, Wrapping, Labeling, Capping, Sealing, Gluing, counting

-

Packaging Type:

-

Cartons, CANS, Bottles, Barrel, Stand-up Pouch, Bags, Film, Pouch, case

-

Packaging Material:

-

Plastic, Paper

-

Weight (KG):

-

900

-

Voltage:

-

110V/220V/380V/415V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

AUTOMPACK

-

Dimension(L*W*H):

-

2150mm*1350mm*1300mm

-

Keyword:

-

Oil Milk Jelly Peanut Butter Salad Spout Bag liquid Packing Machine

-

Bag size:

-

L110-330mm; W90-210mm

-

Measuring range:

-

50-1000ml

-

Packing speed:

-

20-60bag/min

-

Optional Devices:

-

Code printer, material elevator, conveyor, weigher, etc

-

Bag type:

-

Preformed bags, block bottom, zip-lock recloseable bag, stand-up pouch

-

Control system:

-

CPU/PLC

-

Package Accuracy:

-

Error≤±0.5-1%; depending on type of products

-

Pneumatic Parts:

-

PneumaticscomponentAirtac/BOOKA Vacuum generator/Vacuum Filter

-

Gas Consumption:

-

0.65m3/M3

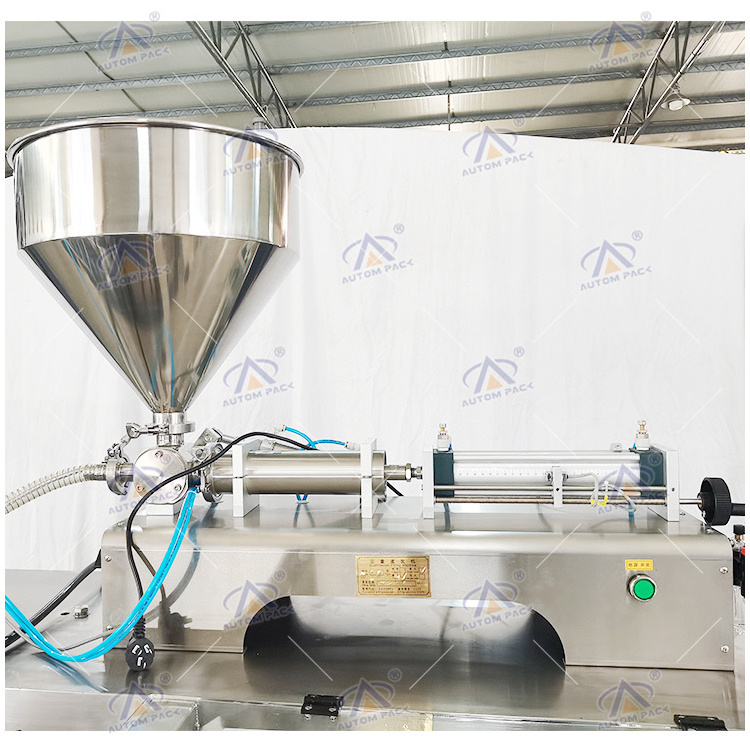

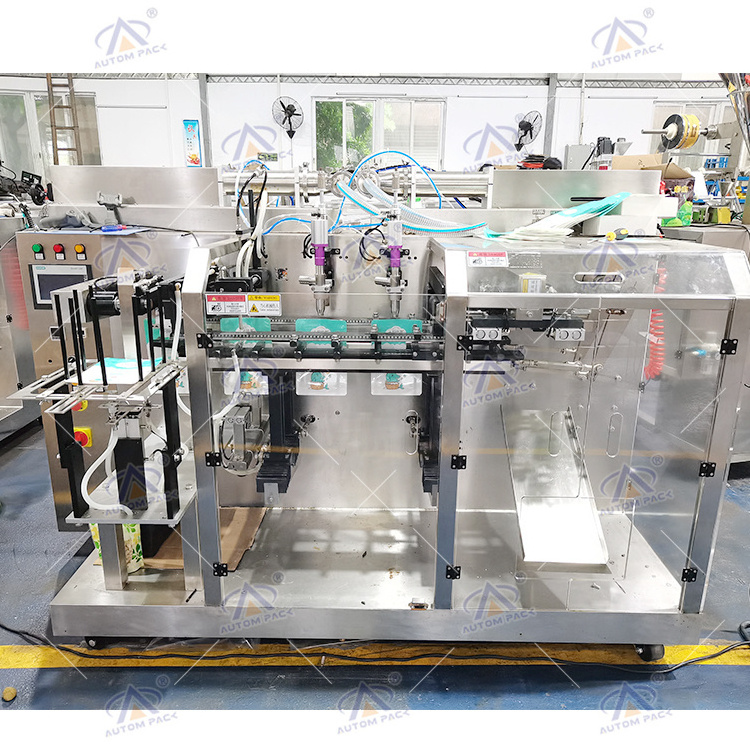

Machine Images:

ATM-160L/210L/260L Technical Parameter:

| V endor Number | ATM-160L | ATM-210L | ATM-260L |

| No. Of Working Stations | Horizontal type FFS premade pouch packing machine | ||

| Bag Size |

L: 100-190mm; W: 80-160mm |

L: 110-330mm; W: 90-210mm |

L: 150-400mm; W: 150-260mm |

| Weighing Range | 5-300ml | 50-1000ml | 200-2000ml |

| Bag Type | Stand bag, zipper bag, flat bag (3 side seal, 4 side seal, bag with punched hole handle, pillow bag etc.) | ||

| Packing Speed | 20-70bag/min | 20-60bag/min | 10-60bag/min |

| Package Accuracy | Error≤±0.5-1%; depending on type of products | ||

| Maximum Pouch Width | 160mm | 210mm | 260mm |

| Gas Consumption | 0.5m3/min | 0.5m3/min | 0.7m3/min |

| Air Compressor | Not less than 1 CBM; supply by user | ||

| Control Panel | 7" Color touch screen | 7" Color touch screen | 7" Color touch screen |

| Electrical Parts | Siemens PLC/Omron Power Switch/Schneider Breaker | ||

| Pneumatic Parts | PneumaticscomponentAirtac/BOOKA Vacuum generator/Vacuum Filter | ||

| Options | Zipper opening device, bag holding device, air filling device, finished conveyor, filling equipment | ||

| Total Power | 3.0KW 380V 50/60hz | 3.5KW 380V 50/60hz | 3.5KW 380V 50/60hz |

| Machine Dimensions | L1400mm*W900mm*H1050mm | L2150mm*W1350mm*H1300mm | L2450mm*W1350mm*H1350mm |

| Machine Weight | 600kg | 900kg | 1100kg |

| Feature: |

| 1,Rapid change of the specificationgs of th bag,bag width can be automati-cally adjusted by one button. |

| 2,Single shaft and the CAM design:packing speed faster;more stable operation;maintenance easier and reduce defective rate. |

| 3,Modular heating,temperature control more accurate,heating fault have alarm prompt. |

| 4,Advanced design idea,reduce the material loss,ensure the stability of enquipment opration,extend the operating life of the enquipment. |

| 5,Simple and convenient operation ,adopts the advanced PLC +POD(touch screen) electric control system and man-machine interface |

| 6,Machine have wide packaging range ,it can packaging :liquid,paste,gtanule,powder,solid various bagging materials only.According to the different material with different matering device. |

| 7,Machine use preformed bags &good sealing quality to improve the quality and grade of the product. |

| Work flow: giving bag→coding→opening→filling1→filling2→auxiliary→exhaust→heat sealing→forming and output product |