- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Tesheng

-

Product name:

-

big bag unloading station

-

Keyword:

-

jumbo bag dumping station

-

Application:

-

Industrial Filed

-

Type:

-

Atuomatic

-

Usage:

-

Heavy Duty

-

Capacity:

-

1t - 300t

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Advantage:

-

High Efficiency

-

Handling capacity:

-

6-12 Bags/hour

-

Structure:

-

Conveyor System

Quick Details

-

Warranty:

-

1 Year

-

Weight (KG):

-

200

-

Place of Origin:

-

Colorado, United States

-

Brand Name:

-

Tesheng

-

Product name:

-

big bag unloading station

-

Keyword:

-

jumbo bag dumping station

-

Application:

-

Industrial Filed

-

Type:

-

Atuomatic

-

Usage:

-

Heavy Duty

-

Capacity:

-

1t - 300t

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Advantage:

-

High Efficiency

-

Handling capacity:

-

6-12 Bags/hour

-

Structure:

-

Conveyor System

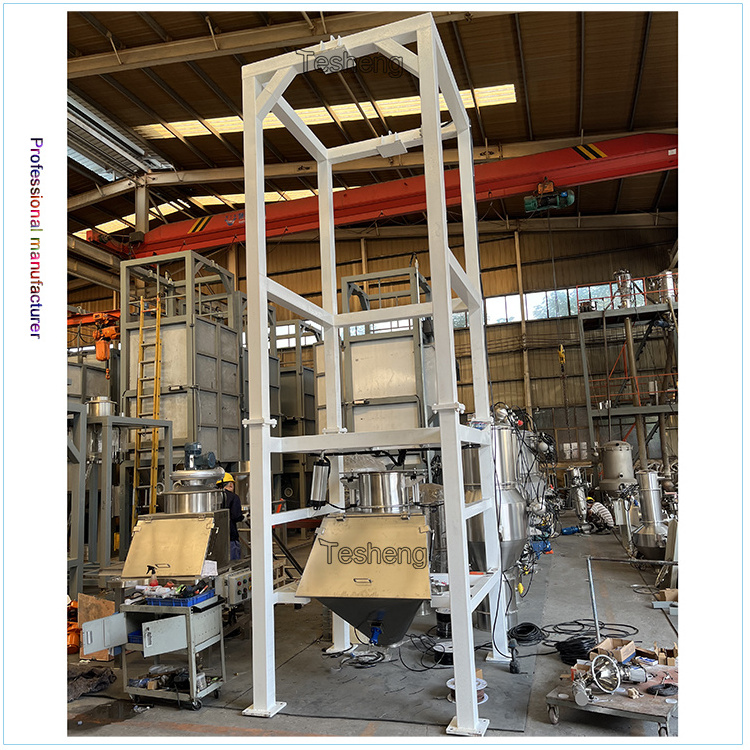

Product Description

Portable feed big bag unloading station jumbo bag

dumping station for plastic granules

Features of

big bag unloading station

1. Highly airtight

The

big bag unloading station

adopts a well-sealed box design, it can isolate the external environment.

2. High level of automation

It is usually linked with weighing, conveying to realize the automatic feeding and transmission of materials.

3. Excellent material protection performance

The closed design can provide a clean environment for the material and avoid the influence of external pollution factors on the quality of the material.

4. Easy to maintain and clean

The box and glove parts are detachable, which is convenient for regular maintenance and cleaning.

|

Bag size application

|

1000x1000x1600 mm

|

|

Power Source

|

AC 380 v ± 5%50 Hz

|

|

Air source pressure

|

≥ 0.6MPa

|

|

Air consumption

|

≤ 0.6 m ³/min

|

|

wind volume for dust-removal

|

800-2500m3/h

|

|

Environment humidity

|

-100C-400C

|

|

Cutting capacity

|

10-20 bags/h (manual)

|

The following is an

automated production line

designed for

a

Malaysian

customer

.

The bulk bag unloader unpacks and discharges the ton bag, and the material is transported to the mixer through the vacuum conveyor and the screw conveyor.

If you want to design a production line, please contact us today!

Details Images

Application

Hot Searches