Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DEYI

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

23m*2.3m*2.2m

-

Power (kW):

-

130

-

Weight:

-

9 KG

-

Name:

-

PE polyethylene cushion foam mattress Sheet making machine

-

Raw material:

-

PE Granules

-

Usage:

-

Plastic Forming Machine

-

Type:

-

Film Extrusion

-

Capacity:

-

70-120KG/H

-

Heating way:

-

Electrical Heating

-

Color:

-

Customsized

-

Processing Type:

-

Foaming Machine

-

Power(W):

-

130KW

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

55:1

-

Screw Speed (rpm):

-

45 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DEYI

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

23m*2.3m*2.2m

-

Power (kW):

-

130

-

Weight:

-

9 KG

-

Name:

-

PE polyethylene cushion foam mattress Sheet making machine

-

Raw material:

-

PE Granules

-

Usage:

-

Plastic Forming Machine

-

Type:

-

Film Extrusion

-

Capacity:

-

70-120KG/H

-

Heating way:

-

Electrical Heating

-

Color:

-

Customsized

-

Processing Type:

-

Foaming Machine

-

Power(W):

-

130KW

Products Description

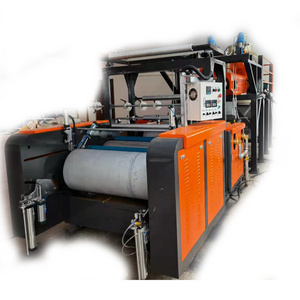

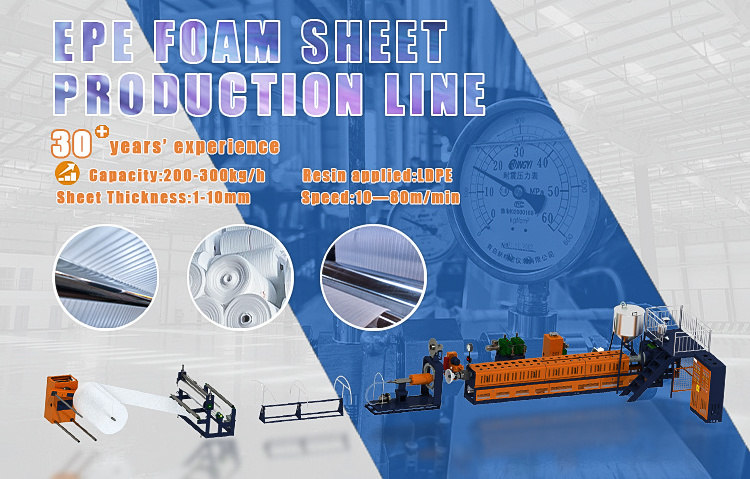

EPE foam sheet making machine pe foam sheet extrusion line

EPE foam machine can make different foam sheet widths and thicknesses according to customer requirements. Meanwhile, it can also make foam pipe, foam net, foam rod, foam profile, and so on through changing mould and machine parts. The foam sheet has the features of dampproof, shockproof, soundproof, heat preservation, and good plasticity. After laminating, the foam sheet will get high dampproof performance. These products are mainly used for placing underfloor.

e

epe pe polystyrene foam net sheet film extruder extrusion production line making machine

Machine Parameter

|

Model

|

Unit

|

EPE105

|

EPE120

|

EPE150

|

EPE170

|

EPE180

|

EPE200

|

EPE220

|

|||||||

|

Screw diameter

L/D |

|

105/55:1

|

120/55:1

|

150/55:1

|

170/55:1

|

180/55:1

|

200/55:1

|

220/55:1

|

|||||||

|

Screw speed

|

r/min

|

5-45

|

5-45

|

5-45

|

5-45

|

5-45

|

5-45

|

5-45

|

|||||||

|

Foam rate

|

|

20-40

|

20-40

|

20-40

|

20-40

|

20-48

|

20-48

|

20-48

|

|||||||

|

Width of product

|

mm

|

1000-1500

|

1000-2000

|

1000-2000

|

1000-2000

|

1000-2000

|

1000-2000

|

1000-2000

|

|||||||

|

Thickness of product

|

mm

|

0.5-6.5

|

0.8-8

|

1-12

|

2-16

|

2-18

|

3-20

|

4-25

|

|||||||

|

Cooling method

|

water cooling

|

|

|

|

|

|

|

|

|||||||

|

total power

|

kw

|

130

|

170

|

240

|

285

|

320

|

350

|

420

|

|||||||

|

Dimensions

(L×W×H)(approx) |

m

|

23×2.3×2.2

|

25×2.3×2.2

|

30×2.3×2.2

|

32×2.3×2.2

|

34x2.8x3.5

|

38x2.8x3.8

|

45X2.8X3.8

|

|||||||

|

Total weight

(approx) |

t

|

9

|

12

|

15

|

17

|

15.5

|

18

|

22

|

|||||||

Detailed show

Talcum powder injection unit

adopts Italy technology. Double screw substitute single screw, Solve the poor mobility features oftalcum powder.

The motor is controlled by inverter to make talcum powder injection accurate and stable.

The motor is controlled by inverter to make talcum powder injection accurate and stable.

Gear Box And Automatic Feeder

1. the driving seystme adopts well-known brands: GUOMAO gear box and Simense motor

2. the whole body of automatic feeding hopper is made from stainless steel #304.

2. the whole body of automatic feeding hopper is made from stainless steel #304.

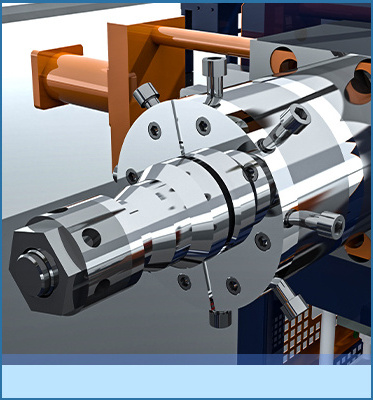

Die Head

Die lip Material:carbonalloysteel

Material:carbonalloysteel the thickness controlof sheet: regulated by the distance between mold heads

Connecting Neck

Neck Model: Cooling water jack,own-made by DEYI company

Function: prevent material sticking at the inlet of hopper when material injecting.

Material: FCD25 mollealle iron

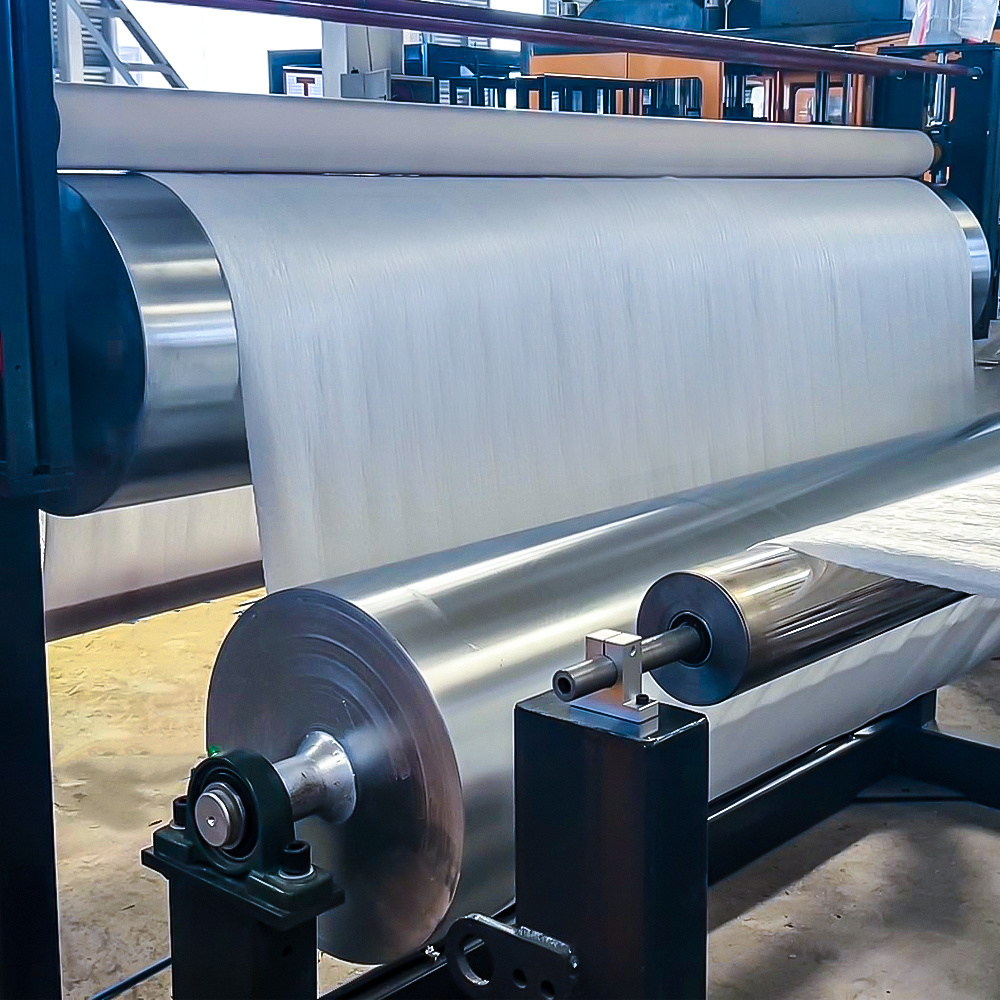

Winding Unit

Model: Double axis cantilever displacement Ttype(air shaft type)

Maximum of rolling weight: Maximum 30kg×1m(diameter)

Haul-off unit

Install static electricity eliminator under haul-off unit (ion fan).

The black oneMaterial of expanding roller: stainless steel

Material: STPG tube hard chrome plating

Material: STPG tube hard chrome plating

Main Extruder

Special Neck :Cooling water jack,prevent material sticking at the inlet of hopper when material injecting.

Screw And Barrel: 38CrMoAlA nitrogen treatment.

Method of heating:cast aluminum heater

Method of cooling: inner and outer water coooling pipe.

Screw And Barrel: 38CrMoAlA nitrogen treatment.

Method of heating:cast aluminum heater

Method of cooling: inner and outer water coooling pipe.

Details Images

FAQ

Hot Searches