- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

5000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Grandee

-

Year:

-

by model

-

Voltage:

-

380V/3PH/50HZ

-

Dimension(L*W*H):

-

1750*750*1700mm

-

Hollow part volume:

-

218*77*196

-

Power (kW):

-

20

-

Weight (KG):

-

1000 KG

-

Product name:

-

5liter water bottle blowing mold machine

-

Suitable bottle:

-

3L-10L PET Bottle

-

Number of capacity:

-

one cavity

-

Capacity:

-

600bph for 5000ml PET bottle

-

Type:

-

Semi-automatic Botte-blowing Machines

-

Electrical brand:

-

Mistubishi Schnieder Airtac

-

High air compressor:

-

1.2m3/30KG or 1.6m3/30KG

-

Max bottle volume:

-

10L

-

Bottle material:

-

Pet Plastic

-

Machine type:

-

Semi-automatic Bblowing Machine

Quick Details

-

Neck Diameter(mm):

-

38 mm

-

Max.Bottle Diameter(mm):

-

170 mm

-

Max.Bottle Height(mm):

-

350 mm

-

Bottle Volume(ml):

-

5000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Grandee

-

Year:

-

by model

-

Voltage:

-

380V/3PH/50HZ

-

Dimension(L*W*H):

-

1750*750*1700mm

-

Hollow part volume:

-

218*77*196

-

Power (kW):

-

20

-

Weight (KG):

-

1000 KG

-

Product name:

-

5liter water bottle blowing mold machine

-

Suitable bottle:

-

3L-10L PET Bottle

-

Number of capacity:

-

one cavity

-

Capacity:

-

600bph for 5000ml PET bottle

-

Type:

-

Semi-automatic Botte-blowing Machines

-

Electrical brand:

-

Mistubishi Schnieder Airtac

-

High air compressor:

-

1.2m3/30KG or 1.6m3/30KG

-

Max bottle volume:

-

10L

-

Bottle material:

-

Pet Plastic

-

Machine type:

-

Semi-automatic Bblowing Machine

GRANDEE MACHINE

is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10,000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions.

Products Description

Semiautomatic PET Bottle Blowing Machine:

Semi Automatic bottle blow molding machine is suitable for producing PET plastic containers and bottles from 3L to 10L. It is widely used to produce the drinking water bottle, oil bottle, carbonated drink bottle, juice bottle, pesticide bottle , daily chemical bottle, cosmetics bottle,wide-mouth Jar ,PET can etc.

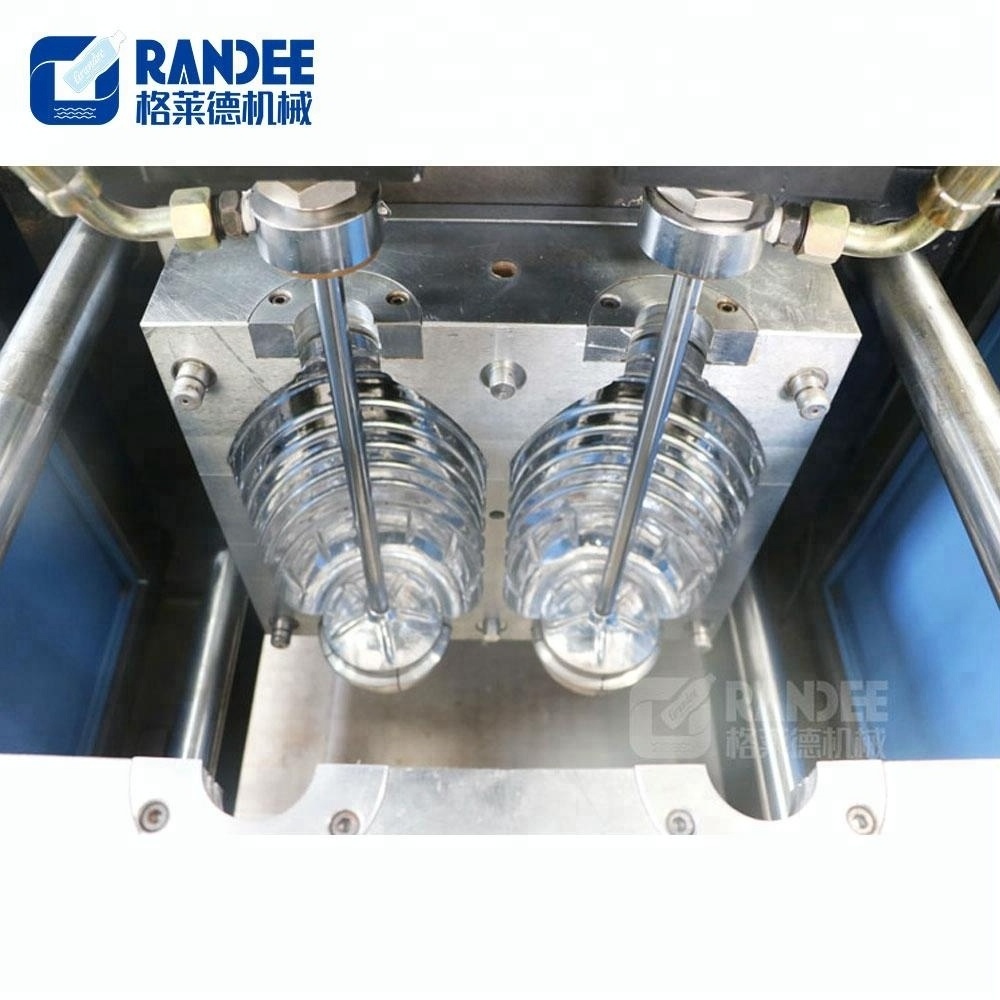

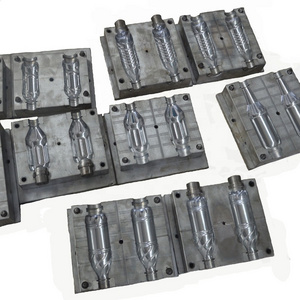

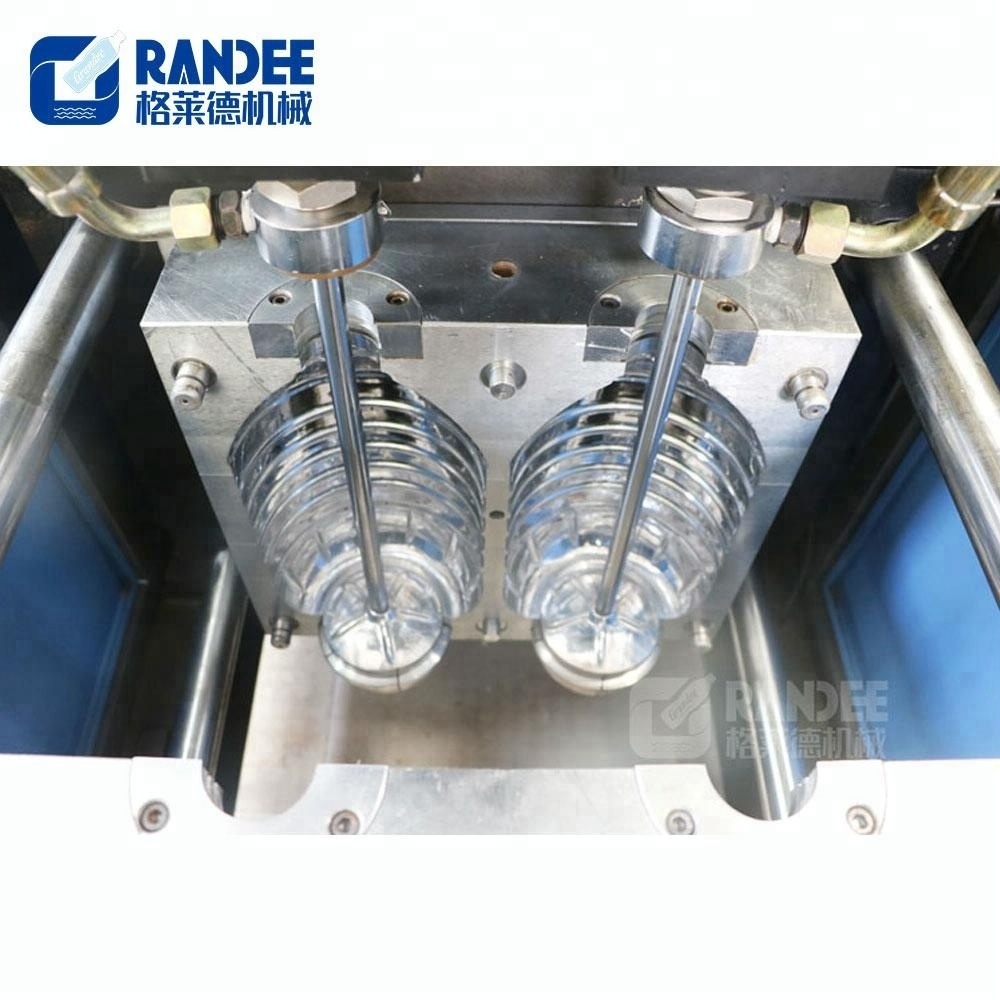

bottle blow mold

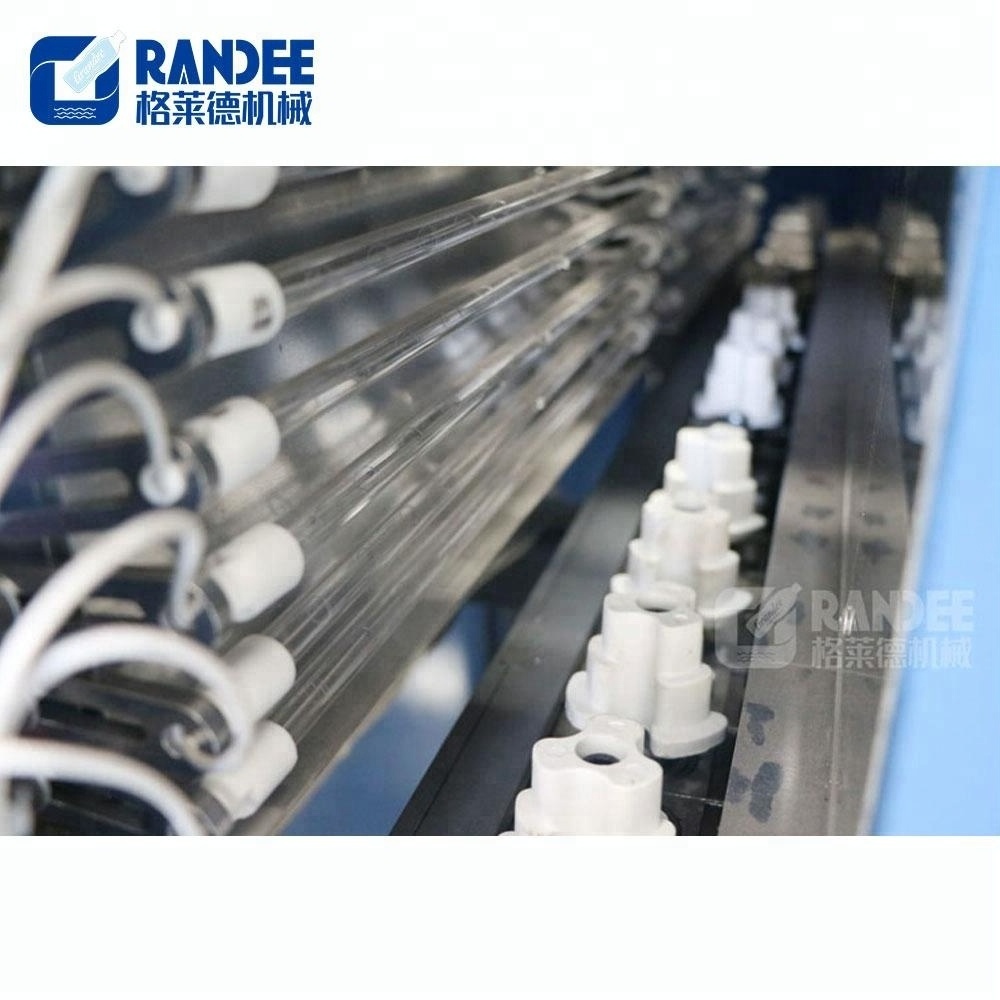

Adopting double crank to adjust mould ,heavy locking mould, stable and fast ,Adopt infrared oven to heat the perform ,the

perform rotated and heated equally.

The air system has been divided into two parts: pneumatic action part and bottle blow part to meet the different requirements

for the action and blow .It can provide sufficient and steady high pressure for blowing large irregular shaped bottles.

perform rotated and heated equally.

The air system has been divided into two parts: pneumatic action part and bottle blow part to meet the different requirements

for the action and blow .It can provide sufficient and steady high pressure for blowing large irregular shaped bottles.

Touch Screen Control

-inside heating system in the oven.- slide block system for oven

-strong infrared heating lamps

-Airtac LP valves with stronger mechanical movement(specially suitable for gallon bottle production)

-strong infrared heating lamps

-Airtac LP valves with stronger mechanical movement(specially suitable for gallon bottle production)

Infrared pre-heater

Unique heating system, accurate temperature control and easy adjustment.

Unique air storage unit.

The cooling system achieves the desired cooling effect.

Each action is driven by a cylinder instead of an oil pump, without contamination.

Unique air storage unit.

The cooling system achieves the desired cooling effect.

Each action is driven by a cylinder instead of an oil pump, without contamination.

Infrared pre-heater

Unique heating system, accurate temperature control and easy adjustment.

Unique air storage unit.

The cooling system achieves the desired cooling effect.

Each action is driven by a cylinder instead of an oil pump, without contamination.

Unique air storage unit.

The cooling system achieves the desired cooling effect.

Each action is driven by a cylinder instead of an oil pump, without contamination.

Main technical parameter

|

Model

|

GD-880

|

GD-1500

|

GD-5L

|

BL20

|

|

|

|

|||

|

Bottle sizes

|

0.1l-2L

|

0.1L-2L

|

5L-10L

|

10L-20L

|

|

|

|

|||

|

Output

|

800 bph

|

1500 bph

|

300-600 bph

|

60-150 bph

|

12000

|

14000

|

16000

|

|||

|

Max. bottle height

|

<300mm

|

<300mm

|

<400mm

|

<500mm

|

|

|

|

|||

|

Total power

|

15kw

|

17kw

|

20KW

|

20KW

|

4.5

|

5.5

|

7.5

|

|||

|

HP compressor

(m³/min 30kg)

|

1.0

|

1.2

|

1.2 or 1.6

|

1.2 or 1.6

|

2700*2100*2300

|

2970*2260*2700

|

3780*2800*2700

|

|||

|

Weight(KG)

|

500

|

800

|

1000

|

1200

|

4500

|

6500

|

8500

|

|||

Main electrical configuration

|

NAME

|

BRAND

|

AREA

|

|

PLC

|

MITSUBISHI

|

JAPAN

|

|

INVERTER

|

SCHNEIDER

|

FRANCE

|

|

CONTACTOR

|

SCHNEIDER

|

FRANCE

|

|

TOUCH SCREEN

|

MITSUBISHI

|

JAPAN

|

|

MASTER CYLINDER

|

FESTO

|

Germany

|

|

PNEUMATIC PARTS

|

AIRTAC

|

TAIWAN

|

|

ELECTRICAL PARTS

|

SCHNEIDER

|

FRANCE

|

Auxiliary equipment description

High Pressure Air Compressor Function :To provide air source for PET stretch blow molding machine, carrying out the process of

compressing air from atmosphere to the required pressure.

Air Cooling Dryer Function :To remove the moisture from the compressed air and lower temperature of the compressed air in the heat

ex-changer.

Air filter Function: To clear up the impurities out of the compressed air, like carbon hydrogen, tiny dust and solid

particles.

Turnkey Solution

Hot Searches