- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hokang

-

Voltage:

-

220V,380V,440V,400V

-

Dimension(L*W*H):

-

1400*1400*2300

-

Marketing Type:

-

Hot Product

-

Weight (KG):

-

800 kg

-

Product name:

-

brick making machinery

-

Advantage:

-

High effective of machine, Low cost

-

Main equipment:

-

block machine

-

Specification:

-

can customized

-

Machine Type:

-

Semi Automatic Brick Block Making Machine

-

Block Type:

-

Hollow Concrete Brick Machine

-

Product Type:

-

Brick Production Equipment

-

Application:

-

Buliding Construction

-

After Warranty Service:

-

Lifelong Service

-

After-sales Service Provided:

-

Lifelong Service

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

Cement,Concrete,Sand,Crushed Stone

-

Production Capacity (Pieces/8 hours):

-

Other, 4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hokang

-

Voltage:

-

220V,380V,440V,400V

-

Dimension(L*W*H):

-

1400*1400*2300

-

Marketing Type:

-

Hot Product

-

Weight (KG):

-

800 kg

-

Product name:

-

brick making machinery

-

Advantage:

-

High effective of machine, Low cost

-

Main equipment:

-

block machine

-

Specification:

-

can customized

-

Machine Type:

-

Semi Automatic Brick Block Making Machine

-

Block Type:

-

Hollow Concrete Brick Machine

-

Product Type:

-

Brick Production Equipment

-

Application:

-

Buliding Construction

-

After Warranty Service:

-

Lifelong Service

-

After-sales Service Provided:

-

Lifelong Service

Products Overview

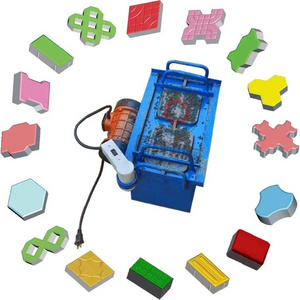

Small scale industrial concrete manual interlocking brick hollow concrete block making machine

Two Types of Brick Making Machines

There are two types of our brick making machines, one is normal type without hopper; the other is semi-automatic machine with hopper.

Without hopper

With hopper.

4-35B can be used with conveyor belts to realize semi-automatic operation, which is more convenient to use and saves manpower and time.

Video display:

Features of Small concrete brick making machine

1, The manual mud brick machine has the advantages of simple structure, compactness, convenient operation, convenient maintenance, small hardness, high output, less investment and quick effect.

2, The raw materials are abundant and can be seen everywhere. It is very convenient to invest and build factories.

3, Fast product forming, high density and high pressure

1, The manual mud brick machine has the advantages of simple structure, compactness, convenient operation, convenient maintenance, small hardness, high output, less investment and quick effect.

2, The raw materials are abundant and can be seen everywhere. It is very convenient to invest and build factories.

3, Fast product forming, high density and high pressure

4, One machine has multiple functions, and different molds can be replaced

The building block machine, through mould and by application of fly ash and other industrial waste, can produce all kinds of hollow block.solid block, which are widely used in the construction of municipal works, buildings, garden sand roads and its productivity is very high.

Specification

|

Model

|

4-35B

|

|

Dimensions

|

140*140*230cm

|

|

Pallet size

|

850*550*30cm

|

|

Total Weight

|

800kg

|

|

Molding time

|

35s

|

|

Standard brick specifications and output

|

240*53*115mm 10000-12000 pieces

|

|

Hollow brick specifications and output

|

390*190*190mm 2000-2400 pieces

|

|

Number of operators

|

1-2

|

|

Transfer method

|

Electric

|

|

Power

|

5.5kw

|

Our brick making machine supports customized service, if necessary, please provide the exact size of the block you need, block picture, capacity per 8h you want. Click on the picture below, our salesman will contact you.

Machine Structure

1,Usage and features

This machine can be constituted a simple production line with mixer.

2,Features

The small stationary concrete block making machine adopts both mechanical and electric methods meanwhile to complete its work. It is easy to operate the machine and do the maintainance.

This machine can be constituted a simple production line with mixer.

2,Features

The small stationary concrete block making machine adopts both mechanical and electric methods meanwhile to complete its work. It is easy to operate the machine and do the maintainance.

The block machine adopts the way of platform vibration to feed materials. Because of the vertical vibration, the block will be made at a high speed as well as in the form of high density.

3,Machine structure

The concrete block making machine is made up of the machine frame, lifting system, vibration system, mould assembly, electrical control and etc.

4,Machine frame

The frame of the host machine adopts dragon frame structure. It is made of the steel of the right temper so that the host machine is stable, vibration-proofing, and reliable.

5,Lifting system

The lifting system is compose of cycloid pin motor, reducer, lifting arm, hanging pin, positioning pin, and etc.

6,Vibration system

The vibration system of this machine can be divided into two parts. The down platform vibrator adopts two sets of high-speed attached vibration motor with the power of 3kw for each. The up vibrator adopts a high-speed attached vibration motor with the power of 1.5kw. While molding, both the down platform vibrator and the up vibrator vibrate at the same time, making the concrete firm and compressed.

3,Machine structure

The concrete block making machine is made up of the machine frame, lifting system, vibration system, mould assembly, electrical control and etc.

4,Machine frame

The frame of the host machine adopts dragon frame structure. It is made of the steel of the right temper so that the host machine is stable, vibration-proofing, and reliable.

5,Lifting system

The lifting system is compose of cycloid pin motor, reducer, lifting arm, hanging pin, positioning pin, and etc.

6,Vibration system

The vibration system of this machine can be divided into two parts. The down platform vibrator adopts two sets of high-speed attached vibration motor with the power of 3kw for each. The up vibrator adopts a high-speed attached vibration motor with the power of 1.5kw. While molding, both the down platform vibrator and the up vibrator vibrate at the same time, making the concrete firm and compressed.

Details Images

Travel column

Accurate positioning, mold balance and stability, increase block density

Lower mold box

Customized mold replacement according to customer requirements

Upper mold head

The pressure head moves longitudinally, which is convenient for feeding, maintenance and washing

Control cabinet

The control cabinet is simple in structure and easy to operate

Vibration motor

Durable, pure copper core vibration motor

Lift motor

The upper mold is driven by the chain, saving time and labor

Product Application

Block material:

Crushed stone powder, sand, stone, cement, can add a large amount of fly ash, slag, steel slag, coal gangue, ceramsite and various kinds of construstion wastes.

Product Application

Hot Searches