- Product Details

- {{item.text}}

Quick Details

-

Cooling Capacity:

-

50ton

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Xing Yuan

-

Voltage:

-

220V

-

Power:

-

5kw

-

Dimension(L*W*H):

-

customized

-

Weight:

-

150kg

-

Insulation types:

-

Polyurethane foam

-

Fireproof:

-

B2 Level

-

Sliding system:

-

manual

-

Rail system:

-

aluminum

-

Sealing system:

-

EPDM

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

Thailand, Bangladesh, Uzbekistan

-

Showroom Location:

-

Uzbekistan

-

After-sales Service Provided:

-

Video technical support, Online support

-

Marketing Type:

-

New Product 2020

-

Certification:

-

ce

Quick Details

-

Temperature:

-

-35℃ ~ +8℃

-

Compressor brand:

-

Bitzer

-

Panel Thickness:

-

100mm

-

Cooling Capacity:

-

50ton

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Xing Yuan

-

Voltage:

-

220V

-

Power:

-

5kw

-

Dimension(L*W*H):

-

customized

-

Weight:

-

150kg

-

Insulation types:

-

Polyurethane foam

-

Fireproof:

-

B2 Level

-

Sliding system:

-

manual

-

Rail system:

-

aluminum

-

Sealing system:

-

EPDM

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

Thailand, Bangladesh, Uzbekistan

-

Showroom Location:

-

Uzbekistan

-

After-sales Service Provided:

-

Video technical support, Online support

-

Marketing Type:

-

New Product 2020

-

Certification:

-

ce

Products Description

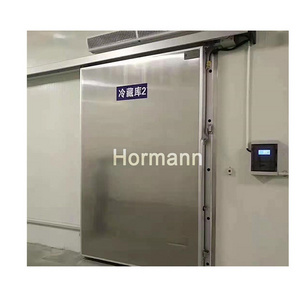

Xing Yuan Cold Room Door

Cold room door is made of polyurethane foaming materials.The metal on both sides of the doors is used of double-sided choi steel.Cold storage doors are equipped with safety device to escape.

Specifications

aluminum rail system

lock and stopper

|

Product Name

|

Cold room door

|

|

Door leaf

|

75/100/150mm Polyurethane sandwich panels with color steel(PPGI), stainless steel, aluminum

|

|

Door parts

|

Aluminum door frame and rail, stainless steel door parts

|

|

Sealing strip

|

EPDM, good chemical resistance, durable, anti-aging

|

|

Safety device

|

Safety door lock which can open the door from inside

|

|

Width

|

standard width 1000mm, maximum 3000mm

|

|

Height

|

Customized, maximum 4200mm

|

|

Optional accessories

|

Glass window, heating wires, auto control system

|

Related Products

Swing Door

Sliding door

Related Accessories

Cold room door is made of polyurethane foaming materials.The metal on both sides of the doors is used of double-sided choi steel.Cold storage doors are equipped with safety device to escape.

About Us

Changzhou New Star Refrigeration Co., Ltd. was known as Changzhou Xing Yuan Refrigeration Co., Ltd. We have more than 15 years of manufacturing cold room panels, doors, cooling equipments and accessories.

Welcome to visit our factory in NO.47 Yaoluo Road, Wujin industrial zone, Changzhou city. It's about 1 hour by train from Shanghai, 2 hours by flight from Guangzhou, and 4 hours by train from Beijing.

With the motto of "Honesty brings win-win business”, we’ve exported since 2013. Since we always focus on high quality products with reasonable price, our registered brand “Xing Yuan” is getting more and more popular at home and abroad.

New Star, New Choice.

The factory has passed the SGS audit, I S O 9 0 0 1 certification and I S O 1 4 0 0 1 certification.

How to order

|

Step

|

Contents

|

Details

|

|

1

|

Detailed requirements provided by client |

1. Is there any L*W*H size or sketch?

We can understand the dimension and how many chambers will be there. |

|

|

|

2. What is the working temperature?

We recommend -1~10℃ for fruit and vegetables, -18~ -25℃ for fish and meat. The temperature can be customized of course, and can be adjusted within ±5℃ |

|

|

|

3. If you don’t know about the Q1 & Q2, what products would you like to keep in the cold room? And how much MT please?

|

|

|

|

4. What is the power supply?

380V/50HZ/3phase or other specification |

|

|

|

5. What is the highest and lowest ambient temperature?

Is there any salty environment by the sea or not? |

|

|

|

6. Is there any other special requirement?

|

|

2

|

|

1. Discussion and modification until we reach an agreement

|

|

|

|

2. Detailed quotation for a complete set of cold room, including pictures and basic technical data

|

|

|

|

3. Sketch design (if necessary)

|

|

3

|

|

1. Sigh the contract and formal design

|

|

|

|

2. Payment: 30% by T/T in advance, 70% by T/T or L/C

|

|

4

|

Delivery and docs |

1. Prepayment 30% by T/T in advance

|

|

|

|

2. Production: normally 25~30 days per set

|

|

|

|

3. Pictures update when the products are ready

|

|

|

|

4. Balance payment by T/T or L/C

|

|

|

|

5. Delivery by sea/ train

|

|

5

|

Installation

(if necessary) |

1. Contract of the installation is made

|

|

|

|

2. Prepayment of the installation charge

|

|

|

|

3.Client prepare the construction site and foundation.

|

|

|

|

4.Client prepare the on-site electricity and water

|

|

|

|

5. Working procedure confirm and team organization;

|

|

|

|

6. Construction teams go to install.

|

|

6

|

Check and acceptance

(if necessary) |

1. Our technicians trial run the cold storage on-site;

|

|

|

|

2. Client checks and makes acceptance.

|

|

|

|

3. Balance payment of the installation charge

|

|

7

|

Operation instruction and warranty

(if necessary) |

1.Train the clients’ cold storage operators;

|

|

|

|

2. Provide technical support within the lifetime of cold storage.

|

Contact Us

Hot Searches