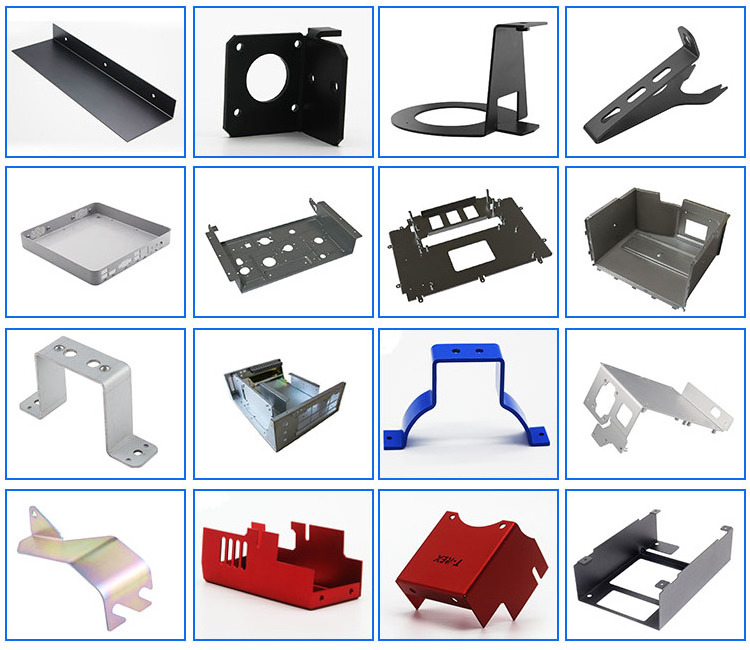

production parts.

ISO 9001:2015

|

Available Materials

|

aluminum,steel,stainless steel,brass,copper,iron, etc

|

|

|

|

||||

|

Surface treatment

|

All kinds of surface treatments are available, polishing, zinc plating, nickel plating, chrome plating, powder coating, and phosphate coating.

|

|

|

|

||||

|

Processings

|

Laser Cutting, Precision Stamping, CNC Bending, CNC Milling, CNC Turning, Threading, Riveting, Drilling, CNC Punching, Die Casting, Laser Welding, etc.

|

|

|

|

||||

|

Tolerance

|

DIN ISO 2768, 100% QC quality inspection before delivery, can provide quality inspection form.

|

|

|

|

||||

|

Drawing Accepted

|

IGS、STP、X_T、DXF、DWG、Pro/E、PDF

|

|

|

|

||||

|

Sample Cost

|

Free of Sample Cost. Normally is USD 35~110 per Style Of Special Design We Need Sample Charge, Can Refund when You Have Official Bulk Order.

|

|

|

|

||||

|

Delivery Time

|

1-25 days after order with prepayment based on products structure and quantity

|

|

|

|

||||

|

|

|

|

|

|||||

Q: Is your organization committed to the concept of total quality management? A: Yes, no matter in laser cutting, bending, or CNC machining, the workers will conduct the first sample inspection and random inspection during the processing to ensure the quality of the products. Q: How many checks are performed on a project? A: Usually, products will go through the following four inspections: incoming inspection, production first inspection, sampling inspection, and pre-shipment inspection. Among them, sampling inspection will be conducted multiple times Q: Will you be able to work with our engineering team to review drawings and provide quick, estimated pricing for desired changes? A: Yes, our engineers respond very quickly. If there is anything to be modified in the product, we can offer you a new price as soon as you tell us. Q: What kinds of information do you need for a quote? A : Kindly please provide the product drawing in PDF,and will be better you can provide in .dwg / .stp / . iges / .stl , Send drawing Q: What tolerances can Bergek achieve?? A: There is not a given set of tolerances that fits all processes and materials. In every case, the final tolerances on your part will depend on a number of factors, including but not limited to: ● Part size ● Design geometry ● The number, type, and size of features ● Material(s) ● Surface finish ●Manufacturing process Once your order is confirmed, we will review your design and provide a design for manufacturing review, pointing out any areas where we may not be able to achieve your desired tolerances. It’s helpful if you can specify which areas in your design have critical tolerances that must be met and which can be slightly modified if needed to reduce the time and costs involved. Here are some general tolerance guidelines: General tolerances for CNC machining in metal and plastic Refer to DIN ISO 2768 All manufacturing and technical specifications need to be clearly specified in the 2D drawings in order to be followed. Q: Will your company sign an NDA? A: Yes The final interpretation is owned by BERGEK