- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

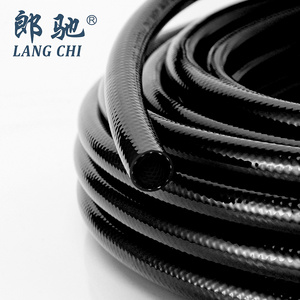

air water hose

-

Product name:

-

air brake hose

-

Size:

-

3/16"-1"

-

Color:

-

Black

-

Working pressure:

-

15 Bar

-

inner tube:

-

Synthetic Rubber Material

-

Reinforcement layer:

-

Fabric Reinforced

-

cover:

-

Weather Resistant Synthetice Rubber

-

Working temperature:

-

-40C~+120C

-

length:

-

50m 100m

-

Surface:

-

Smooth Surface Add Thread

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

OEM

-

Model Number:

-

air water hose

-

Product name:

-

air brake hose

-

Size:

-

3/16"-1"

-

Color:

-

Black

-

Working pressure:

-

15 Bar

-

inner tube:

-

Synthetic Rubber Material

-

Reinforcement layer:

-

Fabric Reinforced

-

cover:

-

Weather Resistant Synthetice Rubber

-

Working temperature:

-

-40C~+120C

-

length:

-

50m 100m

-

Surface:

-

Smooth Surface Add Thread

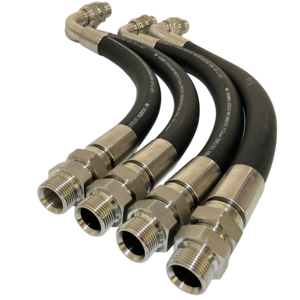

3/8" High Pressure J1402 Air Brake Hose

Product Description

Specifications

SAE J1402:2010 type 2A.

SAE J1402:2010 type 2A.

Application

used as flexible joint in automotive air brake systems. Suitable for compressed air with oil traces.

used as flexible joint in automotive air brake systems. Suitable for compressed air with oil traces.

Temperature: from -40°C (-40°F) to +100°C (+212°F).

Branding: Kingdaflex SAE J 1402 – SIZE - QUARTER / YEAR - BATCH PRODUCTION NUMBER

Tube:black, seamless synthetic rubber compound

Reinforcement: high strength synthetic fabrics.

Cover: black, seamless, synthetic rubber compound abrasion, ageing, ozone, and weather-resistant

| Inside Diameter | Outside Diameter | Burst Pressure | Nominal Weight | Bending Radius | |||||

| mm | inch | mm | inch | bar | psi | kg/m | lbs/ft | mm | inch |

| 9,5 | 3/8 | 19 | 0,75 | 60 | 900 | 0,24 | 0,16 | 89 | 3,5 |

| 12,5 | 31/63 | 22,5 | 0,89 | 60 | 900 | 0,31 | 0,21 | 102 | 4,0 |

| 14,5 | 4/7 | 24,5 | 0,97 | 60 | 900 | 0,33 | 0,22 | 115 | 4,5 |

Air and gas hoses

are designed to transfer compressed air and gases from one point to another in industrial, medical, construction and agricultural applications. These hoses are generally made up of materials like NBR (Nitrile Rubber), PVC (Polyvinyl Chloride), EPDM (Ethylene Propylene Diene Monomer), PTFE (Polytetrafluoroethylene), Silicone, etc. Generally, stainless steel or polyester fabric braiding is used as reinforcement in these hoses to ensure safety and longevity. They must also comply to various ISO, EU and US standards for air and gas safety.

| Air | Air hoses are used to convey compressed air for pneumatic systems. These air hoses must have high strength to handle high pressures in order to prevent leakage and damage. In addition, oil-based lubricants are sometimes added to the compressed air for smooth running of the equipment. Therefore, these air hoses must also be oil resistant. To handle the high pressure and oil-based lubricants, rubber is the common material choice for an air hose. |

| Gas | In industrial facilities, the gases that are transported may be toxic and/or flammable. Such applications should give special attention to selecting the right type of hose and their fittings. The gas hoses must be leak proof and resistant to breaking. |

| Materials | Rubber, PVC , PTFE |

| Rubber hose | Rubber is the most commonly used materials and is an inexpensive choice (in comparison to other materials) for air and gas hoses. These hoses are strong, flexible, durable and can handle different heat and temperature variations. Rubber compounds like EPDM and NBR also make a great choice for air and gas hoses. EPDM rubber provides great resistance with heat, temperature and ozone. Similarly, NBR is resistant to oil and chemicals. However, rubber cannot provide zero permeability and cannot be used for applications which requires high purity. A high purity gas has low amount of other gases present, making them better quality. |

| PVC hose | PVC is a widely used material for general purpose air and gas hose application. PVC hoses are inexpensive, durable and lightweight. They are lightweight, therefore, practical to use outdoors or at greater heights. |

| PTFE hose | PTFE (Polytetrafluoroethylene) hoses are suitable for high pressure industrial applications. They are durable, flexible and economical. For applications requiring high purity, PTFE can be exposed to a “post-sintering” process. During this process, the PTFE is processed again at controlled temperature and pressure. This helps in increasing the number of molecular bonds, increasing strength as well as wall thickness of the hose, resulting in reduced diffusion. |

Packaging & Shipping

Hot Searches