JINNTA, a Shanxi Construction Machinery Co., Ltd trade mark, is a Shanxi CIG Group member. Professional manufacturer of Tower cranes, Construction Hoists. Member of China Construction Machinery Industry Association Top 10 tower crane companies in China.

- Product Details

- {{item.text}}

Quick Details

-

Rated Lifting Moment:

-

125KN m

-

Span:

-

61.3M

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

JINNTA

-

Weight (KG):

-

6666 kg

Quick Details

-

Rated Loading Capacity:

-

Other

-

Max. Lifting Height:

-

4.5m

-

Application:

-

Construction

-

Rated Lifting Moment:

-

125KN m

-

Span:

-

61.3M

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

JINNTA

-

Weight (KG):

-

6666 kg

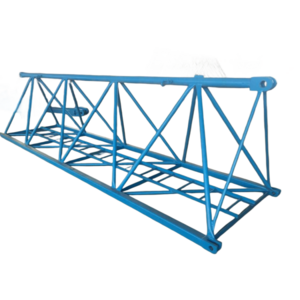

JINNTA Official 26 ton Flat Top tower crane

STP125(C6015P-8)

Lifting Machinery China Best on sale

JINNTA,

Covers an area of 300.31 acres.

The annual production capacity is 1,000 tower cranes, 1,500 construction elevators, and 15,000 linear meters of attached lifting scaffolding. The company has a complete quality assurance system for special equipment, has A-level qualifications for tower crane manufacturing,installation,maintenance and transformation. First-class construction equipment manufacturing base in China.

livery upgrade

①Using green powder coating technology, the coating quality is industry-leading

②The intelligent coating line integrates a fully automatic bath liquid-adding system, a catalytic far-infrared heating system and an online monitoring system

③The appearance of the product is good, and the ageing resistance test and salt spray resistance test both reach 1200h

Good safety performance

①Using frequency conversion speed regulation, energy saving, high efficiency and intelligence

②The electronic control system intelligently detects and protects the anti-slip hook

③ Equipped with a safety monitoring system, intelligent and sensitive

④It has the functions of anti-tilting, anti-crash, anti-overload, anti-overspeed, anti-collision of group towers, and anti-collision of restricted areas

superior performance

①The boom adopts a 5-meter-step variable boom method, which can realize various combinations of boom lengths.

②The series of tower cranes adopt a modular design concept, and the parts are highly versatile.

③Product design with a high safety factor, high rigidity and small deformation.

humanized design

①The quick-installation structure is adopted, which is convenient to disassemble and assemble, saves time and effort, and can realize the whole machine with 4 cranes and a half-day vertical tower ② Add multiple working platforms for easy installation,disassembly and commissioning operations to improve operational safety ③Details of product components are polished to improve the reliability of the tower crane and reduce the failure rate ④ Ladders and railings are fully galvanized, platforms and walkways are designed with aluminum alloy anti-slip, anti-corrosion and anti-rust within the life cycle ⑤ Equipped with an inclined ladder and a large platform, which can effectively prevent falling and ensure life safety ⑥The driver's cab platform and the balance arm platform adopt the hanging type, which is convenient and quick to install ⑦The driver's cab is molded at one time,automotive-grade spot welding process, electrophoresis process, anti-corrosion throughout the life,and the space is increased by20%

Good handling performance

① Equipped with luffing anti-sway function to ensure the anti-sway and precise positioning when the hanging object is walking and stopping

②Millimeter-level fast positioning, minimum 5mm/s, instant response to jog

③Light load automatic speed up, improve work efficiency ④The three major mechanisms all adopt frequency conversion control, with smooth starting and braking and long service life

⑤The anti-car function solves industry pain points such as "stop rebound, slow jog response, and difficulty in parking

against wind"

against wind"

⑥Real-time remote monitoring and recording of tower crane hoisting data and violation data

⑦Face recognition, remote locking, strict management of equipment

Hot Searches