- Product Details

- {{item.text}}

Quick Details

-

Spindle Bore(mm):

-

350

-

Width of bed (mm):

-

40 mm

-

Spindle Motor Power(kW):

-

BT40

-

Travel (X Axis)(mm):

-

200 mm

-

Travel (Z Axis)(mm):

-

460 mm

-

Place of Origin:

-

China

-

Weight (KG):

-

4000

-

max diameter:

-

580

-

max working length:

-

380

-

x axis travel:

-

200

-

Z axis:

-

460

-

ATC tools:

-

24

-

Precision:

-

0.004mm

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

350

-

Max. Spindle Speed (r.p.m):

-

50 r.p.m

-

Spindle Bore(mm):

-

350

-

Width of bed (mm):

-

40 mm

-

Spindle Motor Power(kW):

-

BT40

-

Travel (X Axis)(mm):

-

200 mm

-

Travel (Z Axis)(mm):

-

460 mm

-

Place of Origin:

-

China

-

Weight (KG):

-

4000

-

max diameter:

-

580

-

max working length:

-

380

-

x axis travel:

-

200

-

Z axis:

-

460

-

ATC tools:

-

24

-

Precision:

-

0.004mm

Suntec vertical automatically cnc metal cnc lathe for metal drilling milling center

1. The machine components are integrated into a strong foundation. The low center of gravity of the machine body and the 30° bed saddle design provide an extremely stable base for the machine head saddle, turret and tailstock.

2. The base adopts a 30° inclined bed rail and a low center of gravity structure, with a newly designed servo turret (optional), not only can achieve fast feed and high-speed cutting; and the milling horsepower has been greatly improved, providing users with a wider range of processing application range.

3. Equipped with a new high-tech servo positioning turret, the tool change is fast and the positioning is accurate, and the processing efficiency is greatly improved.

Spindle 4,500rpm The high-torque spindle is driven by a wide-area spindle motor with a high horsepower output of 15KW, which can easily overcome various heavy cutting requirements.

4. The X and Z axes are designed with high-rigidity linear rails. The screw rod adopts C3-grade screw rod and pre-stretched assembly process to strengthen the axial rigidity and provide the rigid foundation required for heavy cutting.

5. When processing long workpieces, the standard hydraulic tailstock with movable thimble provides enough support to maintain the processing accuracy of the whole stroke. The tailstock movement is connected to the bed saddle with a hydraulic movable puller block, which is driven to the required position by the bed saddle.

6. The special high-performance PK belt drive spindle system can make maintenance easier and reduce the influence of heat generated by the motor on the spindle accuracy.

7. The fully covered protective sheet metal isolates turning iron chips and coolant in the machine tool, providing you with a safe and clean working environment.

|

type |

units |

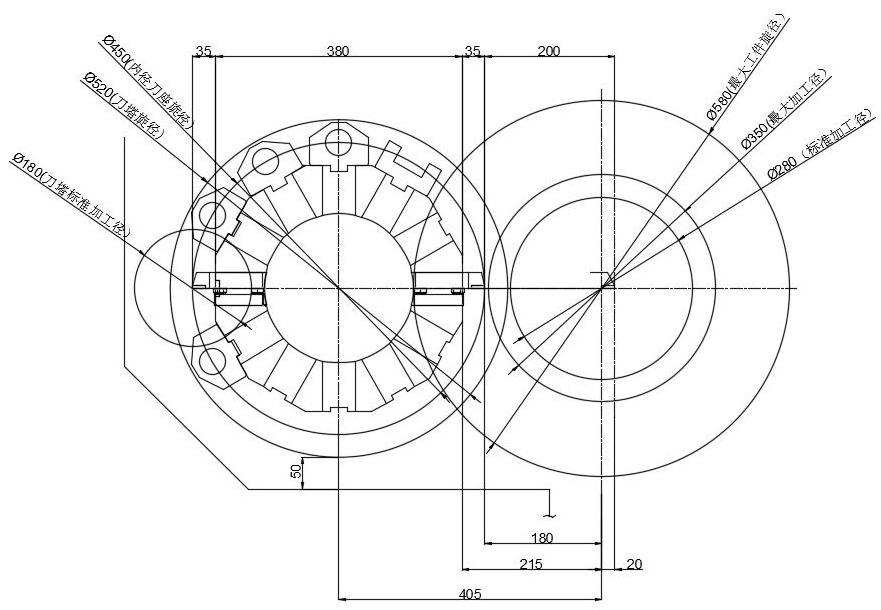

TC350 |

|

process capability |

||

|

Maximum rotation diameter of bed |

mm |

Φ580 |

|

Maximum rotation diameter of bed saddle |

mm |

Φ350 |

|

maximum machining diameter |

mm |

Φ350 |

|

maximum machining length |

mm |

380 |

|

Bed angle |

degree |

30° |

|

journey |

||

|

|

mm |

200(180+20) |

|

|

mm |

445 |

|

principal axis |

|

|

|

speed of mainshaft (rpm) |

rpm |

45-3500 |

|

Spindle nose end |

type |

A2-6 |

|

Spindle through diameter (diameter) |

rpm |

Φ67(Φ79) |

|

Spindle front bearing aperture |

mm |

Φ100 |

|

Maximum bar diameter (selection) |

mm |

Φ52(Φ66) |

|

Oil pressure chuck diameter (selection) |

inch |

8(10) |

|

DOTA |

||

|

form |

type |

servo |

|

Capacity of the knife tower (optional) |

branch |

8(12) |

|

Square cutter |

mm |

25*25 |

|

Circular cutter |

mm |

Φ40 |

|

Tool changing time |

second |

0.6 |

|

Feed rate |

||

|

Two axes moving fast |

m/min |

30/30 |

|

Cutting feed rate |

mm/min |

1-10000 |

|

tail bed |

||

|

Diameter of core shaft (mm) |

mm |

Φ75 |

|

Thimble taper |

mm |

MT4 |

|

Core axis movement |

mm |

100 |

|

Tail seat stroke |

mm |

290 |

|

ac motor |

||

|

Main shaft motor (select) |

KW |

11/15(18.5) |

|

X/Y axis servo motor |

KW |

|

|

hydraulic pump |

KW |

0.745 |

|

Iron scraps conveyer motor |

KW |

0.2 |

|

cooling water pump |

KW |

0.96 |

|

precision |

||

|

positioning accuracy |

mm |

±0.004 |

|

repeat ability precision |

mm |

±0.003 |

|

The machine size |

||

|

Power demand |

KVA |

25 |

|

Mechanical dimensions (long * wide) |

mm |

3400*1800 |

|

Mechanical height |

mm |

1700 |

|

Maximum weight of machine |

kg |

3600 |

Workshop