- Product Details

- {{item.text}}

Quick Details

-

Name:

-

Heat Pump Dryer

-

Material:

-

stainless Steel

-

Used for:

-

food

Quick Details

-

Place of Origin:

-

China

-

Weight:

-

233 KG

-

Dimension(L*W*H):

-

1200*680*1800mm

-

Name:

-

Heat Pump Dryer

-

Material:

-

stainless Steel

-

Used for:

-

food

Contact us get more videos and details.

1. We are a manufacturers, and all product certifications are linked to our factory.

2. We know more about the products and can get more professional answers. Delivery is more guaranteed and timely(Generally, we can ship within 48 hours after you pay). Can solve any problems for you instantly.

3.10 years of production experience makes our production capacity strong, and has a stable supply chain and production system.Withbetter R & D capabilities, it can quickly manufacture various customized machines.Welcome large or small volume OEM / OEM.

4. Cooperate with big brands from many countries and have experience selling to Europe, North America, South America, Asia,Africa,Middle East and other regions, making the transaction smoother

2. We know more about the products and can get more professional answers. Delivery is more guaranteed and timely(Generally, we can ship within 48 hours after you pay). Can solve any problems for you instantly.

3.10 years of production experience makes our production capacity strong, and has a stable supply chain and production system.Withbetter R & D capabilities, it can quickly manufacture various customized machines.Welcome large or small volume OEM / OEM.

4. Cooperate with big brands from many countries and have experience selling to Europe, North America, South America, Asia,Africa,Middle East and other regions, making the transaction smoother

HEAT PUMP DRYER MACHINE

1.

Touch screen control with drying operating system

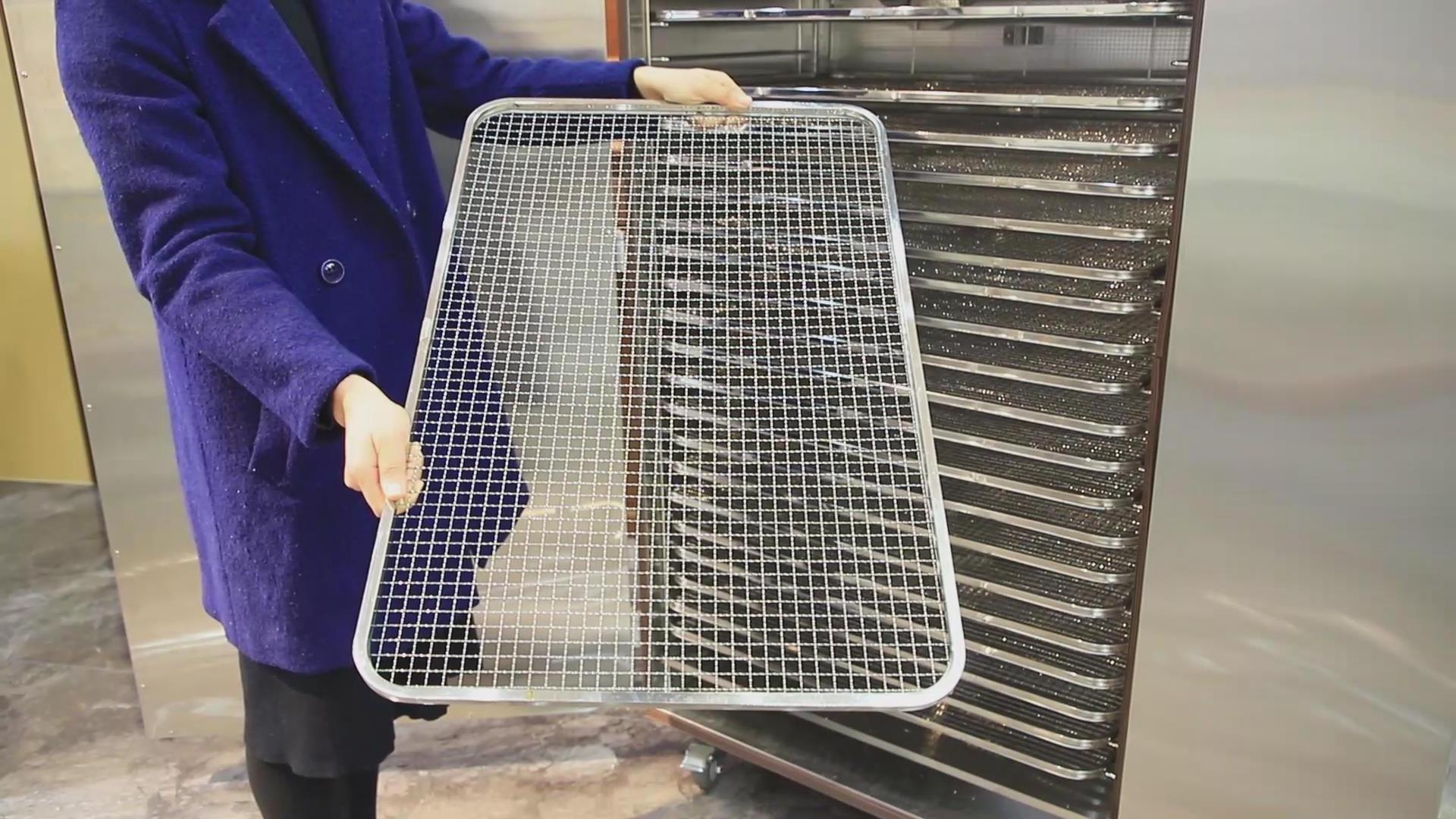

2. 24 trays, capacity is 698L

3. Thickened

0.8mm

, brushed stainless steel shell.

304 food grade trays

.

4. The trays size is

78X49cm,

and the trays spacing of each trays is

5cm

5. Timing range:

495 hours

with normal opening function, temperature setting range:

40~75℃

6. You can bake fruits, vegetables, meat, grains, herbs, beans, snacks, et

c

|

Product model

|

RBM-A01

|

|

Layer mesh specification (mm)

|

790x620x10MM, with a spacing of 50mm between the upper and lower layers

|

|

Total area of layer network

|

11.8 square meters

|

|

Net weight

|

199KG

|

|

Gross weight

|

277KG

|

|

Rated voltage/frequency

|

220VAC/50Hz

|

|

Rated input power (heat pump

|

1420W

|

|

Heating tube power (electric heating)

|

1300W

|

|

Heating capacity (heat pump)

|

5950W

|

|

Maximum input power of the entire machine

|

1710 W+1300 W

|

|

Maximum input current (heat pump)

|

8A

|

|

Maximum input current of the entire machine

|

14A

|

|

Dehydration rate

|

3 kg/h (temperature 55/humidity 70%)

|

|

Dehydration power consumption

|

40~75℃

|

|

Air outlet temperature

|

243 kgs / 320 kgs

|

|

Operating ambient temperature

|

-10~45℃

|

|

noise

|

≤ 65(dB)A

|

|

Waterproof grade

|

IPX0

|

|

Product size (mm)

|

1180x685x1780

|

|

Packaging size (mm)

|

1260x780x1810

|

|

Refrigerant/Weight

|

R134a/830g

|

|

Maximum system pressure

|

3.0MPa

|

|

capacity

|

698L

|

|

timing

|

6 stages, each lasting 100 hours for a total of 600 hours

|

ODM project process

1.Communication Requirements: Customer provide sample or design paper with details requirements.

2.factory quoting: quotation is passed by customer and factory provide die design.

3.making prototype: within 5-7days, provide the 1:1 mock-up

4.confirmation of prototype: customer confirm the 1:1 mock-up after several adjustment

5.Opening mould. Produce the mould according to the confirmation of 1:1 mock-up,takes around 1-2months

6.testing mould. Try the mould repeatedly and make sure there is no flaws on finished products.

7.Trial production. Small mass production after passing the mould testing and do fully product test

8.Mass production. Start mass production after passing the trial production, and customer pay the deposit.

9.Inpection&delivery. Delivery within 4 weeks, customer arrange the balance payment.

Our company has perfect equipment and high-quality technical team, can customize products according to customer requirements.

2.factory quoting: quotation is passed by customer and factory provide die design.

3.making prototype: within 5-7days, provide the 1:1 mock-up

4.confirmation of prototype: customer confirm the 1:1 mock-up after several adjustment

5.Opening mould. Produce the mould according to the confirmation of 1:1 mock-up,takes around 1-2months

6.testing mould. Try the mould repeatedly and make sure there is no flaws on finished products.

7.Trial production. Small mass production after passing the mould testing and do fully product test

8.Mass production. Start mass production after passing the trial production, and customer pay the deposit.

9.Inpection&delivery. Delivery within 4 weeks, customer arrange the balance payment.

Our company has perfect equipment and high-quality technical team, can customize products according to customer requirements.

Hot Searches