Introduction:

1.

Suitable for screen printing on round, oval, square, triangular and other shapes 'surface of containers (cosmetics,wine,beverage bottles, and general purpose containers).

2.

Adopt high precision imported servo turntable and full servo drive system. High printing speed, easy and fast debugging, stable and reliable quality.

3

.

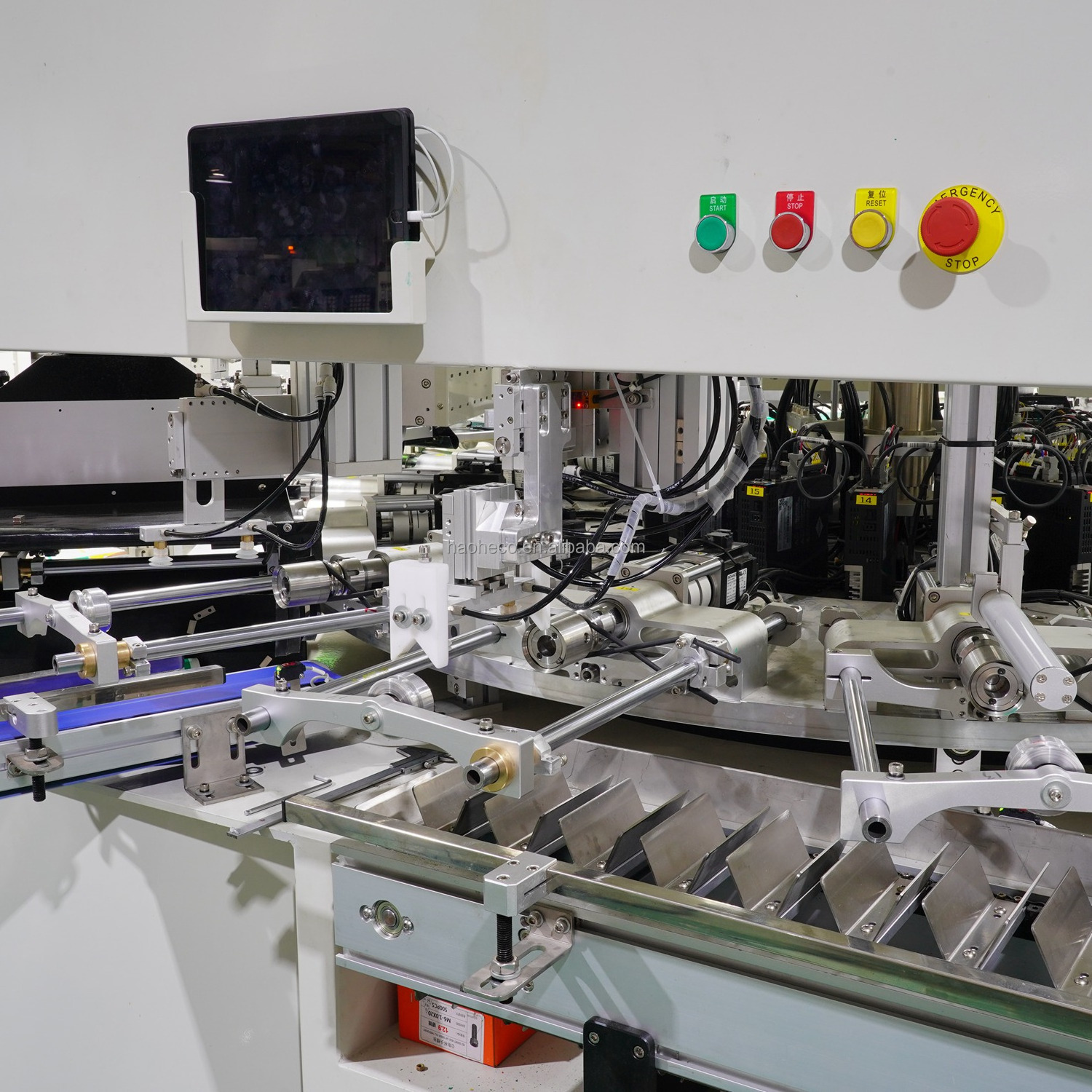

Germany BECKHOFF motion controller,and 10"ipad mobile touch screen.

4.

The 12-axis tube position holder is controlled and operated by absolute servo motor.

5.

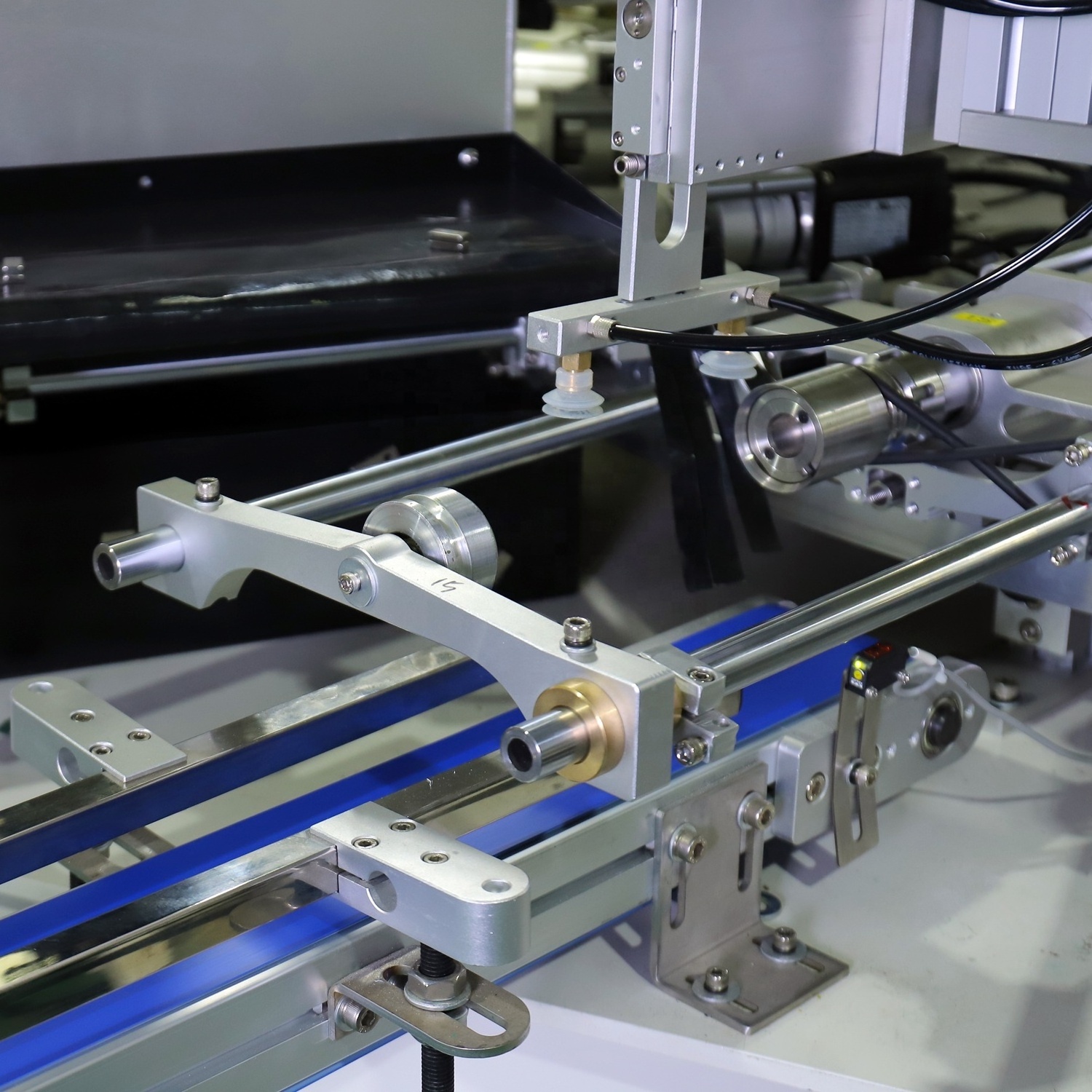

The main drive is controlled by high precision reducer with absolute value servo motor.

6.

Ball screws and guide rails all adopt international famous brands,which have higher precision and longer life.

7.

LED UV curing is also servo-driven.The curing time can be set arbitrarily according to the requirements of product printing,which greatly increases the adhesion of the ink.

8.

It has an independent vacuum system,and the anti-wear products can be made by vacuum suction.Effectively avoid product abrasion during the printing process,and ensures independent vacuum for more stable printing quality.

9. Pri

nting in the same color on round, oval,square,triangular, and other shapes' surface of container can be completed at one time.

10. Flame treating with servo drive can achieve arbitrary speed adjustment.

11. It can achieve multi-color overprinting and precise control of patterns based on product surface position, via bottle opening or pattern positioning point detection by laser sensor or CCD vision detection.

12. Simple debugging of replacement models without gears. Thus avoiding the inaccuracy of color registration after wear of the rack and pinion, and significantly save time on tuning.

13.

CCD post-print inspection system can also be configured,and leave space for subsequent additions.

·14. More reasonable design of the main structure and significant optimization over existing domestic machines make it achieve stable and efficient production.