- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yongxing

-

Dimension(L*W*H):

-

7.30*3.65*5.3m

-

Weight:

-

35

-

Product name:

-

Coal wood industrial steam boiler china

-

Application:

-

Industrial Production

-

Capacity:

-

2.8mw/h-14mw/h

-

Fuels:

-

Coal, Biomass pellet, Rice Husk, Bagasse, etc.

-

Stam temperature:

-

194

-

Warranty Period:

-

1 year

-

Heat efficient:

-

85%

-

Type of boiler:

-

Horizontal type boiler

-

Medium:

-

water

-

Application Field:

-

Papermaking Industry

Quick Details

-

Core Components:

-

FIRE TUBE

-

Steam Production:

-

2.8mw/h-14mw/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yongxing

-

Dimension(L*W*H):

-

7.30*3.65*5.3m

-

Weight:

-

35

-

Product name:

-

Coal wood industrial steam boiler china

-

Application:

-

Industrial Production

-

Capacity:

-

2.8mw/h-14mw/h

-

Fuels:

-

Coal, Biomass pellet, Rice Husk, Bagasse, etc.

-

Stam temperature:

-

194

-

Warranty Period:

-

1 year

-

Heat efficient:

-

85%

-

Type of boiler:

-

Horizontal type boiler

-

Medium:

-

water

-

Application Field:

-

Papermaking Industry

1. Agriculture: Breeding, greenhouse planting, seed factory.

2. Chemical industry: Fertilizer Plant, refinery, feed factory, coating factory, plastic factory, glass factory.

3. Manufacturing: Paper Mill, textile factory, food factory, shoe factory, ceramic factory furniture factory.

4. Construction Industry: Highway Use, site use.

5. Others: Accommodation and catering, bath cente, hotel, disinfection of medical instruments and clothing.

3. Manufacturing: Paper Mill, textile factory, food factory, shoe factory, ceramic factory furniture factory.

4. Construction Industry: Highway Use, site use.

5. Others: Accommodation and catering, bath cente, hotel, disinfection of medical instruments and clothing.

|

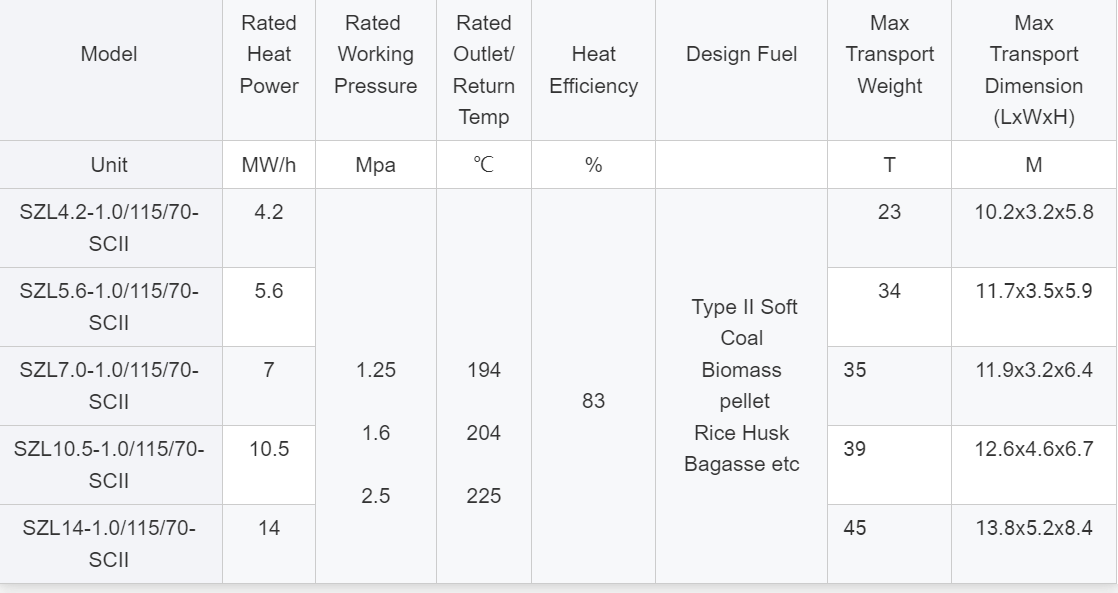

Model

|

Rated

Heat

Power

|

Rated

Working

Pressure

|

Rated

Outlet/

Return

Temp |

Heat

Efficiency

|

Design Fuel

|

Max Transport

Weight

|

Max Transport

Dimension

(LxWxH)

|

|

Unit

|

MW/h

|

Mpa

|

℃

|

%

|

|

T

|

M

|

|

SZL4.2-1.0/115/70-SCII

|

4.2

|

1.25

1.6

2.5

|

194

204

225

|

83

|

Type II Soft Coal

Biomass

pellet

Rice Husk

Bagasse etc

|

23

|

10.2x3.2x5.8

|

|

SZL5.6-1.0/115/70-SCII

|

5.6

|

|

|

|

|

34

|

11.7x3.5x5.9

|

|

SZL7.0-1.0/115/70-SCII

|

7

|

|

|

|

|

35

|

11.9x3.2x6.4

|

|

SZL10.5-1.0/115/70-SCII

|

10.5

|

|

|

|

|

39

|

12.6x4.6x6.7

|

|

SZL14-1.0/115/70-SCII

|

14

|

|

|

|

|

45

|

13.8x5.2x8.4

|

|

SZL20-1.25-SCII

|

20

|

|

|

|

|

38

|

11000x3300x3500

|

|

Name

|

Water tube double drums coal/biomass fired 4t/h-20t/h steam boiler

|

|

Pressure

|

0.7Mpa-2.5Mpa

|

|

Fuel

|

Coal, Biomass pellet, Rice Husk, Bagasse, etc.

|

|

Capacity

|

2.8mw/h-14mw/h

|

Description:

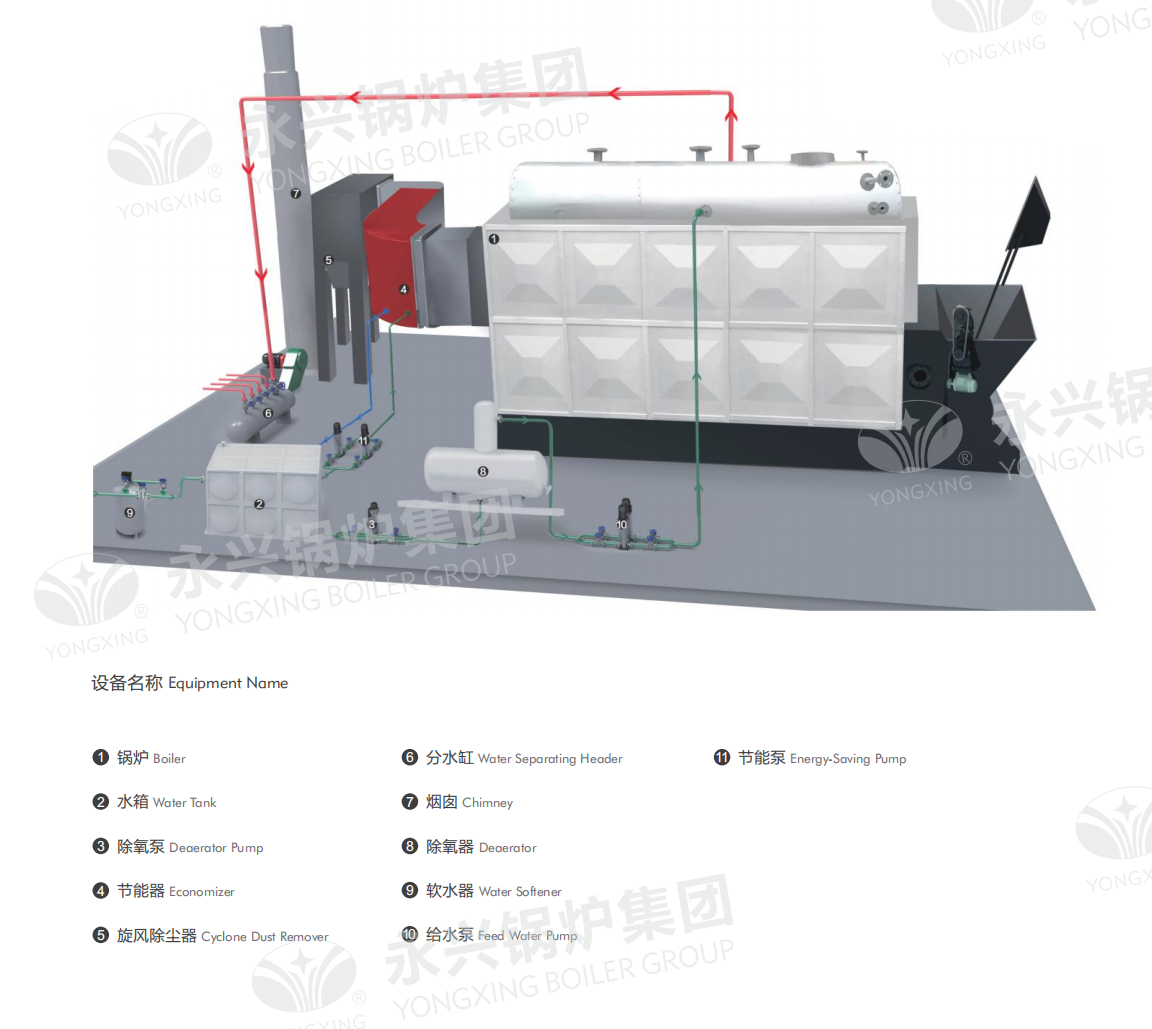

SZL type biomass boiler adopts double-drum vertical arrangement with chain grate, and the fuel is clean energy biomass (Cannot produce waste gas and waste smoke under combustion with low cost and easily obtain features, all to realize waste recycling), it meets market trends and customer request.

The boiler consists of two parts: the upper body boiler and the lower combustion part. The fuel is burned in the combustion chamber, and the generated flue gas which enters the tail flue through furnace, combustion chamber, convection tube bundle, etc, and then discharge to the air by dust remover, induced draft fan and chimney.

The two sides on the chamber of SZL biomass boiler adopts membrane all wall structure, which not only improves the sealing performance of boiler, but also increases the volume and the heating surface. What is better is that the front and rear walls are arranged with secondary air (controlled by the valve), which not makes fully combustion of fuel, but also improves the combustion and thermal efficiency, reducing the fuel cost and waste generation. What's even better is that it also has the advantages of high automation, safe and stable operation, perfect protection function, etc. It has became an ideal choice for many enterprises who plan to purchase boiler.

Membrane Wall Structure

The body boiler uses membrane water wall structure, good sealing and low heat lose.

Horizontal Type Three Passes Structure

Adopts horizontal type three passes structure and large furnace, ensure the sufficient combustion, and absorb the thermal

expansion effectively

expansion effectively

Chain grate and

Reciprocating grate

Reciprocating grate

The boiler could be equipped with chain grate and reciprocating grate based on the fuel characteristics, has high combustion

efficiency

efficiency

2tph steam boiler in UZ

4tph diesle steam boiler in Kenya

25tph steam boiler in Myanmar

Vertical coal fired steam boiler in Chile

3mkcalph coal fired thermal oil boiler in Vietnam

2tph biomass boiler in Togo

1200kw diesel fired thermal oil boiler in Zimbabwe

2tph coal steam boiler in Philippines

10tph steam boiler in Ukraine

25tph coal fired steam boiler in Bangladesh

Electrical steam boiler in Ethiopia

2x12m wood treatment equipment in Zambia

Q1: What are the spare parts for DZL/SZL series coal/biomass fired boiler?

Generally, the spare parts are instrumentation valve, grate plate, gasket, etc.

Q2: What are the difference between DZL and SZL with the same capacity?

DZL

1. Usually for the boiler with capacity lower than 10Ton

DZL

1. Usually for the boiler with capacity lower than 10Ton

2. Easy for transportation

3. Lower request on water quality

4. Low boiler room construction charges

5. Low requirement on water quality

SZL

SZL

1. Usually suitable for bigger capacity boiler

2. Good water circulation, small water volume

3. Warm up faster, higher steam quality

4. Higher request on water quality

5. Higher thermal efficiency

Q3: What are the differences between vertical type boiler and horizontal type boiler with the same capacity?

1. Structure of vertical boiler is compact, occupy a limited area.

Q3: What are the differences between vertical type boiler and horizontal type boiler with the same capacity?

1. Structure of vertical boiler is compact, occupy a limited area.

2. Convenient on installation and removal.

3. Low cost and investment on capital construction. Steam exhausted fast and sufficient.

Q4: What are the limitation (size, humidity, chemical element concentrations) of coal fuel/solid fuel/wood fuel?

Size requirement of coal:6-25mm Size requirement of blending coal: <50mm (the coal less than 6mm should less than 30%) Diameter of biomass particle: 6~10mm, length: 25~50mm, water content < 15%, ash content < 2%, sulphur content<0.07%, chlorinity <0.07%, nitrogen content < 0.5%

Q5: What is the size of furnace door and blower hopper?

Q4: What are the limitation (size, humidity, chemical element concentrations) of coal fuel/solid fuel/wood fuel?

Size requirement of coal:6-25mm Size requirement of blending coal: <50mm (the coal less than 6mm should less than 30%) Diameter of biomass particle: 6~10mm, length: 25~50mm, water content < 15%, ash content < 2%, sulphur content<0.07%, chlorinity <0.07%, nitrogen content < 0.5%

Q5: What is the size of furnace door and blower hopper?

Size of furnace door: Standard elliptical furnace door:300*800*1500 Blower

hopper size: 2 tons conical hopper: 1400*800*1500 4 tons conical hopper: 2200*1400*1500

Q6: What is the combustion mode of coal/biomass fired boiler?

hopper size: 2 tons conical hopper: 1400*800*1500 4 tons conical hopper: 2200*1400*1500

Q6: What is the combustion mode of coal/biomass fired boiler?

The combustion mode of coal/biomass fired boiler is layer combustion. Place the flue on the fixed or moved grate, to form an evenly fuel bed with a certain thickness, air comes from the bottom of grate, and combustion occurred on the fuel bed.

Q7: What is the thickness of refractory?

The thickness of refractory: 50-60mm

Q8. What is the installation sequence?

Boiler- Economizer- Dust collector - ID fan - chimney

Hot Searches