- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

50L-2T,Customized, Customized

-

Weight (KG):

-

1000 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LIENM

-

Voltage:

-

380V/220V,Customized

-

Dimension(L*W*H):

-

Custom Made

-

Power (kW):

-

22 kW

-

Warranty:

-

1 YEAR

-

Product name:

-

Vacuum Emulsifying Mixer

-

Machine Type:

-

Emulsifier

-

Speed of homogenizer:

-

2880 R/M

-

Heating method:

-

Steam or electricity

-

Stirrer type:

-

Tank Mixer

-

Control:

-

PLC+ Touch Screen

-

Feature:

-

High Efficiency Low Cost

-

Usage:

-

Produce cream, gel, lotion, shampoo,etc

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

ISO9001,CE

Quick Details

-

Barrel Volume (L):

-

500

-

Max. Loading Volume (L):

-

5000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 3500 r.p.m

-

Max. Loading Capacity:

-

50L-2T,Customized, Customized

-

Weight (KG):

-

1000 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LIENM

-

Voltage:

-

380V/220V,Customized

-

Dimension(L*W*H):

-

Custom Made

-

Power (kW):

-

22 kW

-

Warranty:

-

1 YEAR

-

Product name:

-

Vacuum Emulsifying Mixer

-

Machine Type:

-

Emulsifier

-

Speed of homogenizer:

-

2880 R/M

-

Heating method:

-

Steam or electricity

-

Stirrer type:

-

Tank Mixer

-

Control:

-

PLC+ Touch Screen

-

Feature:

-

High Efficiency Low Cost

-

Usage:

-

Produce cream, gel, lotion, shampoo,etc

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

ISO9001,CE

Product Description

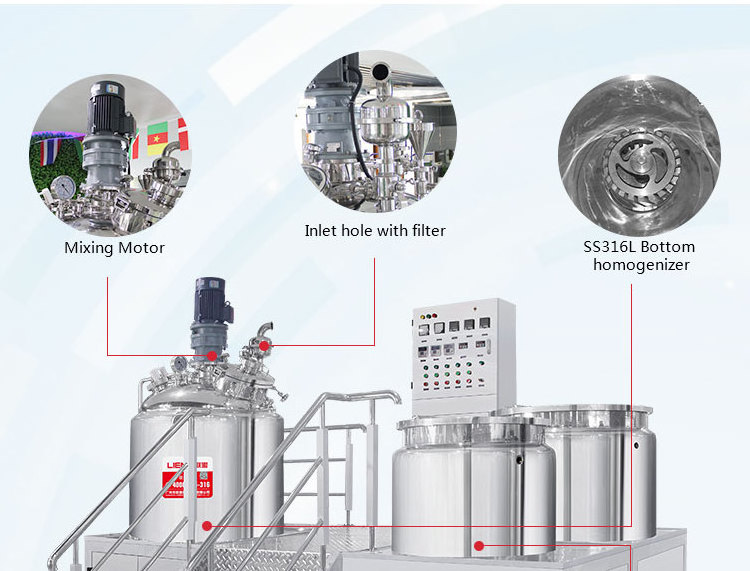

Vacuum Mixer Tank Ointment Production Emulsificante Salad Dressing Snail Cream Making Machine

Introduction:

1, The triple mixing adopts the imported frequency inverter for speed adjustment,which can meet different technological demands.

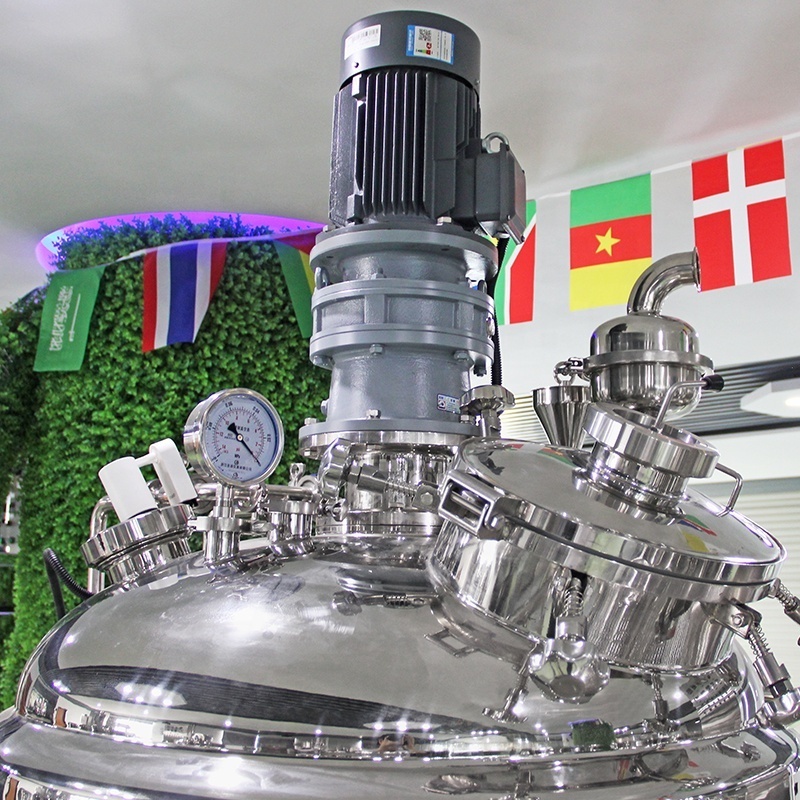

2, The homogenizing structure is made through German techology. The machine adopts the improted double-end mechanical seal effect.The maximum emulsifying rotation speed can reach 3500rpm and the high shearing fineness can reach 0.2-5um.

3, The vacuum defoaming can make the materials meet the requirement of being aseptic . The vacuum materials vacuum sucking can avoid dust.

4, The main boiler lid can adopt lifting system, it is easy to clean and the cleaning effect is more obvious, the main boiler can adopt tilting discharge.

5, The boiler body is welded with 3 layer imported SS plate, tank body and pipes adopts mirror polish whcih meet the GMP standard.

6, According to process requirement, the tank body can heating and cooling the electric heating.

7, To ensure the stability of whole machine, the machine adopt the imported electric appliances which can meet the international standards.

2, The homogenizing structure is made through German techology. The machine adopts the improted double-end mechanical seal effect.The maximum emulsifying rotation speed can reach 3500rpm and the high shearing fineness can reach 0.2-5um.

3, The vacuum defoaming can make the materials meet the requirement of being aseptic . The vacuum materials vacuum sucking can avoid dust.

4, The main boiler lid can adopt lifting system, it is easy to clean and the cleaning effect is more obvious, the main boiler can adopt tilting discharge.

5, The boiler body is welded with 3 layer imported SS plate, tank body and pipes adopts mirror polish whcih meet the GMP standard.

6, According to process requirement, the tank body can heating and cooling the electric heating.

7, To ensure the stability of whole machine, the machine adopt the imported electric appliances which can meet the international standards.

Specification

|

Product

|

Vacuum Homogenizer Emulsifier Cream Lotion Mixing Tank

|

|

Type

|

Fixed type

|

|

Heating method

|

Steam or electricity

|

|

Control

|

Manual or by touch screen

|

|

Product capacity

|

50L-2T, customized

|

Product Category:

Hot Sale Shampoo Vacuum Emulsifying Mixer, Face Cream Making Machine composed of pretreating boilers, vacuum emulsifying and blending boiler, hydraulic lifting system, dumping system, electric control system and work platform etc.

Safeguard:

1. If the mixer, homogenizer or power grid is overburden, the machine will stop automatically.

2. It will exhaust automatically when the vapor pressure in the pot is over the settled pressure.

3. It will drain off water if the pressure is over the settled pressure when the cooling water for the main pot enters the interlayer.

4. The security marks are sticked on the rack, electric box and the other operation table.

Application:

Suitable for production of ointment and cream products in cosmetic and pharmaceutical plants. The emulsifying effect is more prominent for materials of high base viscosity and high solid content.

Recommend Products

Hot Searches