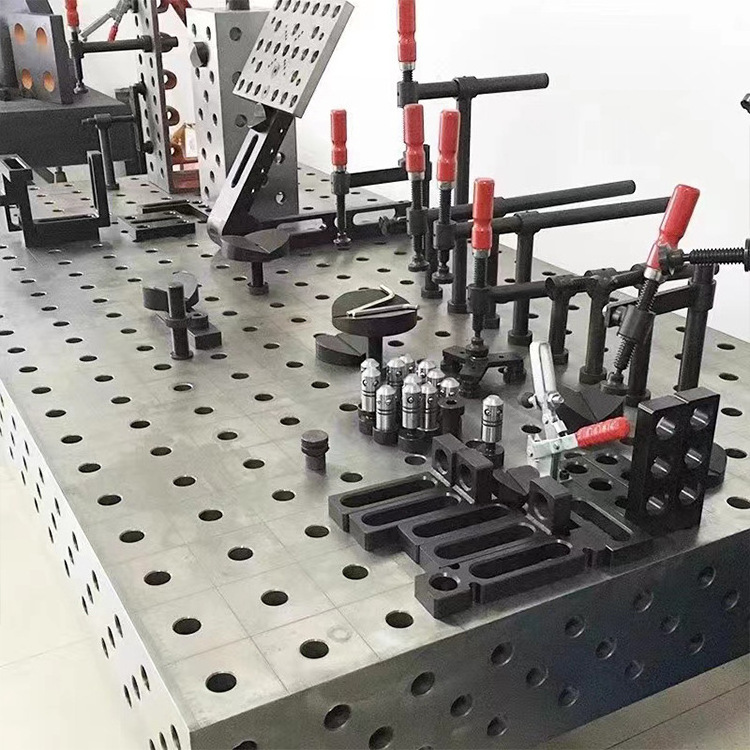

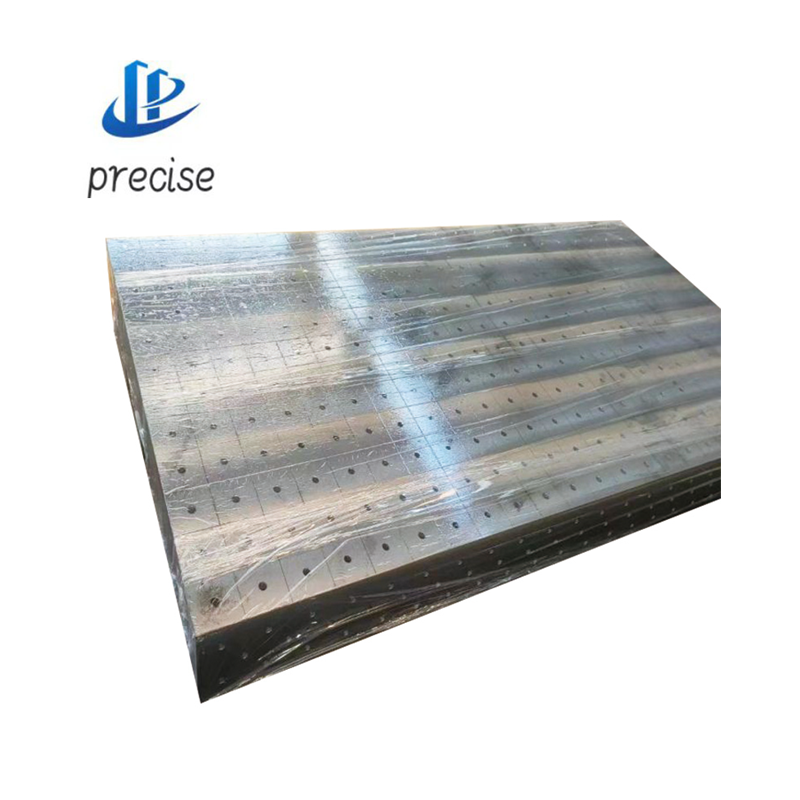

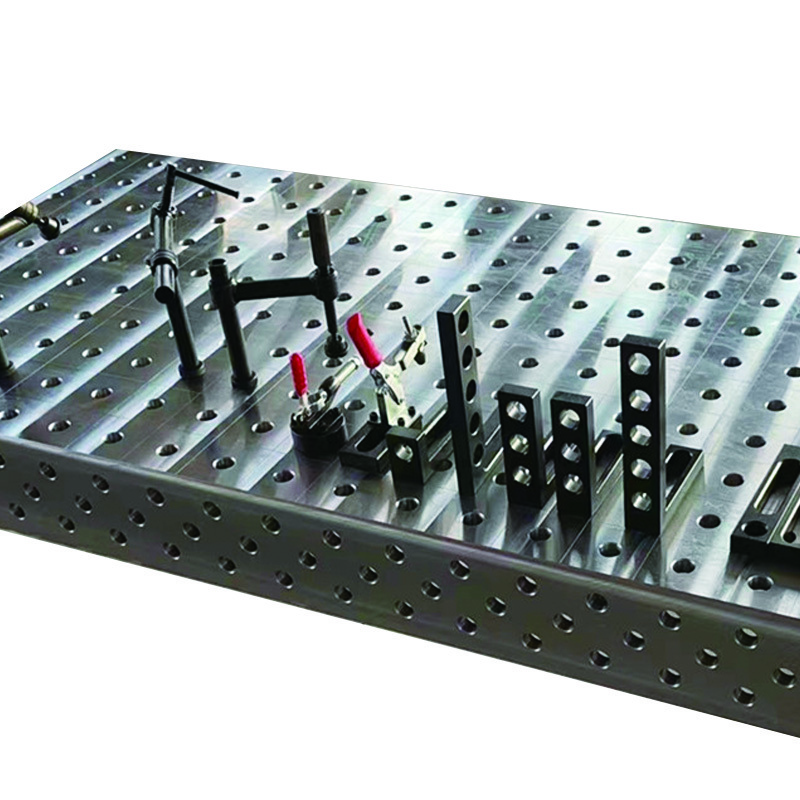

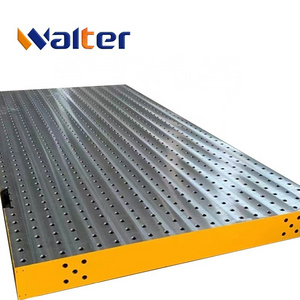

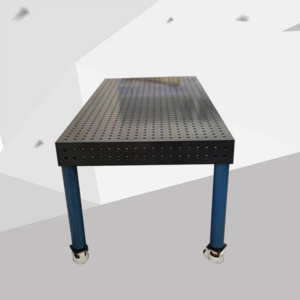

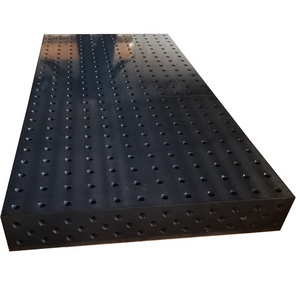

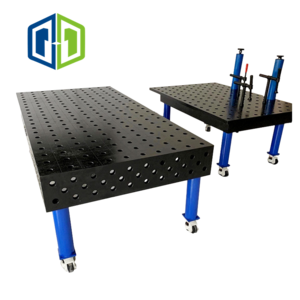

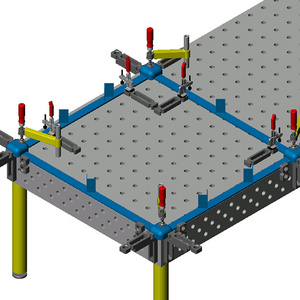

Hole spacing:L1=100±0.05mm

Flatness:0.1/1000mm

Verticality:0.1/200mm

Surface roughness:RA3.2

Standard load bearing: 2T

Frame bearing:5T

Nitriding hardness:HV450~HV630

Specifications:1000*1000~2000*4000mm

Nitriding hardness:HV450~HV630

Specifications:1000*1000~2000*4000mm