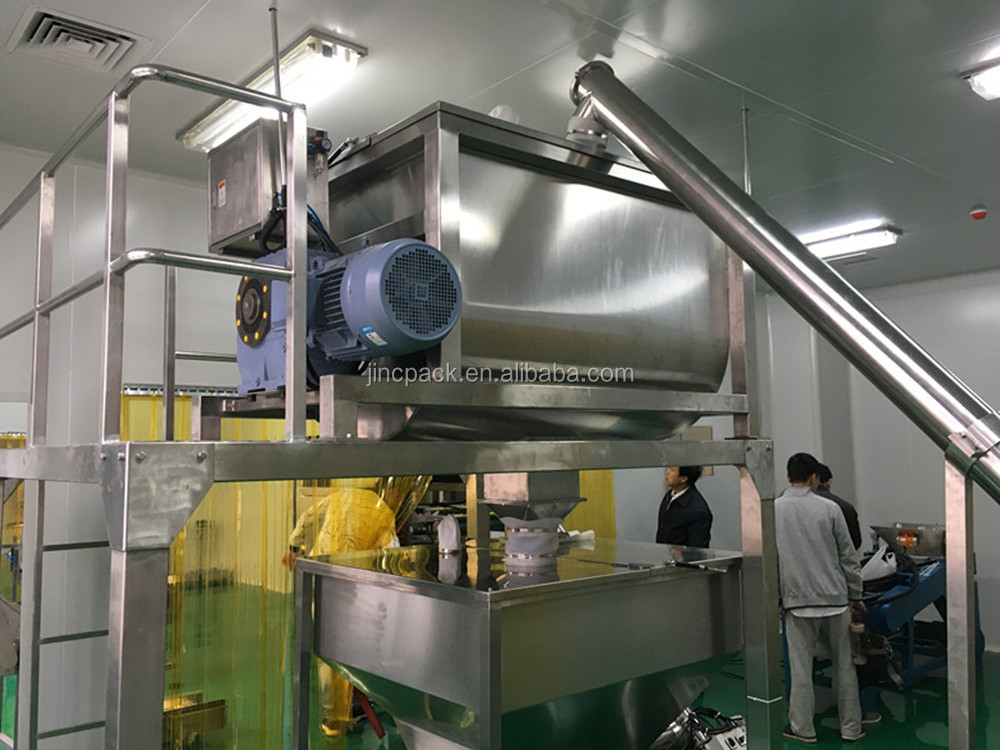

The machine consists of U-shaped containers, ribbon mixing blade and transmission component. Ribbon mixing blades are usually made into double or three layer. The outer helix collects the material from both sides to the center, and the inner helix conveys the material from the center to both sides, forming a convective mixing. The ribbon mixer has a good effect on the mixing of viscous or cohesive powder particles and the mixing of powder particles material added liquid or paste materials. The cover can be made into a fully open door to facilitate cleaning equipment and replace the product.

- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

500L

-

Weight (KG):

-

2200 KG

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

JOSO

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1773*1100*1855 mm

-

Power (kW):

-

7.5 kW

-

Marketing Type:

-

New Product 2021

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Usage:

-

Mixing material

-

Mixing type:

-

Spiral ribbon

-

After-sales Service:

-

Full life

-

Guarantee:

-

1 year

-

After Warranty Service:

-

Video technical support, Spare parts

Quick Details

-

Barrel Volume (L):

-

710L

-

Max. Loading Volume (L):

-

500 L

-

Range of Spindle Speed(r.p.m):

-

40 - 46 r.p.m

-

Max. Loading Capacity:

-

500L

-

Weight (KG):

-

2200 KG

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

JOSO

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1773*1100*1855 mm

-

Power (kW):

-

7.5 kW

-

Marketing Type:

-

New Product 2021

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Usage:

-

Mixing material

-

Mixing type:

-

Spiral ribbon

-

After-sales Service:

-

Full life

-

Guarantee:

-

1 year

-

After Warranty Service:

-

Video technical support, Spare parts

Spiral Ribbon Mixer

|

Model

|

HL100

|

HL200

|

HL300

|

HL500

|

HL1000

|

HL1500

|

HL2000

|

HL3000

|

|||||||

|

Effective Volume

|

100L

|

200L

|

300L

|

500L

|

1000L

|

1500L

|

2000L

|

3000L

|

|||||||

|

Fully Volume

|

140L

|

280L

|

420L

|

710L

|

1420L

|

1800L

|

2400L

|

4000L

|

|||||||

|

Turning Speed

|

46rpm

|

46rpm

|

46rpm

|

46rpm

|

46rpm

|

46rpm

|

46rpm

|

46rpm

|

|||||||

|

Total Weight

|

210kg

|

250KG

|

350kg

|

500kg

|

700kg

|

1000kg

|

1300kg

|

2200kg

|

|||||||

|

Total Power

|

3kw

|

4kw

|

5.5kw

|

7.5kw

|

11kw

|

15kw

|

22kw

|

22kw

|

|||||||

|

Total Length

|

1100

|

1370

|

1550

|

1773

|

2394

|

2715

|

3080

|

4270

|

|||||||

|

Total Width

|

750

|

834

|

970

|

1100

|

1320

|

1397

|

1625

|

2200

|

|||||||

|

Total Height

|

1300

|

1647

|

1655

|

1855

|

2187

|

2313

|

2453

|

2400

|

|||||||

|

Barrel Length

|

680

|

888

|

1044

|

1219

|

1500

|

1800

|

2000

|

2300

|

|||||||

|

Barrel Width

|

420

|

554

|

614

|

754

|

900

|

970

|

1068

|

1210

|

|||||||

|

Barrel Height

|

490

|

637

|

697

|

835

|

1050

|

1155

|

1274

|

1200

|

|||||||

|

Barrel Radius

|

210

|

277

|

307

|

377

|

450

|

485

|

534

|

600

|

|||||||

|

Power Supply

|

3P AC208-415V 50/60HZ

|

|

|

|

|

|

|

|

|||||||

Main Features

1) Driving advantage: the standard product is driven by gear reducer. Compared with cycloid reducer driven by belt pulley, gear reducer has overload protection function.

2) Disassemble and assemble flexibly: The main shaft of the spiral ribbon is connected with the flange of the driving shaft in the barrel body, and can be quickly dismantled when the mixing shaft needs to be repaired or replaced. Flexible disassemble and assemble design makes U-shaped cylinder and two end plates completely welded, avoiding to produce gaps in the large flange connection of the cylinder to accumulate powder machine.

3) Disconnected spiral ribbon: Compared with the connected spiral tape, it is greater that the shearing motion of the produced by the disconnected spiral ribbon. It can also form more eddies in the mixing process, accelerate the mixing speed and improve the mixing uniformity.

4) Spindle seal: When mixing ultrafine powder, the main shaft seal can increase the air-tightness setting, effectively blocking the flow of gas inside and outside.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Make plans for choice according to the needs and special requirements of users in different sectors.

After-Sales Service

* Advisory services: users encounter any problems in the use process, can call the company for technical support.

* Warranty: warranty period of the product, if quality problems, the company responsible for the warranty service.

The normal package is wooden box(Size: L*W*H). If export to foreign countries,the wooden box will be fumigated. If container is too tighter,we will use PE film for packing or pack it according to customers special request.

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 25-30 days if the goods are not in stock, it is according to quantity.

Q: How to get an accurate quotation?

A: Please provide us the detail of the workplace such as drawing and dimensions.

Q: What is your terms of payment?

A:Payment terms: 30% down payment against order by T/T, the balance of 70% to be paid on delivery. Minimum order quantity: 1 set, FOB Shanghai

Delivery time: about 20-30 working days after receipt of formal order and 30% deposit.

Warranty: 12 months following delivery. We offer online service 24 hours all day long, Skype,

Email etc. You can contact us any time, if urgently, please call us.

Q: What's policy for guarantee and broken parts?

A: As for machine products, our company provides 12 months for all mechanical parts with the exception of electrical and electronic parts and those subjects to normal wear and tear. The guarantee is intended limited to the replacement of the broken part after checking the construction fault. The inspection of the causes of the trouble or the breakdown of the parts is exclusively up to the manufacturing company. All in all, our company can offer you assured products.