- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Shenglin

-

Liquid Flow Rate:

-

none

-

Maximum Working Pressure:

-

none

-

Weight:

-

4 KG

-

Dimension(L*W*H):

-

customize

-

Working Temperature Range:

-

-30℃-99℃

-

Type:

-

plate fin heat exchanger, Intercooler, radiator

-

Refrigerant:

-

R22, R134a, R407c, R290, R404A

-

Material:

-

aluminum

-

Usage:

-

Refrigerator, air compressor, commercial and industrial refrigeration

-

Cooling capacity:

-

customized

-

Packing:

-

wooden

-

Fin type:

-

Plain Fin, Perforated Fin, Wavy Fin, Louvered Fin, Serrated Fin..

-

Fin space:

-

1.4/1.7/2.0/2.5/3.0

Quick Details

-

Structure:

-

Plate Heat Exchanger

-

Voltage:

-

220

-

Core Components:

-

copper

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Shenglin

-

Liquid Flow Rate:

-

none

-

Maximum Working Pressure:

-

none

-

Weight:

-

4 KG

-

Dimension(L*W*H):

-

customize

-

Working Temperature Range:

-

-30℃-99℃

-

Type:

-

plate fin heat exchanger, Intercooler, radiator

-

Refrigerant:

-

R22, R134a, R407c, R290, R404A

-

Material:

-

aluminum

-

Usage:

-

Refrigerator, air compressor, commercial and industrial refrigeration

-

Cooling capacity:

-

customized

-

Packing:

-

wooden

-

Fin type:

-

Plain Fin, Perforated Fin, Wavy Fin, Louvered Fin, Serrated Fin..

-

Fin space:

-

1.4/1.7/2.0/2.5/3.0

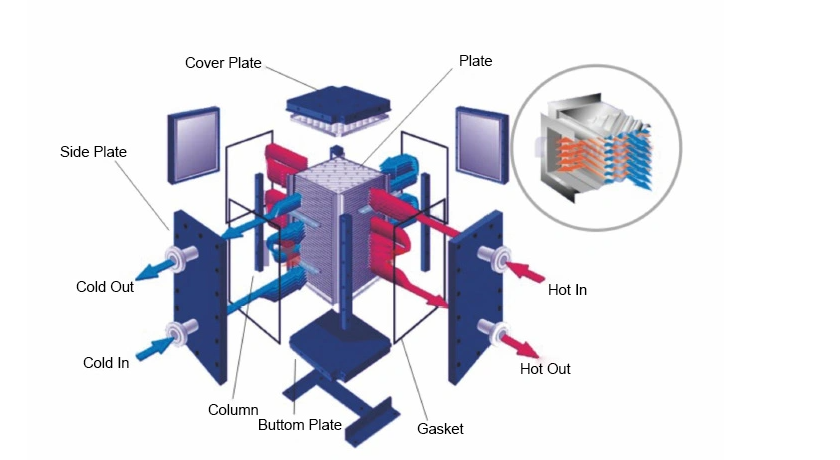

Welded Plate Heat Exchanger

Brief Introduction

Brief Introduction

The laser frame plate heat exchanger combines the advantages of plate heat exchangers and shell and tube heat exchangers, maintaining the advantages of traditional plate heat exchangers such as high heat transfer efficiency, compact structure, high temperature resistance, good sealing performance, safety and reliability, and can also be used under higher pressure and temperature conditions. Suitable for steam condensation and liquid liquid heat exchange, especially suitable for the heat exchange needs of special media in industries such as power, petrochemical, coking, metallurgical, refrigeration, pulp and paper industry, etc.

The reasonable setting of the process ensures the reasonable matching of the heat transfer efficiency and Friction loss of the equipment. The shell adopts a Hexahedron detachable structure, which can also meet the process requirements of mechanical cleaning and chemical cleaning inside the equipment.

Models

|

Parameter Table of Laser Welded Plate Heat Exchanger |

||||||

|

Model |

Overall Dimension(mm) |

Maximum Assembly area

|

Connection Diameter |

Standard Pressure Range |

||

|

Max length |

Width |

Height |

||||

|

HU-06Y |

820 |

600 |

1175 |

10 |

DN150 |

≤3.2MPa |

|

HU-18Y |

1050 |

720 |

1285 |

35 |

DN200 |

|

|

HU-30Y |

750 |

735 |

1350 |

21 |

DN250 |

|

|

HU-30Y |

1250 |

720 |

1350 |

62 |

DN250 |

|

|

HU-50Y |

950 |

910 |

2000 |

78 |

DN350 |

|

|

HU-60Y |

1680 |

860 |

1450 |

125 |

DN350 |

|

|

HU-75Y |

1260 |

1220 |

2860 |

295 |

DN500 |

≤3.0MPa |

|

HU-90Y |

1780 |

1160 |

2250 |

300 |

DN500 |

|

|

HU-110Y |

2080 |

1160 |

2000 |

300 |

DN500 |

|

|

HU-130Y |

2380 |

1160 |

1700 |

300 |

DN500 |

|

|

Standard temperature range:-20℃ to 300℃ |

||||||

Compared to plate and frame heat exchangers

- High temperature resistance, up to 300 ℃.

- High pressure resistance, up to 4.0MPa

- Corrosion resistant, can be used in situations where the medium corrodes the sealing gasket.

- Production processes with high safety requirements for flammable, explosive, toxic media, and the environment. The temperature and medium resistance of the plate and frame heat exchanger completely depend on the rubber pad, which also limits the application range of the plate and frame heat exchanger; the laser welded heat exchanger is directly welded from plate to plate, without rubber pad, and has a wide application range)

|

Material |

Operating Temperature range |

Operating Conditions |

|

Dingqing rubber gasket |

≤135℃ |

Resistant to non-polar media such as minerals, animals, and vegetable oils. |

|

Oxidized nitrile rubber gasket |

-5~-150℃ |

Sulfur resistant crude oil, mixed medium containing H25, non polar medium such as high-temperature edible oil. |

|

EPDM gasket |

≤180℃ |

Resistant to hot water, steam, edible beverages, and high-temperature sterilization of milk. |

|

Solvent based EPDM gasket |

-20~-150℃ |

Various good solvents such as polar solvents. |

|

Universal fluorine rubber gasket |

≤180℃ |

Non polar mineral oil, lubricating oil, and other alcohol-containing fuels. |

|

Special fluorine rubber gasket |

30~-130℃ |

High concentration sulfuric acid and other inorganic Oxyacid. |

- There are no corner holes, which increases the effective heat transfer area.

Compared to plate and frame heat exchangers

Laser welding heat exchanger extends the application range of gasket heat exchanger, and has the advantages of high temperature resistance, high pressure, corrosion and high heat transfer efficiency. It can replace traditional shell and tube heat exchangers.

- Compact structure, low initial investment cost, and small footprint. The same heat exchange area requires an area equivalent to 1/3 of the shell and tube.

Application

- Oil refining and mining industry.

- Petrochemical

- Oil & Gas

- Energy Power

- Metallurgy

- Biomedical

High heat transfer efficiency, turbulent state achieves small temperature difference heat transfer, small heat transfer area, low fouling degree, and small liquid retention.

- Cleaning is relatively easy. Cleaning the tube shell is quite difficult, and sometimes it is necessary to extract the tube bundle. The fully welded detachable cover plate flushes the internal core area.

Advantages:

1. Good quality

2. Factory direct sales

3. Reasonable and competitive price

4. Safe and quick delivery

5. We could do it according to your drawing and enquirement.

Product picture reference