- Product Details

- {{item.text}}

Quick Details

-

Working temperatur:

-

-30℃-50℃

-

Heating parts size:

-

10mm-6000mm

-

Application:

-

Pipeline coating preheating

-

Input voltage:

-

3*380VAC (Default), 3*220VAC (Optional), 3*440VAC (Optional)

-

Frequency:

-

2KHZ ~ 30KHZ

-

Power:

-

5KW-80KW

-

Cooling type:

-

Air cooling

-

Heating temperature:

-

Max:1000℃

Quick Details

-

Place of Origin:

-

Shandong, China (Mainland)

-

Brand Name:

-

ENWEI

-

Weight (KG):

-

240

-

Working temperatur:

-

-30℃-50℃

-

Heating parts size:

-

10mm-6000mm

-

Application:

-

Pipeline coating preheating

-

Input voltage:

-

3*380VAC (Default), 3*220VAC (Optional), 3*440VAC (Optional)

-

Frequency:

-

2KHZ ~ 30KHZ

-

Power:

-

5KW-80KW

-

Cooling type:

-

Air cooling

-

Heating temperature:

-

Max:1000℃

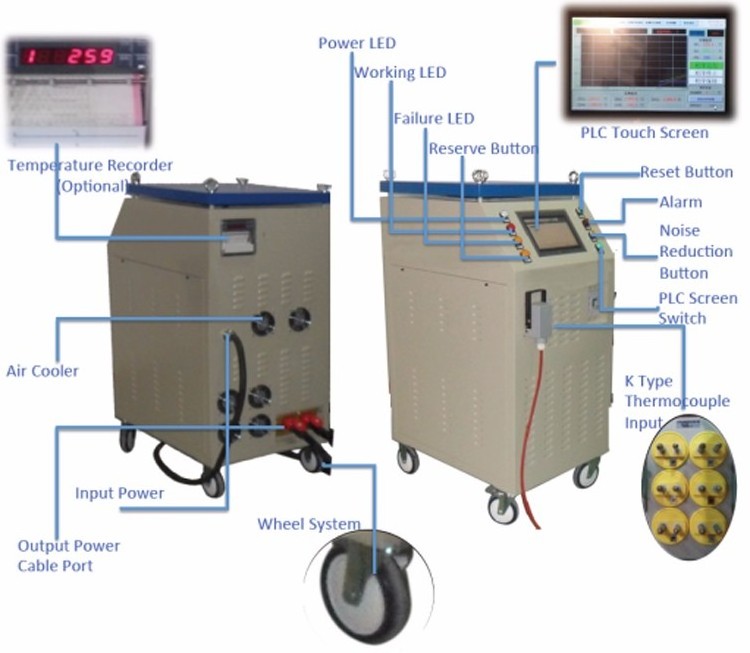

Induction heating equipment for steel preheating

Induction heating is a method to heat workpieces by generating eddy current inside through electromagnetic induction.Thanks to its advantages, this equipment is widely used for PWHT, preheat before welding, anti-corrosion coating mainly in oil and gas pipeline construction and offshore platform construction. Professional for heat treatment of copper and steel pipes, joints, flange,circular and longitudinal seams, pipeline support crack, rotor thermal, and so on.

The option parts of induction heating system:

Induction heating power

Induction coil (Clamp induction coil) or (Soft induction coil)

Extent cable for coil and the heating power

Temperature controller

PLC touch screen

Temperature recorder with printer

K type thermocouple

Extent cable and connector for thermocouple

Insulation Blanket

Induction heating power:

Other parts:

|

Model

|

EWD-S5

|

EWD-S10

|

EWD-S20

|

EWD-S30

|

EWD-S40

|

EWD-S50

|

EWD-S60

|

EWD-S80

|

|||||||

|

Input voltage

|

3*220VAC

|

3*380VAC (Default), 3*220VAC (Optional), 3*440VAC (Optional)

|

|

|

|

|

|

|

|||||||

|

Frequency

|

2KHZ ~ 30KHZ

|

|

|

|

|

|

|

|

|||||||

|

Power

|

5KW

|

10KW

|

20KW

|

30KW

|

40KW

|

50

|

60KW

|

80KW

|

|||||||

|

Current

|

22A

|

15A

|

30A

|

45A

|

60A

|

75

|

90A

|

120A

|

|||||||

|

Cooling type

|

Air cooling

|

|

|

|

|

|

|

|

|||||||

|

Heating range

|

¢100-1500mm

|

|

|

|

|

|

|

|

|||||||

|

Heater size

|

590*840*1160mm

|

|

|

|

|

|

|

|

|||||||

|

Packing size

|

620*870*1460mm

|

|

|

|

|

|

|

|

|||||||

|

DSP control:

|

Max:900℃; Heating Speed: 5-400℃/min

|

|

|

|

|

|

|

|

|||||||

|

Power weight

|

10kg

|

12 kg

|

15 kg

|

18 kg

|

20 kg

|

29kg

|

33kg

|

45kg

|

|||||||

|

Weight

|

Net weight: 106kg;Gross weight with parts: 120-240kg

|

|

|

|

|

|

|

|

|||||||

|

Main parts

|

K Thermocouple;Induction coil;Connection cable;Thermocouple Connection cable;Insulation Blanket

|

|

|

|

|

|

|

|

|||||||

The using fields involved are petrochemical, oil and gas pipelines, aerospace, shipbuilding, steel, tanks, boilers, vessels, pressure vessels, cylinders, metal structure, spatial structure, railway bridges, electricity water, mine construction, vehicle manufacturing, nuclear power, mining, plastics processing, energy saving process, mold, screw barrel industries, etc.

Pipeline coating preheat

welding preheating

:

Uniform heat

Quick direct heat

Energy Saving 30-80%

Air cooling: working well at -10℃-40℃

Induction heating power: To heat the work job with insulation blanket around it. High heating speed and heating efficiency with little energy lost.

PLC touching screen: Intuitive to see and easy to operate.

Soft induction coil: Easy to wind on different work piece.

The Removable opening Induction coil: easy to operate and move.

Temperature recorder: Record the whole heating curve.

Temperature Controller: Heating according to the heating requirement details with the ±3℃ tolerance.

Induction heating power,flexible wire induction coil and thermocouple are the standard choice, generally choose the standard fumigation-free wood packing boxes for packaging.Other accessories, according to the specific items to choose the appropriate packaging.

Q: Why choose our Company?

A: We are manufacture which had in this filed for nearly 20 years.No matter quality,price,service,delivery time,we all have large advantage.

Q:How to choose suiteble machine?

A:You can tell us your application,need forging,hardening,welding,melting or other,pass me workpiece material & size,Temperature requirement and heating time requirement.Then we will recommend fit machine for you reference.

Q:How about the machine delivery time?

A: Small machine delivery time is 3~7 workdays.Big machine delivery time 15~25 workdays.

Q:How about the machine warranty?

A:Our goods support one year warranty not by personal purpose,support technical service all life.

During the warranty,if machine have problem need change spare parts,we can replace for you charge free.

Contact:

Mobile/Wechat:+86-18660767011

Whatsapp:+86-15066371715