1)

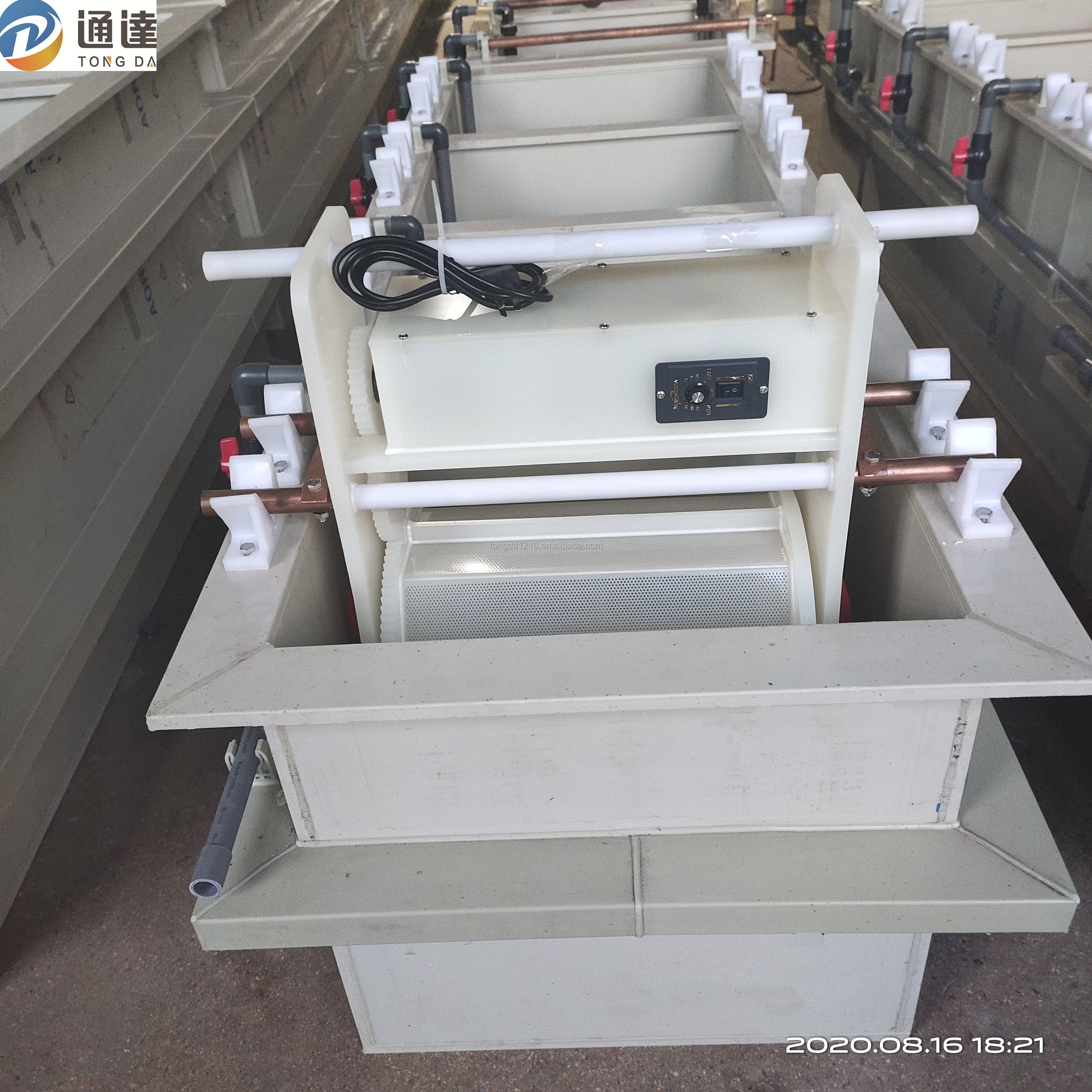

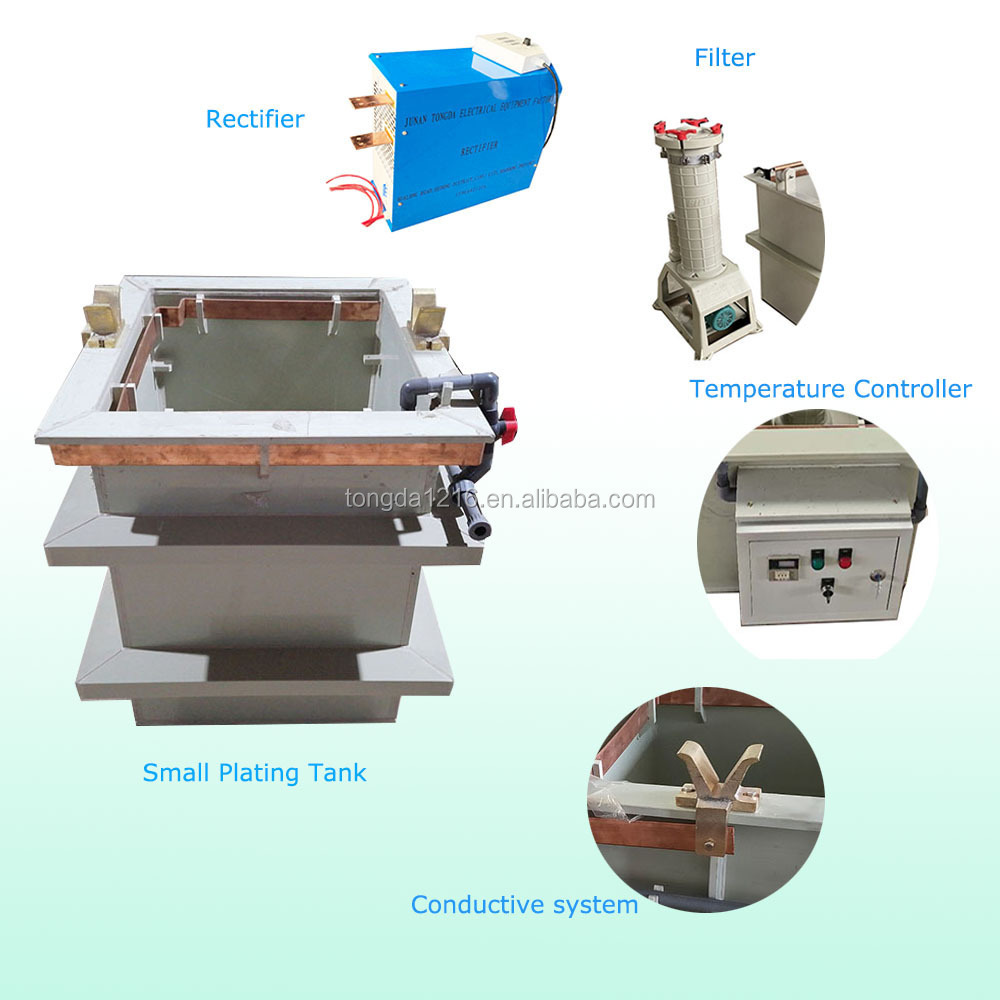

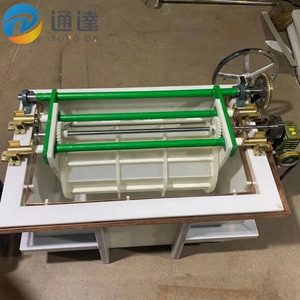

Plating Type: Manually barrel / hang plating,

small anodizing machine

3)

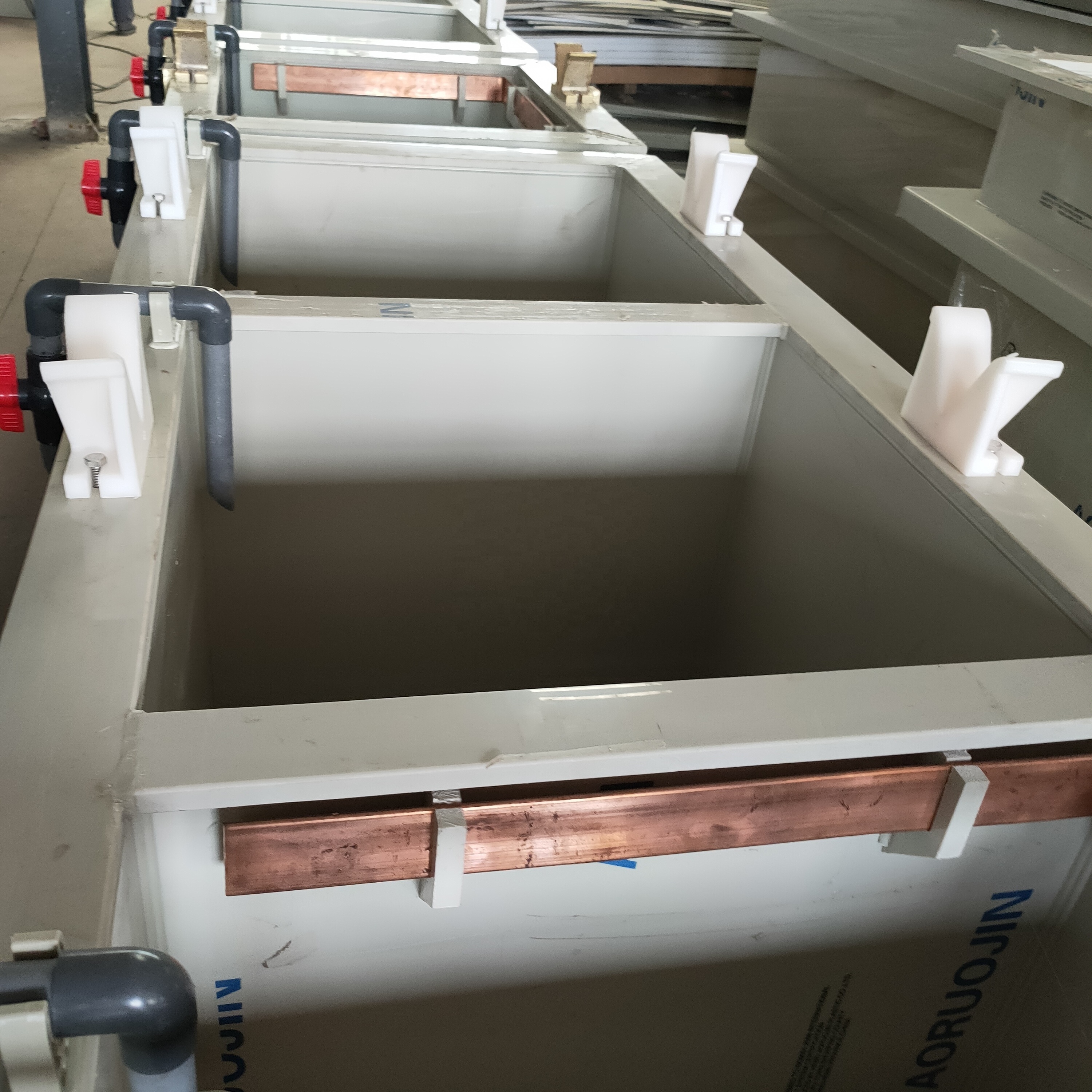

Available for: Zinc, Chrome, Nickel, Copper, Gold, Silver, Tin Plating and Anodizing etc.

4)

Tank material: 15 mm PP / PVC / SS,

Welcome customized

5)

Manufacturer of Electroplating Machine

Lifetime Technique support

Full set after-sale services