- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

6500*5200*2250mm

-

Motor Power (kW):

-

40

-

Model Number:

-

ES23

-

Weight (T):

-

14

-

Marketing Type:

-

Hot Product 2023

Quick Details

-

Place of Origin:

-

Jiangsu

-

Brand Name:

-

Tailift

-

Voltage:

-

#

-

Dimension(L*W*H):

-

6500*5200*2250mm

-

Motor Power (kW):

-

40

-

Model Number:

-

ES23

-

Weight (T):

-

14

-

Marketing Type:

-

Hot Product 2023

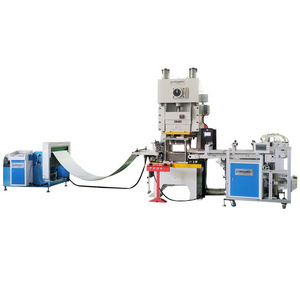

ES SERISES

Tailift's latest innovation, ES23/ES23X, AC Servo drive and numerical control technology. Featuredwith high speed, high precision, energy saving, and low noise.Equipped with over-load protection, ES23 is an effective implement for thinner sheet metal.ES23/ES23X combined with processing abilities of, punching, forming, roller cutting and tapping, anal-in-one machine. The integration assembly reduces floor space requirements effectively.Low electricity consumption, energy-saving, eliminating the hydraulic . This ECO friendly product isthe major milestone form Tailift's RAD.

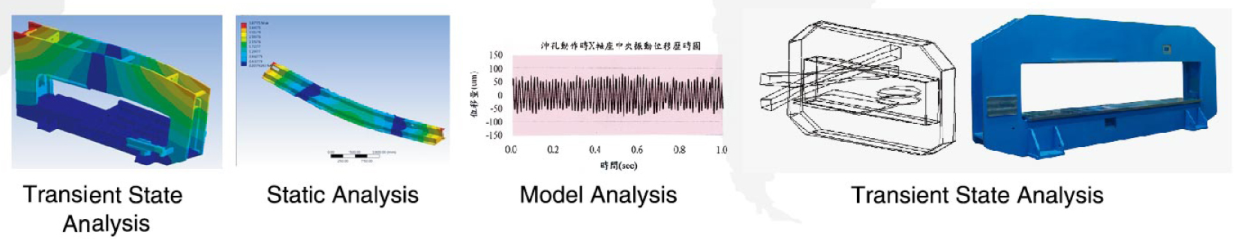

CLOSED O SHAPE FRAME STRUCTURE

The closed O shape frame structure is analyzed by the "Finite Element Analysis" software to simulate stress /strain conditions to enable the optimal structure design .

HIGH TENSILE STRENGTH STEEL CONSTRUCTION

The machine frame is welded by high tensile strength steel , which is subject to high tensile strength tests , normalization treatment and vibration stress relief so as to ensure the machine assembling accuracy.

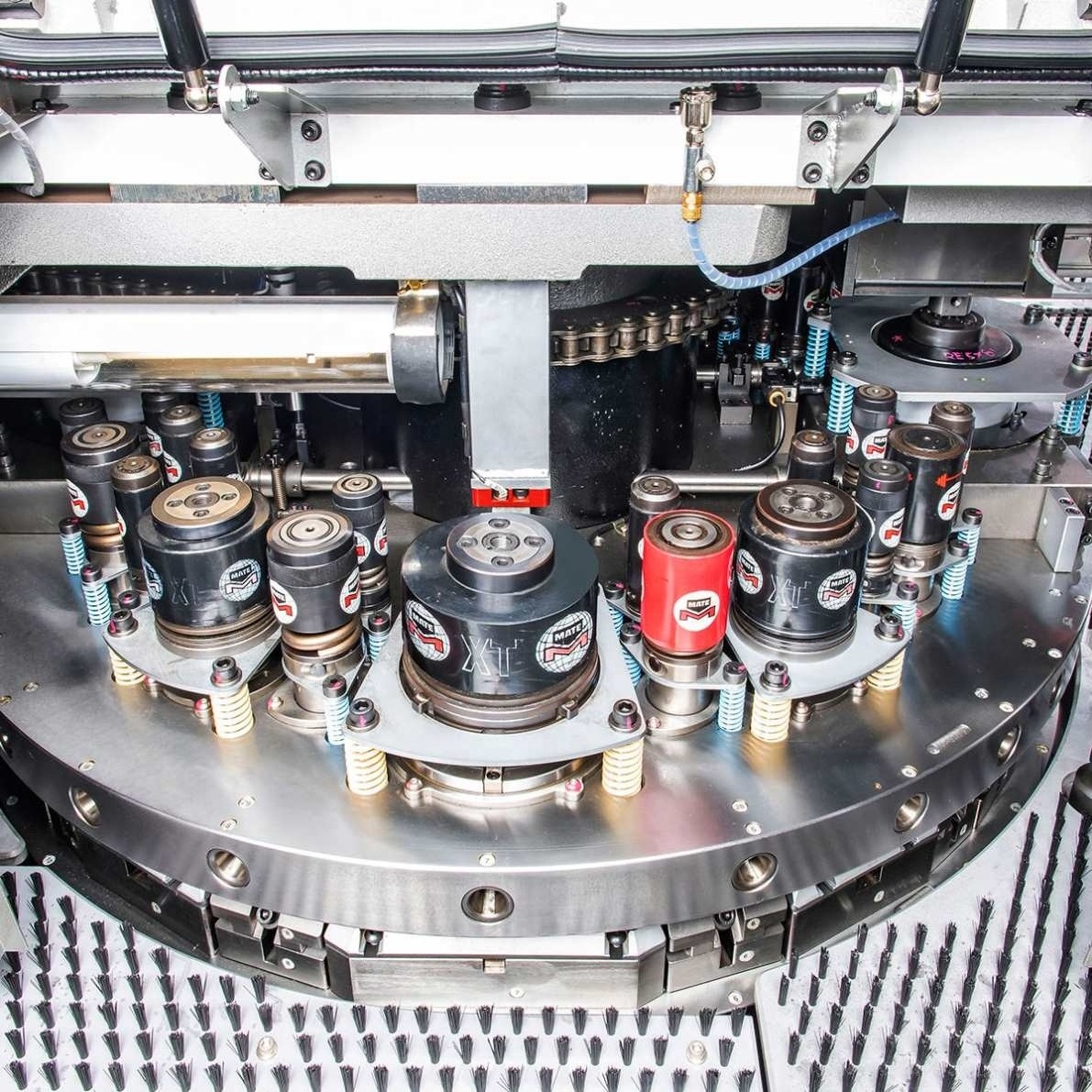

REPLACEABLE STATION BUSHING

Hardened steel bushings for all tool stations for high precision and durability , Easily replaceable when tool station is damaged.

AC SERVO ELECTRIC SYSTEM

ES23/ES23X employs high level AC servo motor in combination with theuse of crank type connecting rod without flywheel, leading to higheraccuracy and a low noise working environment. In punching operation,its average power consumption is only one-half of comparable hydraulicmodels and without need of hydraulic fluid as well as no environmentalpollution problem. Travel and speed can be set according to programsso as to achieve the optimal machining conditions.

MOVABLE RAM

Movable ram has overload protection , combined with a two circular track stations , making operation more flexible .

SECURITY LIGHT

Working status light, real-time

indicator of the current situation

of each processing in machine

indicator of the current situation

of each processing in machine

SHEET DISTORTION SENSOR

The sensor provides automatic detection for sheet distortion . once the sheet distortion occurs , the machine stops automatically to avoid damage to the machine and tools .

REPOSITIONING Cylinder

The repositioning cylinder is controlled by cnc programs to achieve high speed and accurate repositioning motions and ensures high machining accuracy .

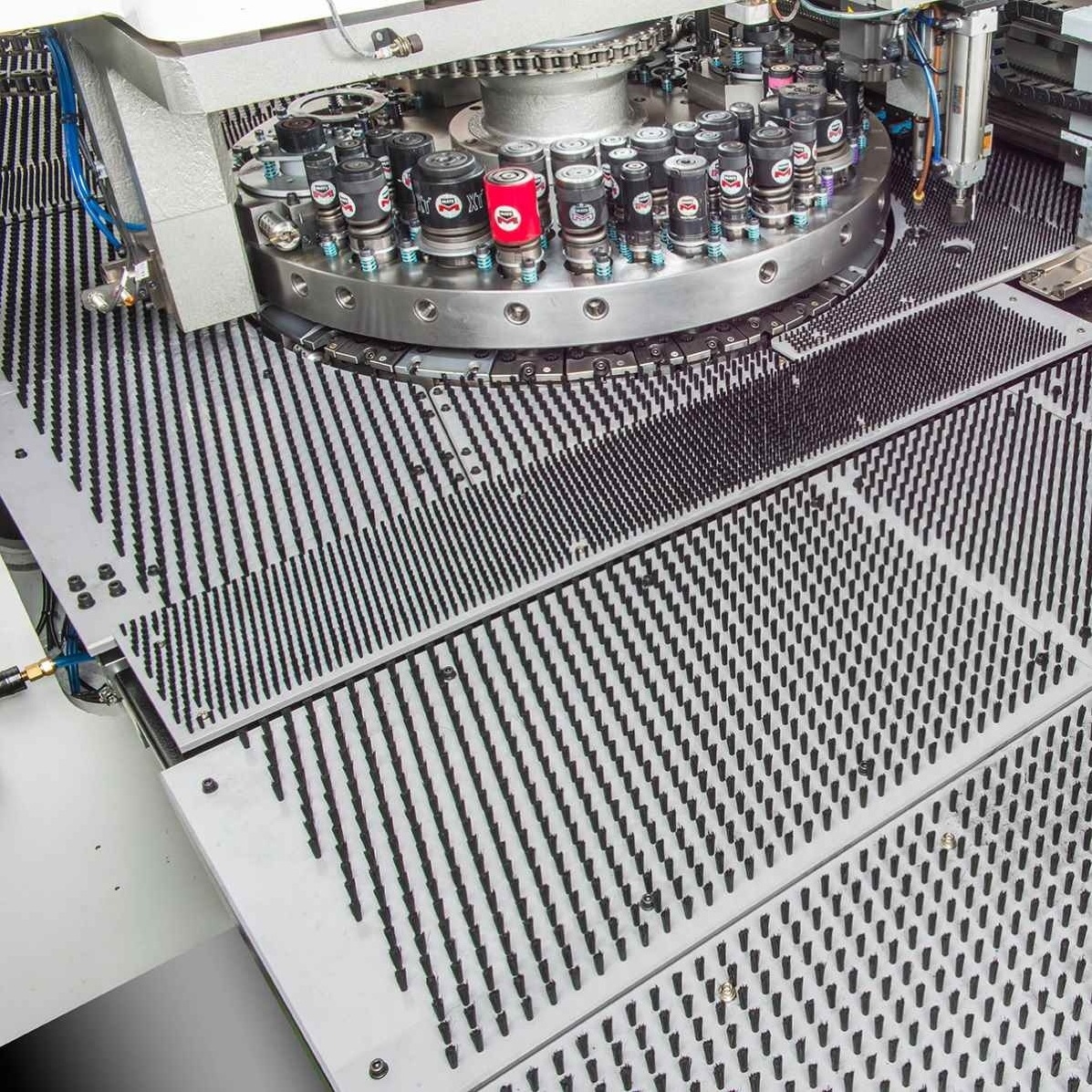

LARGE BRUSH TABLE

Provide noise reduction during operation and prevents the sheet from scratching

PATENTED LINEAR GUIDE OF CLAMP

Transmit by linear guide ,High rigidity , smooth and sleek movement ,enhance anti-toque abilities , Alone with sheet escape detector ,improve operation safety.

BLOCK LOWERING DEVICE

The block raised only when repositioning , In normal condition , the block positions itself under the brush to prevent sheet scratching due to a contact with the block.

DIE HOLDER BRUSH

Die holders are with replaceable brush for reducing scratches .

SUPPORTTING BALL SET

The supporting ball set makes sheet loading and unloading effortless and quick .

ANTI-VIBRATION FOOT MOUNTS

With the use of anti-virbation foot mounts, reduce the impact on the ball screw caused by frenquent acceleration /deceleration on X,Y -axis can be effectively cushioned.

FANUC CONTROLLER

RM series is equpped with FANUC OI-PD controller ,designed specifically for punch press with all new control panel design provides easy operation control.

CAD /CAM SOFTWARE

The windows operation displays enable the operator to learn in a short time .also machining editing is simplified.

AUTOMATIC TOOL LUBRICATION SYSTEM

The lubrication system is a program controlled oil mist system , which provides cleaning , cooling, which lubrication to tools , that help to upgrade machine quality and extend tool life as well .

TAPPING SYSTEM (OPTIONAL )

High-speed dual servo tapping system.Single-hole tapping within 1~2 seconds. Available for M3 to M6 Metric/lmperial system. With

quick-release tool unit and auto lubrication.

quick-release tool unit and auto lubrication.

|

ITEM

|

UNIT

|

ES23

|

ES23X

|

REMARKS

|

|

PUNCHING CAPACITY

|

TON

|

30

|

30

|

|

|

X TRAVERSE LENGTH

|

MM

|

2490±10

|

2490±10

|

|

|

Y TRAVERSE LENGTH

|

MM

|

1250±10

|

1250±10

|

|

|

MAX SHEET SIZE

|

MM

|

1250x4980

|

1250x4980

|

|

|

MAX SHEET THICKNESS

|

MM

|

3

|

3

|

|

|

MAX MASS OF MATERIAL

|

KGS

|

70

|

70

|

|

|

X AXIS TRAVERSE SPEED

|

M/MIN

|

80

|

80

|

|

|

Y AXIS TRAVERSE SPEED

|

M/MIN

|

70

|

70

|

|

|

MAX TRAVERSE SPEED

|

M/MIN

|

105

|

105

|

|

|

PUNCHING SPEED AT 25MM PICTCH

|

HITS/MIN

|

370

|

370

|

|

|

NIBBLING SPEED (STROKE LENTH 4MM ,PITCH 1MM)

|

HITS/MIN

|

600

|

600

|

|

|

TOOL TYPE

|

|

THICK TURRET

|

THICK TURRET

|

|

|

MAX PUNCHING DIAMETER

|

MM

|

88.9

|

88.9

|

|

|

NUMBER OF TOOL STATIONS

|

|

34

|

48/57

|

|

|

NUMBER OF AUTO INDEX STATIONS

|

PCS(TYPE)

|

2B

|

48 4(2B+2C)

57 3(2B+1C)

|

|

|

TURRET ROTATING SPEED

|

RPM

|

33

|

33

|

|

|

AUTO INDEX ROTATING SPEED

|

RPM

|

100

|

100

|

|

|

RAM STROKE DISTANCE

|

MM

|

31

|

31

|

|

|

WORKING TABLE

|

|

BRUSH

|

BALL+BRUSH

|

|

|

SUPPORTING BALL SET

|

|

STANDARD

|

STANDARD

|

|

|

NUMBER OFF SHEET CLAMPS

|

PCS

|

3

|

3

|

|

|

POWER SUPPLY

|

KVA

|

40

|

40

|

|

|

AIR SUPPLY

|

NL/MIN

|

250

|

250

|

|

|

AIR PRESSURE

|

BAR

|

5

|

5

|

|

|

DIMENSION(L x W x H)

|

MM

|

5105X4690X2110

|

5105X4740X2110

|

|

|

WEIGHT(approx.)

|

KGS

|

14000

|

16000

|

|

|

CONTROL CABINET DIMENSION

|

|

2150X700X2000

|

2150X700X2000

|

|

|

CNC CONTROLLER

|

|

FANUC OI-PF

|

FANUC OI-PF

|

|

|

NUMBER OF CONTROLLABLE AXIS

|

AXIS

|

4+1

|

4+1

|

|

|

MEMORY CAPACITY

|

KB

|

512

|

512

|

|

|

SERIAL INTERFACE

|

|

RS232/RJ45/PCMCM/USB

|

RS232/RJ45/PCMCM/USB

|

|

|

ACCURACY

|

MM

|

±0.05

|

±0.05

|

|

Case Presentation

Tailift Group was established more than 50 years ago in 1973. Eric Lin, a second-generation CEO, leads Tailift’s business departments.

Tailift’s products include a range of sheet metal facilities, such as laser-cutting machines, CNC turret punch presses, CNC sheet metal shearing machines and radial drills, and oolong tea manufacturing machines. As of today, Tailift acquired more than 5,000 clients domestically and overseas. Tailift is known as the largest and most comprehensive factory for making sheet metal processing equipment in Taiwan.

Choose Tailift Group, Make Life More Blissful

Memorabilia

The Chairman Mr. Steve Lin who majored in the faculty of logging came from a rural family, built the career map of Tailift Group by relying on his tough will and endless curiosity.

As a student, Mr. Steve Lin gained much more experience in the research of dismantling machines at intern factory school. And after leaving the army, he began to operate a machinery processing plant at his family’s Sanheyuan (tri-enclosed courtyard) in Daya, Taichung County, Taiwan. And then began to produce an unpopular and less competitive radial drilling machine into the machinery market.

Our team

Over the past 40 years, our employees have been one of our important assets. The average service experience of all departments is more than 15 years. Our production team implements TPS management and establishes a TPS culture to ensure the stability of product quality and precision. Members of Tailift are like one big family with simple culture. Our team is committed to growing with our customers and moving to the future.

Sustainability

With more than 45 years of cultivating localization in Taiwan, Tailift grows along with the development of Taiwan's machinery industry. With our unique technology and entrepreneurial spirit, Tailift has created a scale of nearly 10 billion annual revenues and has become a world-renowned brand. Tailift brand will be enjoying worldwide reputation, and the world will be glad to catch sight of Taiwan. The ultimate processing, the best quality, is the professional persistence that Tailift Group always pursues.

Hot Searches