- Product Details

- {{item.text}}

Quick Details

-

Advantage:

-

factory price

-

Package:

-

Carton Box/Plastic case/wooden box/iron Box, etc.

-

Grade:

-

YG8, or customized

-

Color:

-

as your requests

-

Application:

-

sand making machine

-

Trial order:

-

Accepted

-

Properties:

-

high wear resistance,good impact resistance

Quick Details

-

Weight (KG):

-

5

-

Place of Origin:

-

Sichuan, China

-

Product name:

-

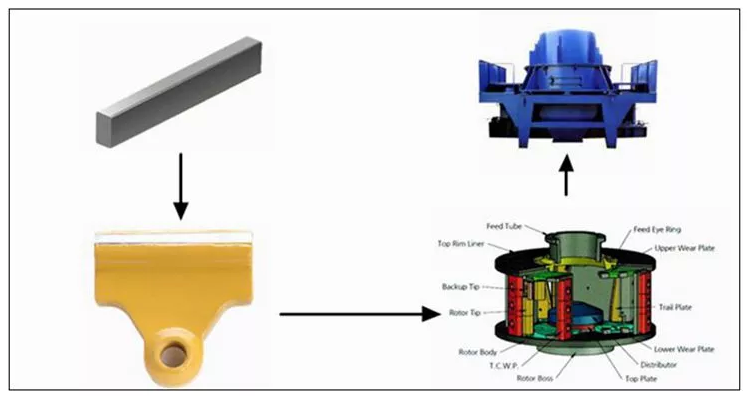

vsi crusher rotor tip

-

Advantage:

-

factory price

-

Package:

-

Carton Box/Plastic case/wooden box/iron Box, etc.

-

Grade:

-

YG8, or customized

-

Color:

-

as your requests

-

Application:

-

sand making machine

-

Trial order:

-

Accepted

-

Properties:

-

high wear resistance,good impact resistance

Product Description

i. Advantage of sand making machine wear resistance part

1. perfect performance

2. stable quality

3. 100% virgin raw material

4. various size accroding to your demand

5. fast delivery

ii. Application

Crusher hammer tungsten carbide bar are equipped with tungsten carbide that protects the rotor of the VSI crusher against wear, mainly used for break stone or into sand, they are widely used in the field of cement, mining etc.

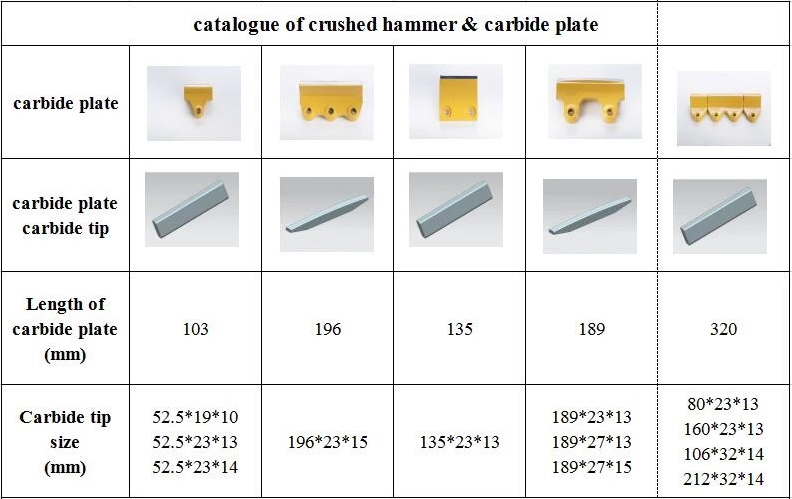

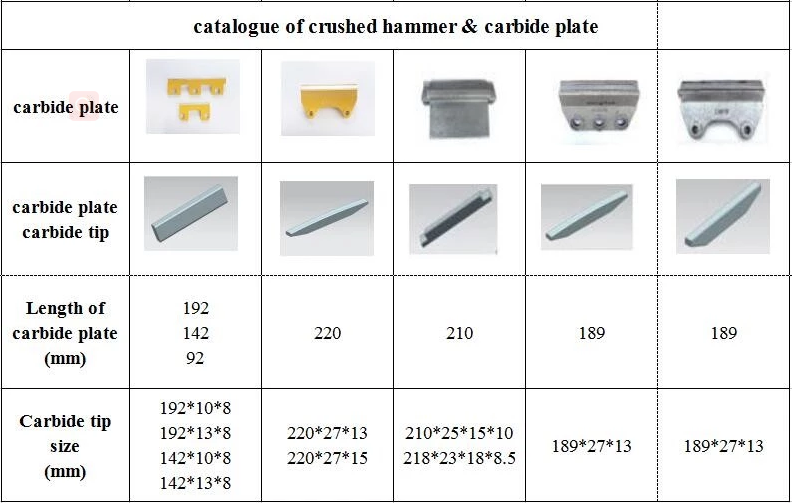

iii. Reference Size of sand making machine wear resistance part -- rotor tip

|

Material

|

tungsten carbide / steel

|

|

Coating

|

No / or as you request

|

|

Chemical Composition

|

WC≥ 85.0% or as you request

|

|

Hardness (HV)

|

1475~1675

|

|

Hardness (HRC)

|

45/50/55/58/60/65

|

|

Compressive Strength (N/mm2)

|

5600

|

|

Transverse-rupture strength (N/mm2)

|

3600

|

|

Frature Toughness

|

10.0

|

iv. Reference Grade of sand making machine wear resistance part -- rotor tip raw material

|

Grade

|

Physical Properties

|

93

|

6

|

1

|

||||

|

D30UF

|

Density

g/cm 3 |

Coercivity

kA/m |

Hardness

HRA |

TRS

≥N/mm 2 |

||||

|

YG6

|

14.82-15.05

|

12.5-17.5

13.0-17.0

|

90.5-92.0

|

1720

|

||||

|

YG6K

|

14.85-15.0

|

8.5-12

|

89.4-90.2

|

2200

|

||||

|

YG8

|

14.62-14.82

|

10.0-15.0

11.0-15.5

|

89.5-91.0

|

1800

|

||||

|

YG8C

|

14.6-14.8

|

6.3-9.3

|

87.5-89.0

|

2000

|

||||

|

ZE20

|

14.85-15.05

|

-

|

90.5-91.5

|

2880

|

||||

|

ZK20

|

14.88-14.98

|

13.0-13.8

|

>91

|

2800

|

||||

|

More

|

K10

|

94

|

6

|

0

|

||||

Hot Products

Company Profie

Locates at the new industrial park in

Zigong

, Sichuan, the famous production base for cemented carbide in China. The

factory

is mainly working on the production and development of all kinds of

cemented carbide products

, like

rods pipe

, carbide

boring bar

,

flat bars

and

tools,

etc

. In China, our goal is to become the central base of manufacture of extruded rods, carbide boring bar, standard cutters, non standard cutters and hard-machining cutters, establishing a good and healthy company image among coterie.

Main Production Equipment:

At present,the company can. In general, our products can be used in manufacture of mould, electronics, car engine and accessories, military device, petroleum machinery, machinofacture, etc. We have stable customers, such as the

United States, Russia, Indonesia, South Korea, Japan, Australia

and so on.

Testing Machine:

Our company was established in July, 2011, the company’s product quality and public praise have reached the domestic middle upper level, merely behind several the most competing cemented carbide companies. we continuously improve techniques and introduce advanced equipment, enhancing the professionalism and production scale to a large extent.

Production Flow Chart:

Packing & Delivery

Packing of Customization

1>Put the goods encased with plastic bag or plastic box in wooden box/carton/iron box, etc.

2>Other packing will be accept customized.

1>Put the goods encased with plastic bag or plastic box in wooden box/carton/iron box, etc.

2>Other packing will be accept customized.

FAQ

Q1: How long is your delivery period?

A1: It depends on specific conditions. However, it could be 10 to 15 days on average.

Q2: Do you offer samples?

A2: Yes, we do offer samples. However, buyers need to pay for the freight charge. In addition, whether samples are free or not depends on the quantity you buy.

Q3: How do you pack the products?

A3: In general, we use wood, plastic or carton boxes. We also put some soft materials inside to prevent possible damage on products.

Q4: How much advance payment do I need to make?

A4: If the products you buy are in stock, you need to make full payment; if the products are out of stock, you need to make about 50 percent of full payment and then we will start the production process. However, you still need to pay the rest of charges before we deliver the products.

Q5: What kinds of payment do you accept?

A5: In addition to the patterns of payment shown above, you can discuss with us about in which way you would like to pay.

Please contact us if you have any other questions:

Contacter: Sally

QQ: 3190671610

Tel/Fax: +86-0813-8263868

Mobile/WeChat/Skype/WhatsApp: +86 13714084219

A1: It depends on specific conditions. However, it could be 10 to 15 days on average.

Q2: Do you offer samples?

A2: Yes, we do offer samples. However, buyers need to pay for the freight charge. In addition, whether samples are free or not depends on the quantity you buy.

Q3: How do you pack the products?

A3: In general, we use wood, plastic or carton boxes. We also put some soft materials inside to prevent possible damage on products.

Q4: How much advance payment do I need to make?

A4: If the products you buy are in stock, you need to make full payment; if the products are out of stock, you need to make about 50 percent of full payment and then we will start the production process. However, you still need to pay the rest of charges before we deliver the products.

Q5: What kinds of payment do you accept?

A5: In addition to the patterns of payment shown above, you can discuss with us about in which way you would like to pay.

Please contact us if you have any other questions:

Contacter: Sally

QQ: 3190671610

Tel/Fax: +86-0813-8263868

Mobile/WeChat/Skype/WhatsApp: +86 13714084219

01

About Color Aberration

Product pictures are all physical photography, due to photo-taking technology, light, display parameters, etc., there may be

differences between the received physical objects and photos, please refer to the physical.

02 Cargo Receipt

All our products go through strict inspection and count before shipment. Please check the goods in person when they receive them.

Please refuse to sign and contact us if you find that the CTN number and model is wrong or the product is damaged in transit.

03 Note

In order to get a better cutting surface and extend the service life of the tool, please use the tool handle with high precision,

rigidity and dynamic balance.

Product pictures are all physical photography, due to photo-taking technology, light, display parameters, etc., there may be

differences between the received physical objects and photos, please refer to the physical.

02 Cargo Receipt

All our products go through strict inspection and count before shipment. Please check the goods in person when they receive them.

Please refuse to sign and contact us if you find that the CTN number and model is wrong or the product is damaged in transit.

03 Note

In order to get a better cutting surface and extend the service life of the tool, please use the tool handle with high precision,

rigidity and dynamic balance.

Hot Searches