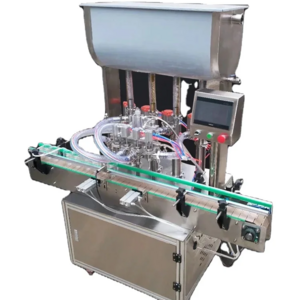

No-drip filing nozzles, which can protect the cylinder on the top being damaged by material.Easy to operate, no bottle no filling,

auto orientation detection.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 50HZ

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Ipanda

-

Dimension(L*W*H):

-

2400x1200x1700 mm

-

Weight (KG):

-

580

-

Product name:

-

Liquid Filling Machine

-

Material:

-

SUS304/316

-

Capacity:

-

2000-3000bph,customize

-

After-sale service:

-

Engineers available to service machinery overseas

-

Filling volume:

-

2ml-50ml customized

-

Filling material:

-

reagent,syrup,oral liquid etc.

-

Bottle type:

-

Galss Bottle,plastic bottle

-

Filling Accuracy:

-

99.9%

-

Advantage:

-

High Effiency

-

Air pressure:

-

0.4-0.6 MPa

Quick Details

-

Production Capacity:

-

40bpm

-

Automatic Grade:

-

Full Automatic

-

Driven Type:

-

Electric

-

Voltage:

-

220V 50HZ

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Ipanda

-

Dimension(L*W*H):

-

2400x1200x1700 mm

-

Weight (KG):

-

580

-

Product name:

-

Liquid Filling Machine

-

Material:

-

SUS304/316

-

Capacity:

-

2000-3000bph,customize

-

After-sale service:

-

Engineers available to service machinery overseas

-

Filling volume:

-

2ml-50ml customized

-

Filling material:

-

reagent,syrup,oral liquid etc.

-

Bottle type:

-

Galss Bottle,plastic bottle

-

Filling Accuracy:

-

99.9%

-

Advantage:

-

High Effiency

-

Air pressure:

-

0.4-0.6 MPa

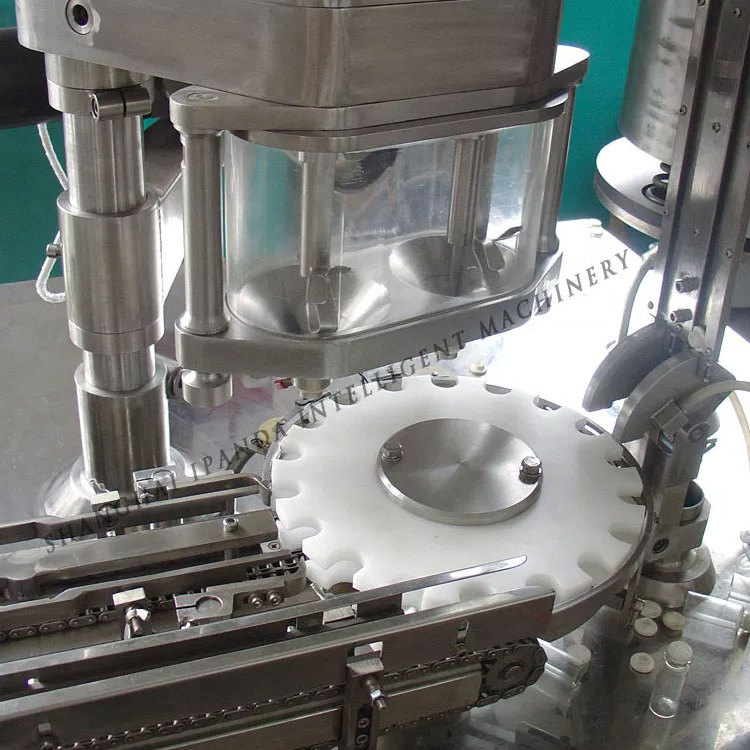

This machine is mainly used for automatic bottle unscrewing and capping (capping) of plastic bottle reagents. This machine adopts automatic bottle sorting, flat positioning upper mandrel, positioning gland, reasonable design; working table is protected by stainless steel material, and the whole machine meets GMP requirements. The transmission of this machine adopts mechanical transmission, the transmission is accurate and stable, there is no air source pollution and there are errors in the coordination of various mechanisms. When working, the noise is low, the loss is low, the work is stable, and the output is stable. It is especially suitable for small and medium batch production.

Main Features

* All electrical components arewell-known brands.

* Disc positioning filling, which is stable and reliable.

* Frequency conversion controlcan adjust production speed arbitrarily.

* Automatic stop to achieve no bottle no filling, no bottle no capping. All electrical components arewell-known brands.

* Disc positioning filling, which is stable and reliable.

* High-precision cam indexer controlto reach precise positioning.

* It is made of SUS304 or316L stainless steel, which meets GMP requirements.

* Man-machine interface settingwith PLC control has intuitive and convenient operation

* Accurate loadingand automatic counting.

* Frequency conversion controlcan adjust production speed arbitrarily.

* Automatic stop to achieve no bottle no filling, no bottle no capping.

* Disc positioning filling, which is stable and reliable.

* Frequency conversion controlcan adjust production speed arbitrarily.

* Automatic stop to achieve no bottle no filling, no bottle no capping. All electrical components arewell-known brands.

* Disc positioning filling, which is stable and reliable.

* High-precision cam indexer controlto reach precise positioning.

* It is made of SUS304 or316L stainless steel, which meets GMP requirements.

* Man-machine interface settingwith PLC control has intuitive and convenient operation

* Accurate loadingand automatic counting.

* Frequency conversion controlcan adjust production speed arbitrarily.

* Automatic stop to achieve no bottle no filling, no bottle no capping.

Product Paramenters

|

Accuracy

|

±2%

|

|

Speed

|

70-90 bottles/min

|

|

Upper cover mode

|

Manipulator the upper cover

|

|

Voltage

|

220V/50Hz

|

|

Power

|

4 KW

|

|

Dimensions

|

2400mm×1200mm×1700mm

|

|

Weight

|

580kg

|

Details Images

sealing caps tight and no hurt to caps,capping nozzles is customized according to the caps

It's customized according to your bottles and caps.

Related Products

Before order service

We will according to your requirement make details quotation for you.

We can send you some our machine running video similar to your product.

If you come to china,we can pick you up from airport or station near our city.

After order service

We will start to make machine,and take some picture by 10 days of our production process .

Our engineer can design the layout according to your requirement.

We will supply commission service if customer need.

Our engineer can design the layout according to your requirement.

We will supply commission service if customer need.

After-sales service

We will testing machine ,and take some video and picture to you if u not come to china inspect machine.

After testing machine we will packing machine ,and delievery container on time.

We can send our engineer to you country help you install and testing machine.we can training you technical staff free until they can running machine independent.

Our company will give you all machine with 1 years guaranteen.In 1years you can get all spare parts free from us.we can send you by express.

After testing machine we will packing machine ,and delievery container on time.

We can send our engineer to you country help you install and testing machine.we can training you technical staff free until they can running machine independent.

Our company will give you all machine with 1 years guaranteen.In 1years you can get all spare parts free from us.we can send you by express.

Hot Searches