- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Tobee

-

Model Number:

-

1.5x1C-HH

-

Place of Origin:

-

China

-

Horsepower:

-

Max.30 kw

-

Outlet Size:

-

1 inch

-

motor:

-

Electric

-

Contact info:

-

Sales3(at)tobeepump.com

-

Pump Model:

-

1.5x1C-HH

-

Capacity:

-

16.2-34.2 m3/h

-

Inlet:

-

1.5 inch

-

Color:

-

Blue

-

Speed:

-

1400-2200 rpm

-

Handling solids:

-

16 mm

-

Head:

-

25-92 m

-

Materials:

-

A05, A07, A12, A49, A51, A61 etc

-

Website:

-

www.tobeepump.com

Quick Details

-

Application:

-

Mining industry, Iron Ore Dressing Plant, Copper Concentration Plant, Molybdenum Concentration Plant, Potash Fertilizer Plant, Other Mineral Processing Plants, Alumina Industry, Coal Washery, Power Plant, Sand Excavation, Building Material Industry, Chemical Industry

-

Pressure:

-

High Pressure

-

Voltage:

-

220v/380v/440v

-

Brand Name:

-

Tobee

-

Model Number:

-

1.5x1C-HH

-

Place of Origin:

-

China

-

Horsepower:

-

Max.30 kw

-

Outlet Size:

-

1 inch

-

motor:

-

Electric

-

Contact info:

-

Sales3(at)tobeepump.com

-

Pump Model:

-

1.5x1C-HH

-

Capacity:

-

16.2-34.2 m3/h

-

Inlet:

-

1.5 inch

-

Color:

-

Blue

-

Speed:

-

1400-2200 rpm

-

Handling solids:

-

16 mm

-

Head:

-

25-92 m

-

Materials:

-

A05, A07, A12, A49, A51, A61 etc

-

Website:

-

www.tobeepump.com

Pump Descriptions

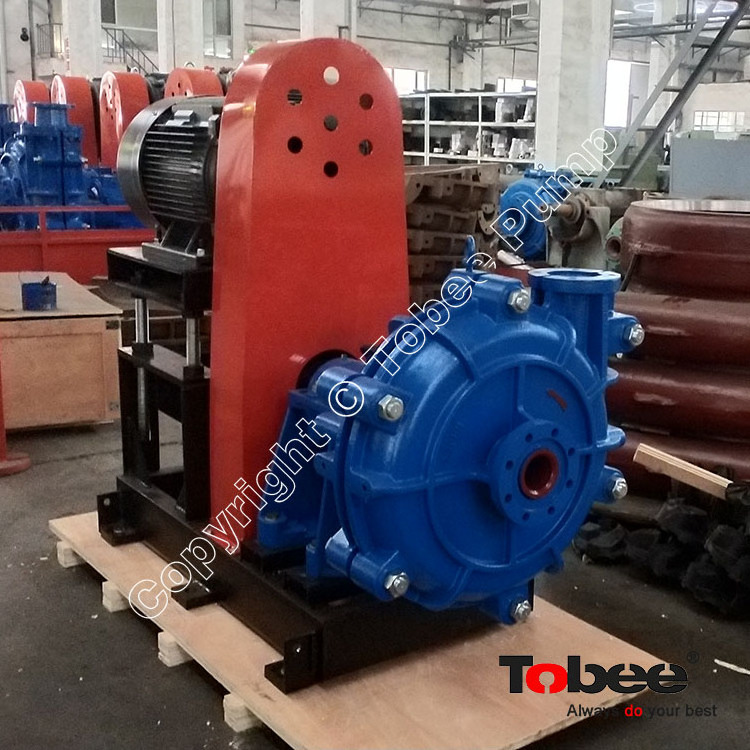

1.5x1C-HH High Head Slurry Pump

Tobee®

1.5/1C-HH High Head Slurry Pump were designed to produce high heads per stage at high pressures, commonly used for long distance transport lines, the 1.5x1 HH pump can often satisfy application duties with a single pump where others require multiple pumps, which is widely used to transport corrosive and abrasive and high concentration slurries in mining, sand, lead and various other industries including electric utilities, copper, oil shale, agriculture, etc. 1.5/1C-HH slurry pumps are equivalent to world’s standard HH series slurry pumps.

1.5x1C-HH Slurry Pump Specifications

|

Size

|

1.5" x 1"

|

|

Capacity

|

16.2-34.2 m3/h

|

|

Head

|

25-92 m

|

|

Speed

|

1400-2200 rpm

|

|

NPSHr

|

2-5.5 m

|

|

Eff.

|

20%

|

|

Power

|

Max.30 kw

|

|

Handling solids

|

16 mm

|

|

Materials

|

A05, A07, A12, A49, A51, A61 etc

|

1.5x1C-HH High Head Slurry Pump Features

√ Ductile iron fully lined casing provides durability, strength and long service life.

√ Multi-stage high pressure operation to 750 psi.

√ Heavy duty construction with through-bolt design provides ease of maintenance and minimal downtime.

√ Large diameter, slow turning, high efficiency impellers designed to achieve maximum wear life and low operating costs.

√ Large, open internal passages designed to maximize wear life and lower operating costs.

√ Thick elastomer and alloy liners provide superior corrosion resistance and maximum wear life.

√ Full flush gland, low flow, and dry running centrifugal seals reduce flush water usage minimizing pump operating costs.

√ Multi-stage high pressure operation to 750 psi.

√ Heavy duty construction with through-bolt design provides ease of maintenance and minimal downtime.

√ Large diameter, slow turning, high efficiency impellers designed to achieve maximum wear life and low operating costs.

√ Large, open internal passages designed to maximize wear life and lower operating costs.

√ Thick elastomer and alloy liners provide superior corrosion resistance and maximum wear life.

√ Full flush gland, low flow, and dry running centrifugal seals reduce flush water usage minimizing pump operating costs.

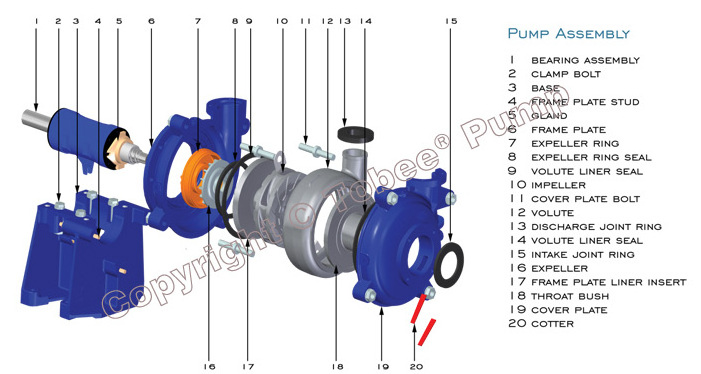

Tobee® HH High Head Slurry Pump Structure Chart

Sealing Arrangements

Packing Seal

As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available.

Centrifugal Seal - Expeller

The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry.

Mechanical Seal

THR heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications.

As one of the most commonly used seals for rotating shafts, the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing. This kind of seal is suitable for use under all pumping conditions. In situations where corrosive solids or high temperature might be encountered, Teflon or aramid fiber is used as the packing material for the gland. For high abrasion conditions, a ceramic shaft sleeve is available.

Centrifugal Seal - Expeller

The combination of impeller and expeller creates the pressure needed to seal against leakage. Together with the gland seal or lip seal which is used as the shut-down seal, this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site, or sealing water is allowed to enter inside the pumping chamber to dilute the slurry.

Mechanical Seal

THR heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement. Other types of mechanical seal are among options to suit the slurry pump for various pumping applications.

APPLICATIONS

Mining & Mineral Processing

The slow running speeds of the Tobee heavy duty rubber lined slurry pump, together with the comprehensive choice of abrasion resistant alloys and elastomers, provide unrivalled performance and service life for all abrasive mining and minerals processing applications.

Dredging Sand Project

Designed for easy and simple strip down and re-assembly, the Tobee heavy duty rubber lined slurry pump minimises downtime, making it the ideal choice where installed stand by pumps are not available.

Sand Mining Project

Wherever abrasive solids are causing premature failure of pumps, the Tobee heavy duty rubber lined slurry pump range has the right combination of performance, wear life and reliability to bring the customer the lowest cost of ownership.

FAQ

Q: Are you a factory or trading company?

A:We are a big manufacturing pump factory with 35 years experience.

Q: Where is your factory located? How can I visit there?

A:Our factory is located in Shijiazhuang City, Hebei Province, China. You can fly to Shijiazhuang airport directly. All our

clients, from home or abroad, are warmly welcome to visit us!

Q: What is the material of your pumps?

A: The materials can be selected by High chrome alloy or Rubber, Polyurethane, Cast iron, SS304, SS316, CD4MCu, Duplex SS, Bronze etc. We can also choose material as customers' requirement.

Q: Can I get some technical support?

A: Yes, of course, we will continually provide full support by 7x24.

Q:How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality controlling from the very beginning to the very end. Our

factory has 15~20QC.

Contact Us

HEBEI TOBEE PUMP CO., LIMITED

Add: Hi-tech Development Zone | Shijiazhuang City 050000 |Hebei Province | China.

Email: Sales3@tobeepump.com | Mob: +86- 18000656103 | Whatsapp: +86 18000656103 | Fax: +86 311-87221317

Web: www.tobeepump.com | Web: www.slurrypumpsupply.com | Web: www.tobee.cc | Web: www.hydroman.cn | Web: www.tobee.store

Add: Hi-tech Development Zone | Shijiazhuang City 050000 |Hebei Province | China.

Email: Sales3@tobeepump.com | Mob: +86- 18000656103 | Whatsapp: +86 18000656103 | Fax: +86 311-87221317

Web: www.tobeepump.com | Web: www.slurrypumpsupply.com | Web: www.tobee.cc | Web: www.hydroman.cn | Web: www.tobee.store

Hot Searches