- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ChiKin

-

Weight (KG):

-

2780 KG

-

Name:

-

CNC PCB printed circuit board drilling cutting machine machinery

-

Type:

-

PCB DRILLING MACHINE

-

Lathe Material:

-

Granite

-

Spindle Material:

-

Aviation Aluminum

-

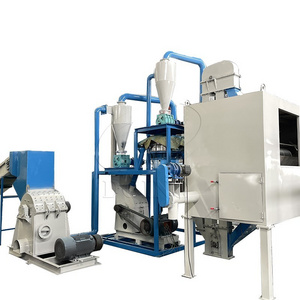

Crumbs suction:

-

Automatic

-

Drive system:

-

Panasonic Servo Motor

-

Tool magazine capacity:

-

200PCS

-

Precision:

-

±0.005mm

-

Usage:

-

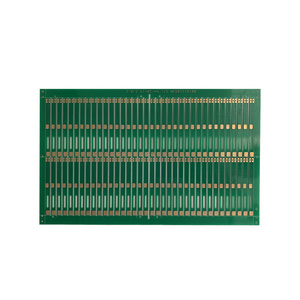

Aluminum, Copper PCB, Acylic, FR4, FR2, XPC Phenolic board etc

-

Application:

-

PCB, LED, LCD Display, Electronic ICT

Quick Details

-

type:

-

Bench Drilling Machine

-

Max. Drilling Dia. (mm):

-

6.35mm

-

Range of Spindle Speed(r.p.m):

-

160000 - 200000 r.p.m

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ChiKin

-

Weight (KG):

-

2780 KG

-

Name:

-

CNC PCB printed circuit board drilling cutting machine machinery

-

Type:

-

PCB DRILLING MACHINE

-

Lathe Material:

-

Granite

-

Spindle Material:

-

Aviation Aluminum

-

Crumbs suction:

-

Automatic

-

Drive system:

-

Panasonic Servo Motor

-

Tool magazine capacity:

-

200PCS

-

Precision:

-

±0.005mm

-

Usage:

-

Aluminum, Copper PCB, Acylic, FR4, FR2, XPC Phenolic board etc

-

Application:

-

PCB, LED, LCD Display, Electronic ICT

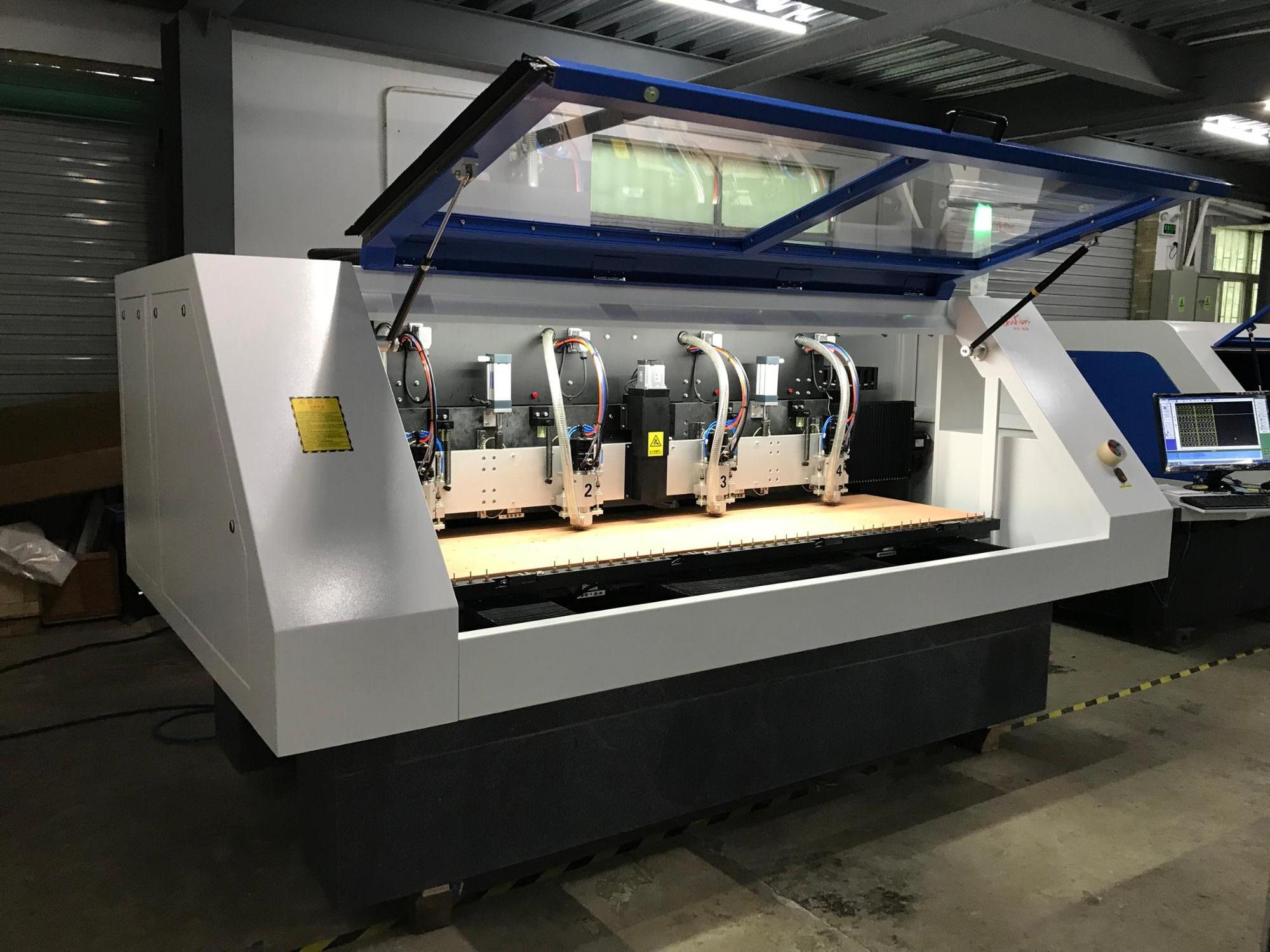

PCB Drill Spindle ATC 200000 rpm Motor PCB Drill For PCB Making Line

| PCB Drill Spindle ATC 200000 rpm Motor PCB Drill For PCB Making Line | |

| Model | CK-04D |

| Spindle | 4 |

| Spindle Specification |

High Speed Air Bearing Spindle (200000 rpm) |

| Drive System | Panasonic Servo Motor |

| X.Y.Z rail and ballscrew | Japan NSK |

| Moving Speed | 40m/min |

| Table Dimension | 560mm x 680mm |

| Tool Change | Automatic Tool Change |

| Tool Detection | Included ( Diameter, Lenght and Broken Detection) |

| Repeat Accuracy | + / - 0.005mm |

| Positioning Accuracy | + / - 0.005mm |

| Drill Bit Size | Φ0.2mm - 6.0mm |

| Power | AC 380V 3PH 10KVA |

| Air Supply | 0.6 - 0.8 Mpa |

| Machine Size | 2100mm x 1850mm x 1700mm |

| Machine Weight | 2400KG |

| Machine Controller System | Self-Develop Drill System, Also can be updated to Sieb & Meyer System |

CNC PCB DRILLING MACHINE

This drilling machine is computer-controlled. The operator selects the right drill program. This tells the machine which drill to use and the X Y co-ordinates of the holes. Our drills use air-driven spindles which can rotate up to 200,000 revolutions per minute. High speed drilling ensures clean hole walls to provide a secure base for good plating on the hole walls.

Drilling is a slow process as each hole must be drilled individually. So depending on the drill size we drill a stack of one to three PCB panels together. We can drill holes down to 150 microns in diameter. To give you an idea of the size, the diameter of a human hair is about 150 microns. Drill change is fully automatic. The machine selects the drill to use from the drill rack, checks that it is the correct size, and then loads it into the drill head.

Once all the holes are drilled the operator unloads the panels from the drilling machine and discards the entry and exit material.

Q: How many layers does this machine can process?

A: This machine can process single-sided pcb, double-sided pcb and multi-layer pcb.

Q: What kind of program format can this machine identify?

A: This machine can identify EXCELLON format, Gerber format and NC format.

Q: Is there only 2 spindle machine?

A: Our standard is 2 spindle and 4 spindle machine, also can custom single spindle, 3 spindle machine in accordance with customer requirement.

Q: What is the warranty of this machine?

A: 1 year from the date of machine installation in customer place.

Q: What is the traning way of machine operation?

A: There are 2 options for customer as below

Option 1: Customer pre- buy off the machine and finish the traning in our factory, and we will bare the fee of accomodation for customer's engineer (1-2 person)

Option 2 : Our engineers available to service machinery oversea in customer place, with bare the fee of accomodation by customer side.