- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

China machine manufacturer of wire uncoiling and peeling machine

-

type:

-

CNC / semi-automatic

-

model:

-

WXC 80C

-

Color:

-

Customers' Requirements

-

Raw material:

-

ferrus matal materiala and non-ferrous metal materials

-

Diameter range:

-

20--85mm

-

Application:

-

matel bar / wire peeling machine

-

Advantage:

-

offer overseas service

-

Payment terms:

-

TT / LC

-

Delivery time:

-

3 months after receiving deposit

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HAIGE

-

Model Number:

-

WXC80C

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

China machine manufacturer of wire uncoiling and peeling machine

-

type:

-

CNC / semi-automatic

-

model:

-

WXC 80C

-

Color:

-

Customers' Requirements

-

Raw material:

-

ferrus matal materiala and non-ferrous metal materials

-

Diameter range:

-

20--85mm

-

Application:

-

matel bar / wire peeling machine

-

Advantage:

-

offer overseas service

-

Payment terms:

-

TT / LC

-

Delivery time:

-

3 months after receiving deposit

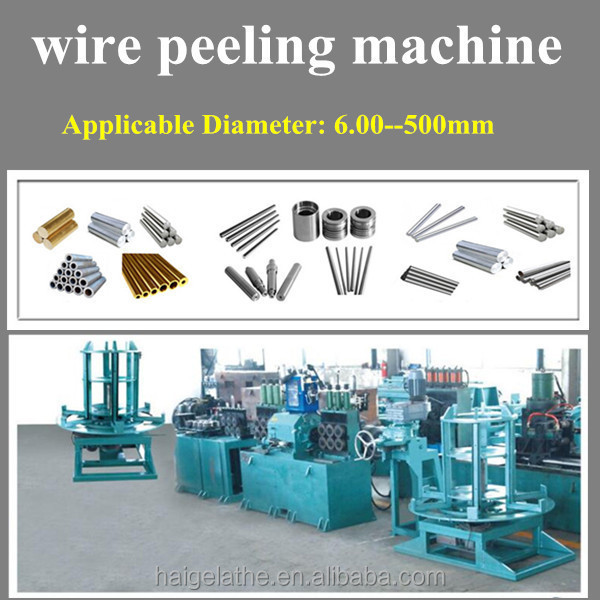

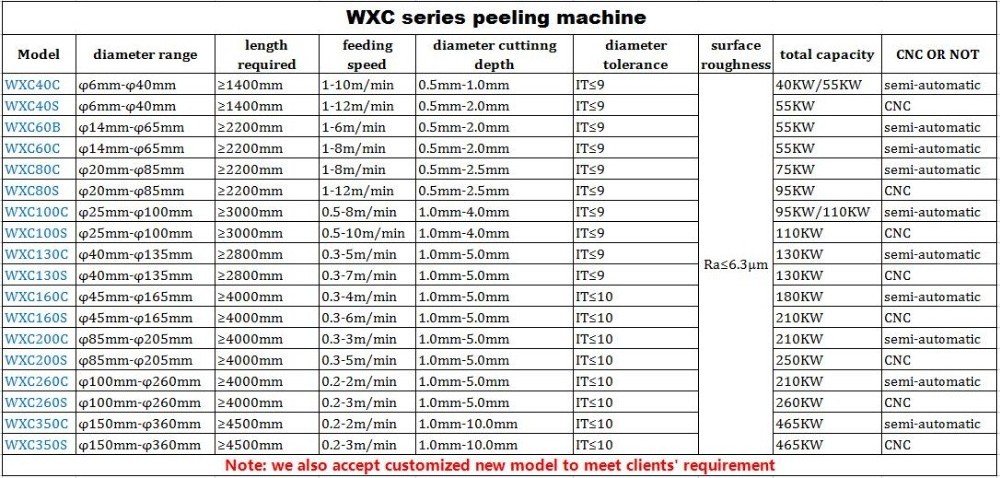

China machine manufacturer of wire uncoiling and peeling machine

Series WXC Peeling machine is a high-efficiency lathe which is specialized in processing the surface of steel round bar and steel wire rod, for example, straightening, peeling, cutting and polishing, etc.

Not only

quickly remove surface hardened layer, cracks and other defects,

but also

can get high precision.

During processing, the bar doesn’t rotate itself. The cutting tools rotates at high speed to peel the surface of the bar. At the same time, after peeled , the bar keeps walking forward.

Shapes of Workpiece are requested

long steel round bar

and

steel wire rod

.

After-sale Service System

1. Free quality guarantee period for 12 months

2. Free long-term technical support

3. Free train for buyer's operator in our factoty

4. Fast response service within 24 hours

5. Our engineers can offer overseas service, including guiding intallation, commissioning, training, etc.

The first layer

wrapping with foam film and stretch film for the special components, in order to avoid moisture.

Second layer

inside of plywood box, adopting small square plywood block and strapping belt to fix.

Third layer

the machine itself has screw fixing holes, so it can be tightly fixed on the bottom of the plywood box through screw and nut .

Fourth layer

in a container, by compact layout, reducing the gap between boxes to avoid shaking. At the same time, reinforcing between the bottom of the container and plywood boxes once again, furthermore using hanging steel wire protection.