- Product Details

- {{item.text}}

Quick Details

-

Machines material:

-

Food grade stainless steel 304

-

Whatsapp/Mob:

-

+86-15553816454

-

Application:

-

Corn flakes,rice crispies,cereal snacks

Quick Details

-

Place of Origin:

-

Shandong, China

-

Name:

-

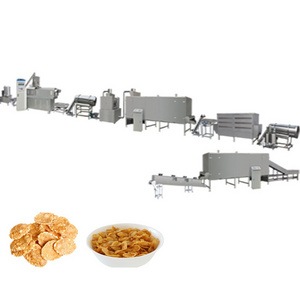

Kelloggs Corn Flake Production Line Price

-

Company:

-

Jinan DG machinery co.,ltd

-

Machines material:

-

Food grade stainless steel 304

-

Whatsapp/Mob:

-

+86-15553816454

-

Application:

-

Corn flakes,rice crispies,cereal snacks

1.Mixer : Mix the raw material equally

2.Conveyor : take the raw material to the extruder

3.Twin screw extruder : Mix and cook raw material

4.Vibrator : spread the pellet balls to avoid them sticking together

5.Air blower : blow the pellet balls to the flaker

6.Flaker: Press the snack balls into flakes with adjustable thickness

7.Blower : Blow the corn flakes to the oven

8.Oven : dry the corn flakes to take away most of the moisture content

9.Elevator : take the corn flakes to the next machine

10.Hot air popper : puff the corn flakes to be expanded and crispy

11.Coating system : spray syrup onto the surface of the corn flakes to make sweet flavor

12.Spreader : spread the coated corn flakes to avoid sticking together

13.Oven (extended ) : Bake the coated corn flakes to make them crispy again after syrup coating .

14.Cooling conveyor : cool down and convey the corn flakes

| Model | Installed power | Power consumption | Throughput | Dimension |

| DG32-II processing line | 135KW | 101KW | 60-80kg/h | 45X2.8X2.7M |

| DG52-II processing line | 210kw | 168KW | 100-150kg/h | 54.7X2.8X2.7M |

| DG75-II processing line | 292KW | 219KW | 200-250kg/h | 64.2X3.2X3.1M |

| DG75-II B processing line | 342KW | 256KW | 300-350kg/h | 69X3.3X3.8M |

Main characters of DG traditonal type twin screw extruder

1.Frequency converter to control feeding device,extrusion screw,rotating cut.

2.well desinged screw sets for singel screw extruder and twin screw extruder ,widely application,low cost.

3.Wearable alloy steel screw lives a long life.

4.Imported bearing group with higher bearing capacity

5.Automatic lubrication system ensure running stable and long life

6.Self-cleaning function and different slenderness ratios is another feature of twin screw extruder

Main characters of advanced new type DG twin screw extruder

1.Swiss Technology,made in China;

2.PLC touch screen for Centralized ,accurate,convenient control

3.Fully automatic control system for heating and circulated cooling accurately

4.Direct transmission of motor and distribution box reduces energy loss.

5.Imported bearing group with higher bearing capacity

6.Equip with water injecting device on barrel to meet require of various raw material and quality.

7.High-speed tool steel with hardness HRC≥62 to ensure a longer service life.

8.Modular combination of screws at will to meet require of different raw material.

9.Suspension type rotary cutter with bearing adjusting device to ensure quick,safe and accurate

10.All barrels inlaid alloy sleeve, easy to replace and extend the life span of screw.

11.All barrels inlaid cooling water through, spread around alloy sleeve, and can accurate constant temperature required

12.All screw sleeves is kneading, ensure that not accumulate material.

13.The screw is installed by blocks, and can be replaced optionally ratio to achieve requirements for product.

14.Screw sleeve is installed by spline, and it is convenient and efficient.

15.Quality of screw sleeve according to different prices is divided into: Cr12MoV, 38CrMoAl38, 6542.

16.Applied to make all kinds of extrusion products such as corn flakes ,cereal snacks ,puff snacks ,wheaten snacks , 2d /3d snack pellets , pet food ,fish feed ,soya protein ,nutritiobal powder ,modified starch and so on .

- Machine material : 201 ss / 304 ss as required

- Screw / barrel and cutter of the extruder : special alloy to bear high temp and pressure

- Main motor: Siemens brand

- Touch screen : Wenview brand

- Miniature circuit breaker : ABB brand

- Alternating current contactor : ABB brand

- Thermal Relay: ABB brand

- Moulded case circuit brake : CHNT brand

- Small relay: Weidmuller brand

- Inverter: Delta brand

- PLC system: Delta brand

- Burner: Baltur brand

- Bearing : NSK/ SKF brand

I. DG has professional team to design the whole production line according to your requirements

II. we also help our client to develop the old production line and carry out new products

III. Custiomized factory layout designed is provided by our professionals

IV. Overseas technicians are available to help the clients for installation and adjustment

V. 12 months warranty for the machines , 24 months for some parts

Turkey project in Russia

After-Sales Service

Training how to install the machine, training how to use the machine.

Engineers available to service machinery overseas

Spare parts offering with favorable price.

New products testing for the clients