- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

WF

-

Dimension(L*W*H):

-

100T-8000T

-

Weight:

-

10 KG

-

Key Selling Points:

-

High quality with the most competitive price

-

Material::

-

Steel, Hot dip galvanized steel

-

Life time::

-

20 ~ 50 years

-

Quality certificates::

-

CE/ISO/BV

-

Usage:

-

Storage Grain

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Core Components:

-

silo

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

WF

-

Dimension(L*W*H):

-

100T-8000T

-

Weight:

-

10 KG

-

Key Selling Points:

-

High quality with the most competitive price

-

Material::

-

Steel, Hot dip galvanized steel

-

Life time::

-

20 ~ 50 years

-

Quality certificates::

-

CE/ISO/BV

-

Usage:

-

Storage Grain

-

After-sales Service Provided:

-

Field installation, commissioning and training

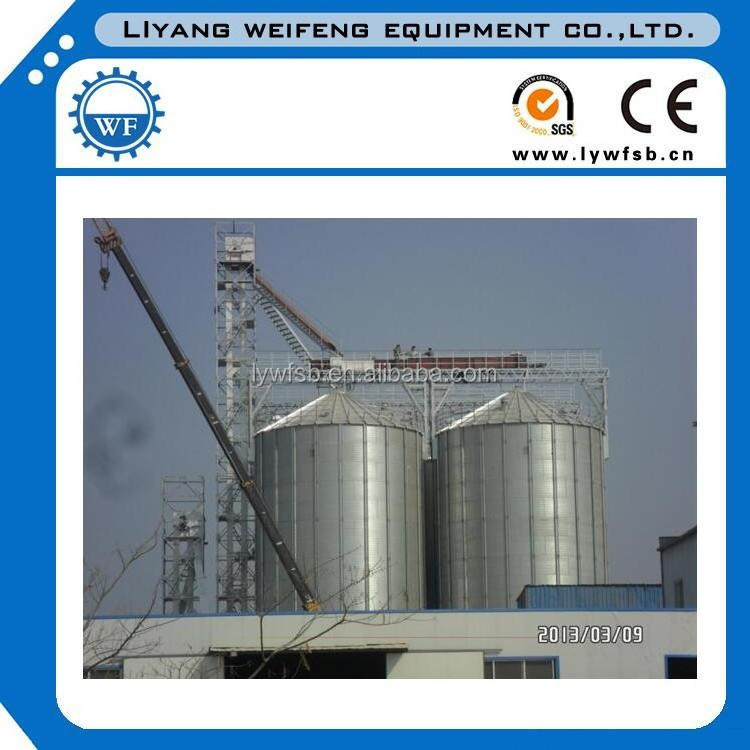

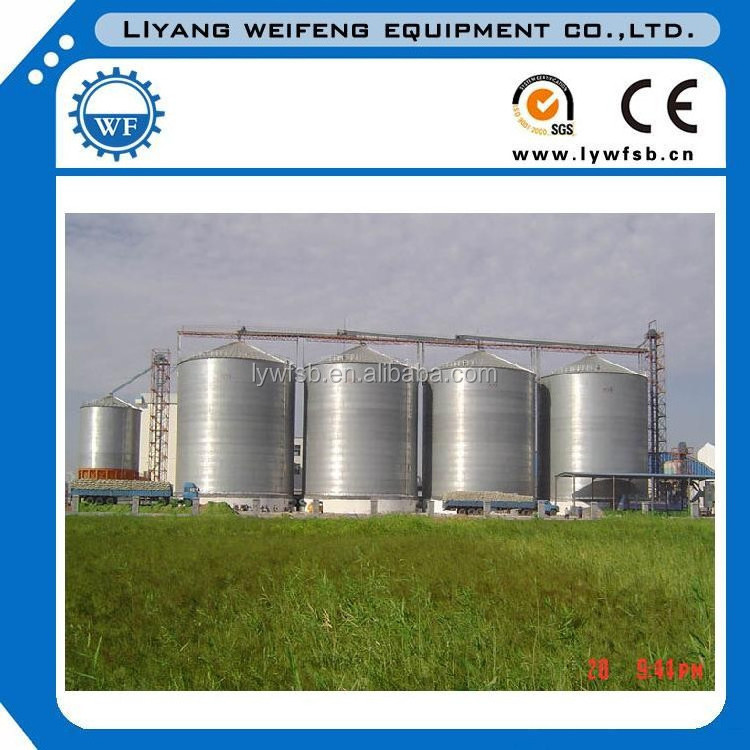

Liyang Weifeng Equipment Co., Ltd. is a professional manufacturer of ripple steel silo and its matching equipments. Equipped with advanced facilities, the complete production line of rolling and punching can be computerized. With its high accuracy and easy installation, the quality and reliability of the product have been improved.

How we assure the solidity of our Hot Sale Grain Steel Silo?

1. Roof Top:

The roof is design to stand up even the harshest environment of extreme snow disaster with each of top

and down part strong structure and connecting radial ribs which is Z interconnected again itself. Roof panels incorporate with ribs with over and under lap profiles ensuring a precise fit.

2. Body Steel Plate:

A commercial275g/m2 double galvanized steel coating increases life and durability.450g/m2 and 600g/m2 coating available for customized order.Each sidewall sheets are manufactured from high-tensile steel that has the ability to overcome extreme power, pressure.

3. Stiffeners:

SRON's high tension stiffener(can be located inside or outside silo) profiles make bins stronger allowing silos to stand well even under extreme hurricane. Base stiffener boots are coated so they won't rust over time.

4. Wind Ring:

For tall silos or that need to resist heavy wind. Wind ring and brackets reduce bolt holes in stiffeners; swaged technology ensure silo power load capacity.

5. High strength bolts and screws:

SRON's high strength bolts paired with sealing washers, coated hardware provides added protection from rust to ensure your grain bin stands the test of time.

6. Manhole:

double layer security locking manhole system.

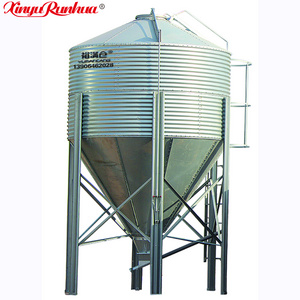

7. Wide Flange I-Beam Support Structure:

Wide flange I-Beam support structure has the strength and durability to support the heavy hopper silo loads long time, and with consideration of wind and seismic requirement.(Steel Silo Price)

Popular Model of Our Hot Sale Grain Steel Silo:

|

Most Popular Hopper Bottom Steel Silo Technical Specifications

|

||||||||

|

Capacity

|

50 ton

|

100 ton

|

150 ton

|

200 ton

|

300 ton

|

500 ton

|

1000 ton

|

1500 ton

|

|

Model

|

TCZK

|

TCZK

|

TCZK

|

TCZK

|

TCZK

|

TCZK

|

TCZK

|

TCZK

|

|

3605

|

4506

|

5506

|

5509

|

6410

|

7313

|

10013

|

12811

|

|

|

Diameter(m)

|

3.667

|

4.584

|

5.5

|

5.5

|

6.417

|

7.334

|

10.084

|

12.834

|

|

Total Height(m)

|

9.56

|

11.41

|

12.13

|

15.49

|

17.33

|

21.42

|

23.61

|

23.51

|

|

Volume(m3)

|

69

|

131

|

195

|

275

|

418

|

699

|

1379

|

2039

|

|

Density:

|

||||||||

|

0.75ton/m3

|

||||||||

|

Most Popular Flat Bottom Steel Silo Technical Specifications

|

||||||||

|

Capacity

|

1000ton

|

1500ton

|

2000ton

|

2500ton

|

3000ton

|

5000ton

|

8000ton

|

10000ton

|

|

Model

|

TCZK

|

TCZK

|

TCZK

|

TCZK

|

TCZK

|

TCZK

|

TCZK

|

TCZK

|

|

10014

|

10015

|

13715

|

14616

|

15518

|

18321

|

22921

|

26521

|

|

|

Diameter(m)

|

10.084

|

11.918

|

13.75

|

14.668

|

15.584

|

18.334

|

22.918

|

26.585

|

|

Total Height(m)

|

18.69

|

20.34

|

20.87

|

22.25

|

24.78

|

28.6

|

29.85

|

30.85

|

|

Volume(m3)

|

1335

|

2009

|

2701

|

3278

|

4145

|

6693

|

10640

|

14513

|

|

Density:

|

||||||||

|

0.75ton/m3

|

||||||||

Features of Our Hot Sale Grain Steel Silo:

1. High Accuray:

International advanced processing equipment and technology have been introduced to ensure the processing accuracy.

2. High Automation:

Steel silo makes high efficiency and labor saving possible with its high mechanization and automatin

3. Wide Manufacturing Range:

Wide range of manufacturing (with the capacity of 15000 tons for each silo) can meet the requirements of different clients with complete accessories and functions.

4. Easy Maintenance:

The standardized, serialized and generalized galvanized steel sheet and the accessories have been used to achieve the convenient maintenance, capacity increasing or moving.

5. Low Investment:

Compared with reinforced concrete silo, the total cost will be 30%-50% lower than that, which can largely reduce the cost.