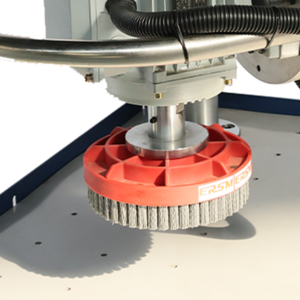

The sanding belt with clean device to clean the belt ,increase the service life of belt ,improve the sanding quality.

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

3900 KG

-

Name:

-

Metal Brushing Deburring Edge Rounding Sanding Machine

-

Application:

-

Sanding and polishing of solid wood, MDF, veneer

-

Types:

-

Planer sanding, Upper float sanding for UV, Veneering sanding

-

Processing thickness(mm):

-

100,150

-

Sanding motor power(kw):

-

Frequency motor 7.5, 11, 22, 30

-

Sanding frames quantity(pcs):

-

2,3

-

Dust collector brush motor power(kw):

-

0.37

-

Lift motor power(kw):

-

0.37, 0.75

-

Sanding speed(m/s):

-

12, 18, 22

-

Working pressure(mpa):

-

0.6-0.8

Quick Details

-

Place of Origin:

-

China

-

Machine Type:

-

Wood wide belt sanding

-

Core Components:

-

Sanding frame

-

Weight (KG):

-

3900 KG

-

Name:

-

Metal Brushing Deburring Edge Rounding Sanding Machine

-

Application:

-

Sanding and polishing of solid wood, MDF, veneer

-

Types:

-

Planer sanding, Upper float sanding for UV, Veneering sanding

-

Processing thickness(mm):

-

100,150

-

Sanding motor power(kw):

-

Frequency motor 7.5, 11, 22, 30

-

Sanding frames quantity(pcs):

-

2,3

-

Dust collector brush motor power(kw):

-

0.37

-

Lift motor power(kw):

-

0.37, 0.75

-

Sanding speed(m/s):

-

12, 18, 22

-

Working pressure(mpa):

-

0.6-0.8

Woodworking

wide belt wood

kitchen cabinet door

plywood sanding machine

Application

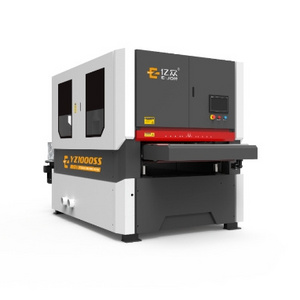

Precise wide belt sander sanding machine

Sanding machine is suitable for rough and fine sanding, grinding and polishing of all kinds of solid wood, MDF, veneer and other materials, conventional wood lines and planks, such as regular surfaces, special-shaped surfaces, and plain surface.

It can be realized by the combination of different components and different abrasives.

It is an ideal equipment for the production of special-shaped sanding such as doors, windows, cabinets, and furniture.

Raw material and finished products

Wood door before sanding

Smooth door surface after sanding

Wood furniture cabinet feeding into sanding machine

Final wood cabinet after sanding and polishing

Wood board before sanding

Uniform surface board after sanding process

Specification

1.Planer sanding machine

Planer roller and sanding combining rollers, planning firstly and then sanding, effective and saving energy.

The planer roller fixed with air pressing facility, Anti-rebound pressing roller and system, it can prevent rebounding of the material and denting.

The planning blade densely distributed at spiral type, it's good for high volume planning with high smoothness,efficiency and precision.

The planer roller fixed with air pressing facility, Anti-rebound pressing roller and system, it can prevent rebounding of the material and denting.

The planning blade densely distributed at spiral type, it's good for high volume planning with high smoothness,efficiency and precision.

Spiral planning knives applied before sanding

Anti-rebound pressing roller

|

Model

|

SK-R-RP650

|

SK-R-RP1000

|

SK-R-RP1300

|

|

Working Thickness(mm)

|

10-150

|

10-150

|

10-100

|

|

Shortest Processing Length(mm)

|

440

|

440

|

480

|

|

Planer motor power(kw)

|

7.5

|

11

|

22

|

|

First sand frame motor power(kw)

|

7.5(11)

|

11(22)

|

22(30)

|

|

Second sand frame motor power(kw)

|

7.5

|

11

|

22

|

|

Transmission motor power(kw)

(frequency control of motor speed) |

1.5

|

2.2

|

4

|

|

Dust collector brush motor power(kw)

|

0.37

|

0.37

|

0.37

|

|

Lift motor power(kw)

|

0.37

|

0.37

|

0.37

|

|

Planer knife line speed(m/s)

|

36

|

36

|

36

|

|

Sanding belt size(mm)

|

1900*660

|

2200*1020

|

2200*1020

|

|

Line speed of first sanding frame(m/s)

|

22

|

22

|

22

|

|

Line speed of second sanding frame(m/s)

|

18

|

18

|

18

|

|

Working pressure(mpa)

|

0.55

|

0.6

|

0.6-0.8

|

|

Vacuum air volume(m3/h)

|

8000

|

12000

|

15000

|

2.Upper float sanding machine for UV production

Upper floated Sander is the sanding machine can work together with other woodworking machines in production line ,and it can fit with any machines to combination production line.

lt can improve production efficiency.

The sanding roller adopts frequency control, can meet all demand of sanding process.

The sanding belt with clean device to clean the belt ,increase the service life of belt ,improve the sanding quality.

lt can improve production efficiency.

The sanding roller adopts frequency control, can meet all demand of sanding process.

The sanding belt with clean device to clean the belt ,increase the service life of belt ,improve the sanding quality.

Sanding belt with clean device

Funiture with primer paiting before sanding

Final funiture after sanding

|

Model

|

SFR-RD650

|

SFR-RD1000

|

SFR-RD1300

|

|

Working Thickness(mm)

|

2-150

|

2-150

|

2-100

|

|

Shortest Processing Length(mm)

|

280

|

320

|

380

|

|

First sand frame motor power(kw)

|

5.5

|

7.5(11)

|

15(18.5)

|

|

Second sand frame motor power(kw)

|

5.5

|

7.5(11)

|

11(15)

|

|

Transmission motor power(kw)

(frequency control of motor speed) |

1.5

|

1.5

|

2.2

|

|

Dust collector brush motor power(kw)

|

0.37

|

0.37

|

0.37

|

|

Lift motor power(kw)

|

0.75

|

0.75

|

0.75

|

|

Sanding belt size(mm)

|

1900*660

|

2200*1020

|

2620x1320

|

|

Line speed of first sanding frame(m/s)

|

3-12

|

3-12

|

3-12

|

|

Working pressure(mpa)

|

0.6-0.8

|

0.6-0.8

|

0.6-0.8

|

|

Vacuum air volume(m3/h)

|

3500

|

5000

|

8000

|

3.Veneer laminating sanding machine

Veneer laminating sanding machine is mainly used for panel thickness plain before laminating and precise sanding after veneer laminating;MDF precise sanding.

Eccentric enlarged rubber roller, high precision.Eccentrically lift up and down, convenient and simple.

Complete frame structure with higher stability, reduce vibration.

Vacuum absorption cooperates with pressing facility to solve the problem of thin panel sanded to broken because of laminating

deformation.

ln case of failure (lack of pneumatic pressure, abrasive belt brake, emergency brake),conveyor table drop down automatic to protect work piece free from being damaged.

Double eccentric rollers precision construction ,easy adjustment. Pressing construction ensure the boards stable during the panning.

Eccentric enlarged rubber roller, high precision.Eccentrically lift up and down, convenient and simple.

Complete frame structure with higher stability, reduce vibration.

Vacuum absorption cooperates with pressing facility to solve the problem of thin panel sanded to broken because of laminating

deformation.

ln case of failure (lack of pneumatic pressure, abrasive belt brake, emergency brake),conveyor table drop down automatic to protect work piece free from being damaged.

Double eccentric rollers precision construction ,easy adjustment. Pressing construction ensure the boards stable during the panning.

Vacuum absorption device

Equipped for sanding all kinds of rotary cut solid wood veneer and slicing veneer.

Veneer panel sanding

Veneer sanding

|

Model

|

SR-RM1300

|

|

Working Thickness(mm)

|

2-100

|

|

Shortest Processing Length(mm)

|

380

|

|

First sand frame motor power(kw)

|

30(37)

|

|

Second sand frame motor power(kw)

|

18.5

|

|

Transmission motor power(kw)

(frequency control of motor speed) |

3(4)

|

|

Dust collector brush motor power(kw)

|

0.37

|

|

Lift motor power(kw)

|

0.37

|

|

Sanding belt size(mm)

|

2200x1320

|

|

Working pressure(mpa)

|

0.6-0.8

|

|

Vacuum air volume(m3/h)

|

15000

|

Details Images

Enlarged rubber thickness-fixing roller

Enlarged rubber thickness-fixing roller, high machining accuracy, convenient, simple adjustment and lifting of eccentric shaft,reasonable layout and easy operation.

Thickness gauge controlled by buttons

The thickness gauge is controlled by buttons, with high precision and easy operation.

German Rexroth frequency conversion

The conveyor belt adopts German Rexroth frequency conversion adjustment, which is easy to operate.

Schneider electric components

The contactor adopts the French Schneider brand with high stability, the main motor is equipped with overload protection.

America Banner Sensor

Adopts America Banner Sensor to control the swing and off tracking of sanding belt.

Planning and sanding combination

Advantage

MDF cabinet wood brush polish sanding machine

1. The thickness of the work piece adopts a microcomputer button-type thickness display, which is accurate and stable.

2. The belt swing is controlled by air pressure, and the swing is stable and even.

3. The front and rear double emergency stop buttons can control the rapid braking of the equipment (wire resistance braking).

4. It is equipped with a fault display (the belt deviation from left and right, insufficient air pressure, front and rear emergency buttons), which is convenient for the basic fault judgment of the equipment.

5. The automatic lowering protection device is adopted for emergency stop of failure, which will not sand grooves on the board surface due to shutdown.

6. The conveyor belt uses a small square rubber belt, which is 2-3 times more wear-resistant than other brands.

7. The line speed of the conveyor belt is controlled by the German Rexroth inverter, which can be adjusted according to the sand products to improve the sand cutting quality.

8. Germany Pepperl+Fuchs photoelectric control belt swing and belt deviation.

9. The first group of sand racks adopts rubber rollers with a diameter of 300mm and 45°; the second group of sand racks adopts rubber rollers with a diameter of 300mm and 25°, which are more precise and delicate.

10. The lifting and lowering of the conveying bed adopts the T-shaped screw technology with high precision.

11. The pressing device adopts 7cm rubber pressing roller to make the feeding more stable and smooth.

12. The main bearing of the equipment adopts Japanese brands

13. The electric components brand selected for the equipment is Schneider.

2. The belt swing is controlled by air pressure, and the swing is stable and even.

3. The front and rear double emergency stop buttons can control the rapid braking of the equipment (wire resistance braking).

4. It is equipped with a fault display (the belt deviation from left and right, insufficient air pressure, front and rear emergency buttons), which is convenient for the basic fault judgment of the equipment.

5. The automatic lowering protection device is adopted for emergency stop of failure, which will not sand grooves on the board surface due to shutdown.

6. The conveyor belt uses a small square rubber belt, which is 2-3 times more wear-resistant than other brands.

7. The line speed of the conveyor belt is controlled by the German Rexroth inverter, which can be adjusted according to the sand products to improve the sand cutting quality.

8. Germany Pepperl+Fuchs photoelectric control belt swing and belt deviation.

9. The first group of sand racks adopts rubber rollers with a diameter of 300mm and 45°; the second group of sand racks adopts rubber rollers with a diameter of 300mm and 25°, which are more precise and delicate.

10. The lifting and lowering of the conveying bed adopts the T-shaped screw technology with high precision.

11. The pressing device adopts 7cm rubber pressing roller to make the feeding more stable and smooth.

12. The main bearing of the equipment adopts Japanese brands

13. The electric components brand selected for the equipment is Schneider.

Related Product

Transaction record and feedback

Our Service

We always look forward to your cooperation! Always final Inspection before shipment. We focus on wood working machinery ,To provide a one-stop end service from production, quality control,inspection, testing ,sales and logistics,let you enjoy best

service.

service.

Hot Searches