- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

1500 r.p.m

-

Max. Weight of Workpiece(kg):

-

enquiry us

-

Spindle Bore(mm):

-

Inquiry us

-

Width of bed (mm):

-

0 mm

-

Spindle Motor Power(kW):

-

22

-

Max. Turned Length (mm):

-

650

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Z Axis)(mm):

-

600 mm

-

Positioning Accuracy (mm):

-

0.012

-

Repeatability (X/Y/Z) (mm):

-

0.008

-

Place of Origin:

-

Shanghai, China

-

Dimension(L*W*H):

-

Inquiry us

-

Brand Name:

-

ANTISHICNC

-

Model Number:

-

VTL-65L-S

-

Voltage:

-

380V

-

Weight (KG):

-

11000

-

Marketing Type:

-

New Product 2023

-

Machine Type:

-

CNC Vertical Lathe

-

Max. Swing over bed:

-

750mm

-

Max. turning diameter:

-

650mm

-

Spindle speeds:

-

50-1500rpm

-

Tool holder:

-

Horizontal eight-station turret

-

Spindle head type:

-

A2-8

-

Spindle bearing:

-

NSK

-

Payment:

-

T/T

-

Packing:

-

Factory standard package

-

Net weight:

-

11000kg

Quick Details

-

Type:

-

VERTICAL

-

Max. Length of Workpiece (mm):

-

800

-

Year:

-

2023

-

Max. Spindle Speed (r.p.m):

-

1500 r.p.m

-

Max. Weight of Workpiece(kg):

-

enquiry us

-

Spindle Bore(mm):

-

Inquiry us

-

Width of bed (mm):

-

0 mm

-

Spindle Motor Power(kW):

-

22

-

Max. Turned Length (mm):

-

650

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Z Axis)(mm):

-

600 mm

-

Positioning Accuracy (mm):

-

0.012

-

Repeatability (X/Y/Z) (mm):

-

0.008

-

Place of Origin:

-

Shanghai, China

-

Dimension(L*W*H):

-

Inquiry us

-

Brand Name:

-

ANTISHICNC

-

Model Number:

-

VTL-65L-S

-

Voltage:

-

380V

-

Weight (KG):

-

11000

-

Marketing Type:

-

New Product 2023

-

Machine Type:

-

CNC Vertical Lathe

-

Max. Swing over bed:

-

750mm

-

Max. turning diameter:

-

650mm

-

Spindle speeds:

-

50-1500rpm

-

Tool holder:

-

Horizontal eight-station turret

-

Spindle head type:

-

A2-8

-

Spindle bearing:

-

NSK

-

Payment:

-

T/T

-

Packing:

-

Factory standard package

-

Net weight:

-

11000kg

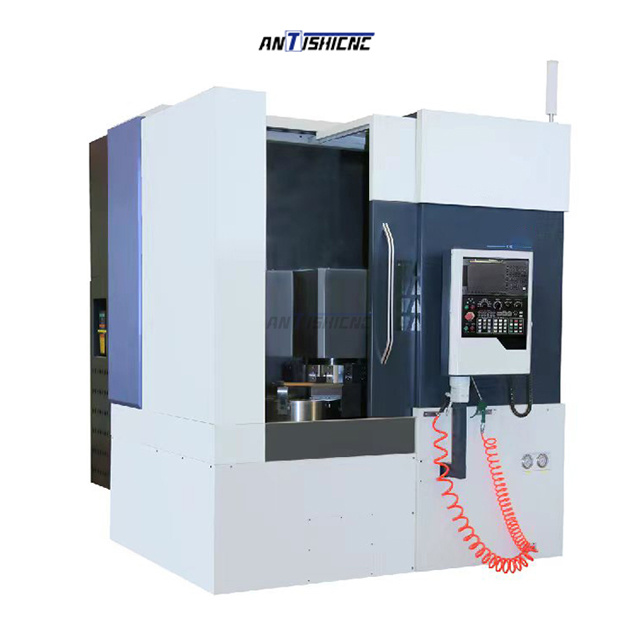

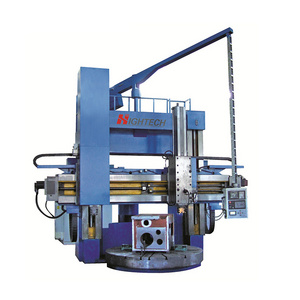

ANTISHICNC VTL-65L-S CNC Vertical Lathe Machine Double Column Vertical Lathe Turning and Milling Compound China Factory Price

|

Device Name

|

CNC Vertical Turning and Milling

|

|

|

Model

|

VTL-65L-S (Turning and milling)

|

|

|

System

|

GSK 988TD

|

|

|

Travel

|

|

|

|

X axis

|

300mm/300mm

|

|

|

Z axis

|

600mm/600mm

|

|

|

Capacity

|

|

|

|

Max. Swing over bed

|

Φ750mm

|

|

|

Max. turning diameter

|

Φ650mm

|

|

|

Spindle

|

|

|

|

Spindle speeds

|

50~1500rpm(timing belt)

|

|

|

Spindle motor power

|

18.5Kw(direct connection)

|

|

|

Spindle head type

|

A2-8

|

|

|

Spindle bearing

|

NSK

|

|

|

Spindle hardness

|

HRC58-62

|

|

|

Reduction ratio

|

/

|

|

|

Chuck & Automatic Tool Changer

|

|

|

|

Tool holder

|

Horizontal eight-station turret

|

|

|

Chuck

|

Φ500

|

|

|

Slide Way

|

|

|

|

X-axis rolling linear guide

|

45mm

|

|

|

Z-axis rolling linear guide

|

45mm

|

|

|

Ball Screw

|

|

|

|

Ball screw accuracy

|

Class C3

|

|

|

Ball screw diameter

|

X1、Z1:φ50/X2、Z2:φ40

|

|

|

Screw bearing

|

NSK

|

|

|

Control System

|

|

|

|

X axis motor

|

18NM

|

|

|

Z axis motor

|

18NM

|

|

|

Feed Rate

|

|

|

|

X Z axis rapid feed rate

|

16m/min

|

|

|

Accuracy

|

|

|

|

Repeat positioning

|

0.008mm

|

|

|

Positioning

|

0.012mm

|

|

|

Axial run out of spindle end

|

0.005mm

|

|

|

Spindle centering shaft radial run out

|

0.005mm

|

|

|

Cutting feed rate

|

|

|

|

Least input increment

|

0.001mm

|

|

|

Power Require

|

|

|

|

Power source

|

3¢-AC 380V 50Hz±5%

|

|

|

Others

|

|

|

|

The hydraulic pressure stands

|

|

|

|

Cross weight

|

11T

|

|

|

Dimensions (L×W×H)

|

2700*2350*3000

|

|

ANTISHICNC VTL-65L-S CNC Vertical Lathe Machine Double Column Vertical Lathe Turning and Milling Compound China Factory Price

Product Details

1.The key components such as the base, column, column slide plate and slider are all made of high-grade gray cast iron (HT300). The layout of the ribs is reasonable, and each component is tempered to ensure that the machine tool has high strength and long-term accuracy and stability .

2.The machine tool adopts the structure of double columns. There are two columns, two column slide plates and sliders on the base. The motor is placed in the middle of the columns, which effectively saves space and occupies a small area. The double column can process the rough turning and finishing of the work piece at the same time. On the premise of ensuring the accuracy, it can effectively improve the customer's processing production efficiency and reduce production costs.

3.The spindle part of the machine tool is a spindle unit, which effectively ensures the machining accuracy and roughness. The inner bearing of the spindle unit is lubricated with special grease, which is convenient for installation and maintenance. Compared with the previous oil lubrication, the use cost of the spindle unit is reduced, the speed is higher, and it is more stable.

4. The machine tool adopts roller type linear slides. Has ultra-high rigidity and ultra-heavy load capacity. The positioning accuracy and bearing capacity of the vertical and horizontal feed motion of the machine tool are greatly improved.

5. The machine tool spindle pulley and the spindle CNC servo motor pulley are directly connected through the synchronous belt, and equipped with a servo motor, step less speed change, and a wide speed change range. The servo motor can meet the different requirements of the roughing and finishing of the parts on the spindle speed. The motor is selected with a larger specification to eliminate the influence of the large cutting amount of the work piece and the intermittent cutting on the motor, the work piece and the machine tool.

6.Both vertical and horizontal feeds are automatically controlled by servo motors. There are protective devices in both directions, which are separated from the processing area to reduce the influence of iron filings and iron powder on the screw motor.

7.Both ends of the ball screw in the vertical and horizontal directions of the machine tool are supported by special bearings for the screw, which greatly improves and guarantees the machining accuracy of the machine tool for parts.

8.The machine tool adopts an electric lubricating oil pump to automatically lubricate each part in an intermittent manner to ensure the lubrication of each guide rail pair and ball screw pair, which can prolong the service life of each motion pair.

9. The left side of the double-column CNC machine tool is equipped with a BT40 spindle with a 16-station tool magazine, and the right side is equipped with a horizontal eight-station tool turret. After the turning processing is completed, the work piece can be drilled, tapped and other processing requirements.

10. The upper end of the spindle can be equipped with a disc table or a hydraulic chuck according to user requirements. The lower end of the main shaft is equipped with a rotary oil cylinder. The rotary oil cylinder can be used to control the tooling to press the work piece, or to control the hydraulic chuck, which can reduce the labor intensity of workers and improve efficiency.

ANTISHICNC VTL-65L-S CNC Vertical Lathe Machine Double Column Vertical Lathe Turning and Milling Compound China Factory Price

Standard accessories

|

No

|

Name

|

Specification

|

Quantity

|

|

1

|

Machine

|

VTL-65L-S

|

1 set

|

|

2

|

CNC system

|

GSK988TD

|

1 set

|

|

3

|

Spindle unit

|

Taiwan

|

1 set

|

|

4

|

Spindle bearing

|

NSK

|

|

|

5

|

Servo spindle drive

|

GSK

|

2 sets

|

|

6

|

Servo spindle motor

|

GSK

|

2 sets

|

|

7

|

X/Z servo drive

|

GSK

|

1 set/each

|

|

8

|

X/Z servo motor

|

GSK

|

2 sets/each

|

|

9

|

Drilling spindle BT40

|

Taiwan

|

1 set

|

|

10

|

Guide rail, lead screw

|

HIWIN

|

|

|

11

|

Tool magazine

|

AIMACH/OKADA

|

1 set

|

|

12

|

Servo turret

|

IEEPO/MYKUN

|

1 set

|

|

13

|

Hydraulic chuck

|

China

|

1 set

|

|

14

|

Rotary cylinder

|

Φ150

|

1 set

|

|

15

|

Hydraulic station

|

China

|

1 set

|

|

16

|

Working lamp

|

ONLION

|

|

|

17

|

Electrical device

|

Schneider

|

|

|

18

|

Chip removal

|

Chip conveyor

|

2 sets

|

|

19

|

Fully enclosed protective cover

|

|

|

Hot Searches