1. Installation and commissioning issue:

We will send 1-2 technicians to assist with machine installation and commissioning,

customer pays for their tickets, hotel and diet, etc Customer need arrange

3-4 skilled worker and prepare insallation machinery and tools.

2. Warranty time:

12 months from date of commissioning completion.

3. Supply full English documents:

including foundation drawings, manual book, electric wiring diagram, electric manual book and maintenance book,etc.

Advantages:

1. Inspected by the Inspection Institution of Bureau Veritas Certification.

2. 100% QC inspection Before Shipment.

3. Customized, Meet your needs.

4. Good stability, Low failure rate (technical maturity, technical precipitation, skilled workers),Exquisite appearance (mature craft).

5. Large factories, Prompt delivery.

6. Strict quality inspection department.

7. Over 10 years' production experience.

8. Professional design team to serve you.

9. CE certificate assure you our qualit.

Key point :

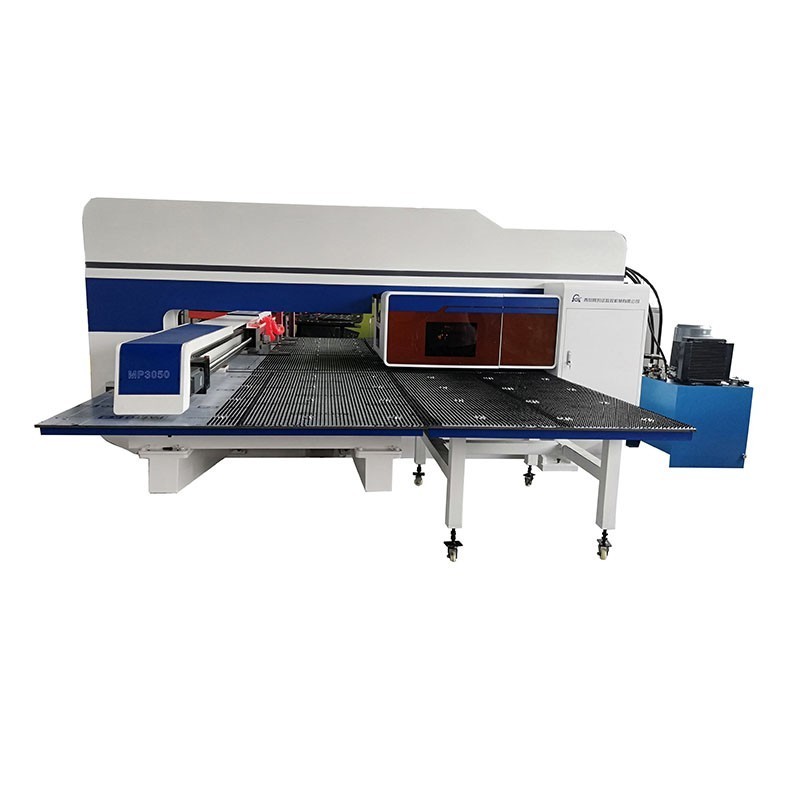

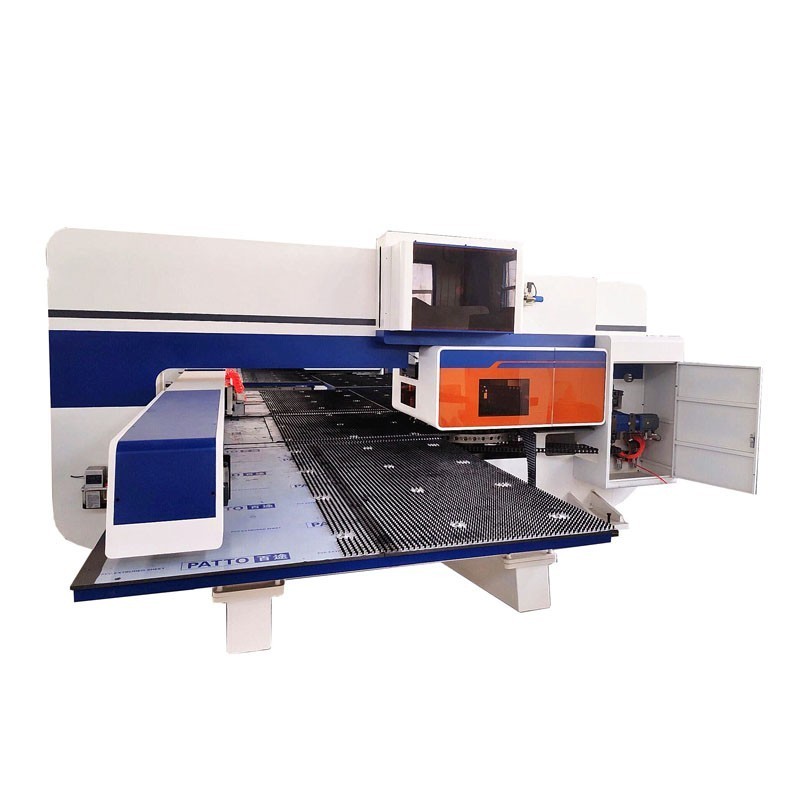

1. Production time: 25-30 days CNC punch machine.

2. Installation and commissioning time: 7-14 days.

3. Installation and commissioning issue: We will send 1,2 technicians to assist machine installation and commissioning, customer pays for their tickets, hotel and diet.

4. Warranty time:12 months from date of commissioning completion, but no more than 18 months from date of delivery.

5. Payment term: 30% as down payment, 70% balance before delivery or L/C at sight.

6. We supply full english documents, including general installation drawing, pit design drawing, manual book, electric wiring diagram, electric manual book and maintenance book, etc.

*Please contact us if you wish to know more details*