- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

700

-

Dimension(L*W*H):

-

2800*2550*2650

-

Weight (T):

-

11 T

-

Range of Spindle Speed(r.p.m):

-

1 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

7.5-11

-

Max. Table Load(kg):

-

1000 kg

-

Feed Speed(mm/min):

-

1 - 8000 mm/min

-

Rapid Feed Speed(m/min):

-

36/1

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yijincnc

-

Voltage:

-

220V/380V

-

Marketing Type:

-

New Product 2023

-

Machine Type:

-

customizable

Quick Details

-

Table Size (mm):

-

1400*700

-

Number of Axes:

-

3, 4, 5

-

Table Travel (X) (mm):

-

1300

-

Table Travel (Y) (mm):

-

700

-

Dimension(L*W*H):

-

2800*2550*2650

-

Weight (T):

-

11 T

-

Range of Spindle Speed(r.p.m):

-

1 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

7.5-11

-

Max. Table Load(kg):

-

1000 kg

-

Feed Speed(mm/min):

-

1 - 8000 mm/min

-

Rapid Feed Speed(m/min):

-

36/1

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yijincnc

-

Voltage:

-

220V/380V

-

Marketing Type:

-

New Product 2023

-

Machine Type:

-

customizable

Product Description

Detailed configuration

1

.

Spindle unit, up to 8000rpm;

2. CNC system KND2000, spindle motor 7.5Kw;

3. Automatic release knife, pneumatic cutting mechanism;

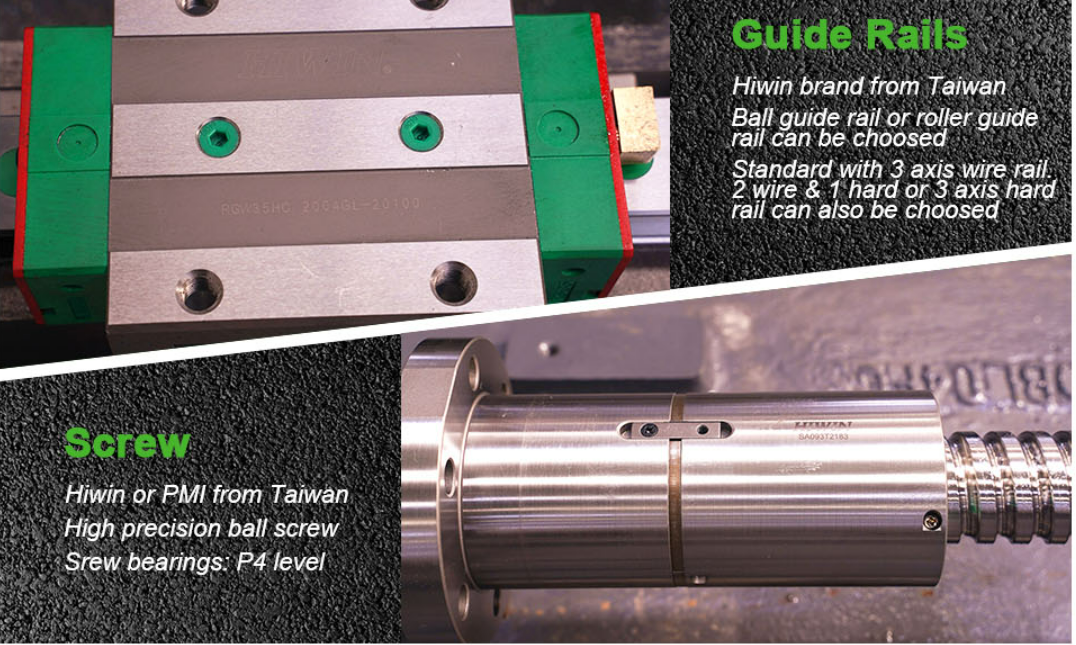

4. Automatic centralized forced oil lubrication for screw and guide rails;

5. High pressure water cooling;

6. Air cooling;

7. Fully protective sheet metal cover;

8. 24 disc type tool libraries;

9. Mobile hand operated pulse generator;

10. RS232 interface;

11. Three color alarm light;

Product Introduction and Usage

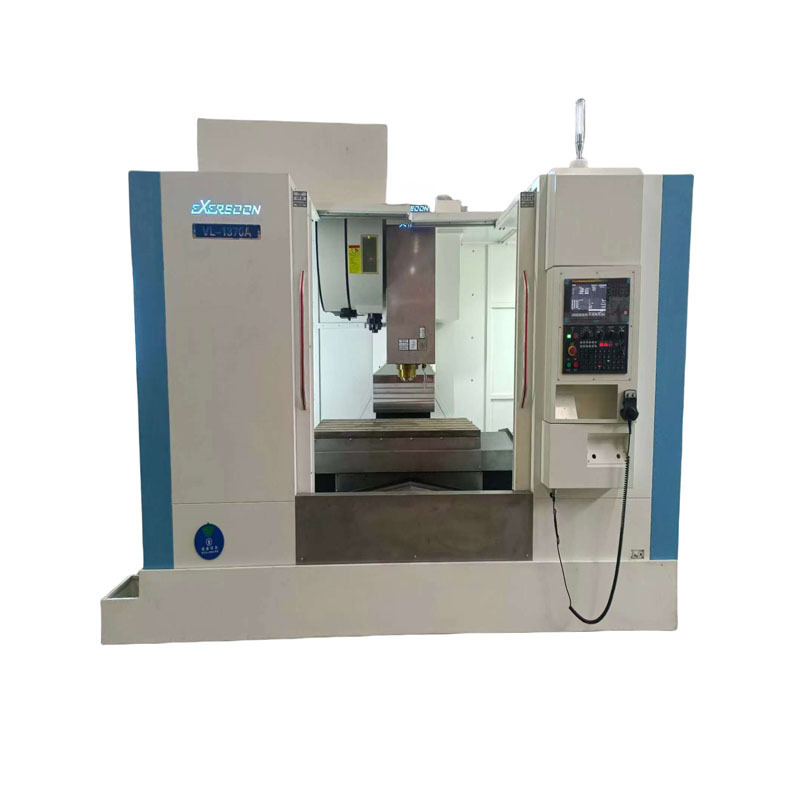

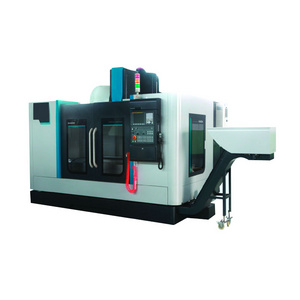

VMC1370Vertical machining centers are mainly used for processing high-precision, multi process, and complex shaped parts such as

plates,

discs, shells, molds, etc. It can complete milling, drilling, expanding, reaming, boring and other processes continuously in one

clamping operation. Programmable tapping and precision machining of 2D and 3D surfaces and slopes, shortening production cycles

and enabling users to achieve good economic benefits.

plates,

discs, shells, molds, etc. It can complete milling, drilling, expanding, reaming, boring and other processes continuously in one

clamping operation. Programmable tapping and precision machining of 2D and 3D surfaces and slopes, shortening production cycles

and enabling users to achieve good economic benefits.

Product Paramenters

|

Model

|

VMC1370

|

|

Main Motor Power KW

|

11KW

|

|

Spindle Max. Rotating Speed

|

Servo Spindle 8000rpm

|

|

Z Motor Torque

|

22 N.m

|

|

X Motor Torque

|

22 N.m

|

|

Y Motor Torque

|

22 N.m

|

|

Spindle Taper

|

BT40

|

|

Worktable Size

|

1400X700mm

|

|

Travel(Longitudinal X/Horizontal Y/Vertical Z)

|

1300X700X700mm

|

|

Spindle nose to table surfacespindle nose to table surface

|

110-810mm

|

|

Spindle axis to column surface

|

750 mm

|

|

T-slot width:

|

18

|

|

Positioning Accuracy

|

0.008mm

|

|

Repeated Positioning Accuracy

|

0.003mm

|

|

Machine Overall Dimension (L*W*H) mm

|

3800*2750*2800

|

|

Machine Net Weight KG

|

2400

|

|

Magazine Capacity

|

24 (Bamboo Hat)

|

|

System Configuration

|

Siemens 828D

|

|

External Protection Level

|

Full Closed

|

01

The system has complete and reliable interlocking, safety protection, fault diagnosis and alarm functions, and is equipped with a USB/RS232 standard communication interface. It can be programmed and stored with a computer, and can achieve DNC processing (depending on the system).

02

The main basic components such as the base, sliding seat, workbench, column, and spindle box are made of high-strength cast iron; The base is a box structure, and the compact and reasonable symmetrical reinforcement structure ensures the high rigidity and bending and shock absorption performance of the foundation components.

03

The spindle adopts a central blowing structure, which quickly cleans the inner cone of the spindle with central high-pressure gas when the spindle is loosened, ensuring the accuracy and lifespan of the tool clamping.

Sales Country

Hot Searches