- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 400*150*200 mm, 240*115*90 mm

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa AAC bricks/panels making machine

-

Voltage:

-

220V OR 380V

-

Dimension(L*W*H):

-

1350*1460*1800mm

-

Weight (KG):

-

500000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

aac aerated concrete block plant

-

Raw material:

-

Fly Ash or sand

-

Weight/M3:

-

500kgs/m3-700kgs/m3

-

Power:

-

170KW

-

other name:

-

50000 aac plant

-

Product Name:

-

AAC bricks AAC panels making machine of aac plates

Quick Details

-

Type:

-

Autoclaved aerated concrete block (AAC), light weight block, hebel bricks machine

-

Brick Raw Material:

-

fly ash or sand

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 4000-60000 Pieces/day

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 400*150*200 mm, 240*115*90 mm

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa AAC bricks/panels making machine

-

Voltage:

-

220V OR 380V

-

Dimension(L*W*H):

-

1350*1460*1800mm

-

Weight (KG):

-

500000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

aac aerated concrete block plant

-

Raw material:

-

Fly Ash or sand

-

Weight/M3:

-

500kgs/m3-700kgs/m3

-

Power:

-

170KW

-

other name:

-

50000 aac plant

-

Product Name:

-

AAC bricks AAC panels making machine of aac plates

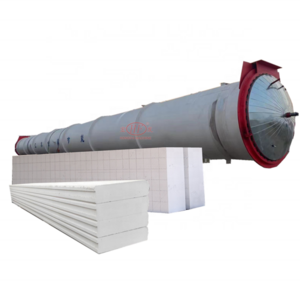

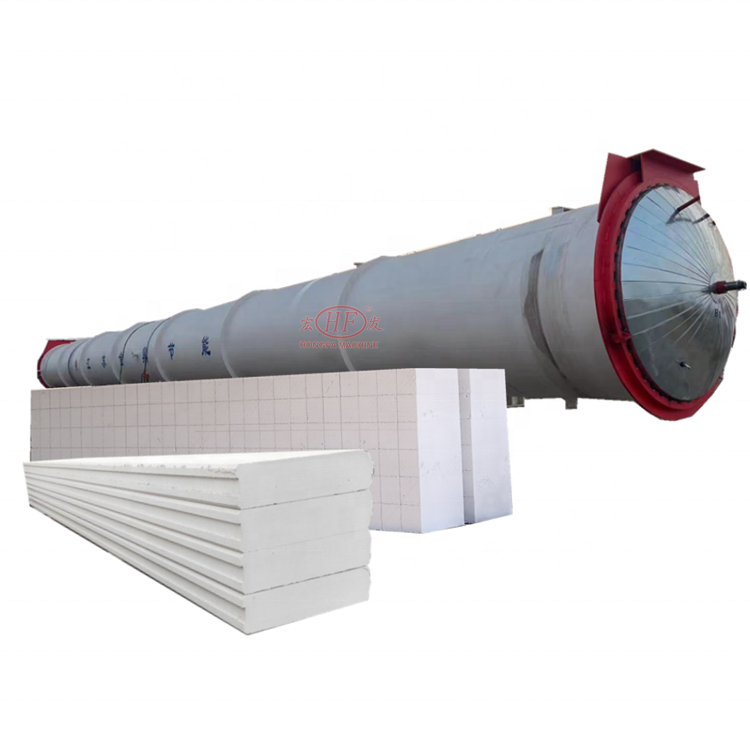

AAC autoclave concrete aerated blocks concrete block machine plant

Autoclave / Autoclave For Aac Blocks / Autoclave For Block Making Product

Hongfa Grounp provides worldwide customers with comprehensive technical solutions for the production of autoclaved aerated concrete (AAC). Nowadays, autoclaved aerated concrete blocks and panels are widely used in exterior walls, interior partitions, floors and roofs of various structures, and prefabricated steel buildings.

The entire production line is highly intelligent and environmentally controlled, it is a modern, high-quality autoclaved aerated concrete production plant.

Basing on the development concept of green, low-carbon, and intelligentization, we support autoclaved aerated concrete plant solution provides entire lifecycle services for worldwide customers to ensure efficient and high-quality production of AAC products.

Brief introduction

Areated concrete brick (light brick ) is the light and porous buidling material. It has light weight keeping temperature cant burn and other advantages.it can be made into many kinds of bricks(for example:600×200×100,80×80×180,240×115×53,600×200×125),they could be used industry building and common building.they are more and more popular in the world.in the future,they will replace the Clay brick completely.

Advantages

light weight

Areated concrete density is usually 400-700kg/m3,(according the market in produce ),same as 1/3 of clay brick and 1/5 common concrete.So use the Light brick can reduce the weight of the build more,and also reduce the beam of roof and pillar press best.then you can see,it can save the material and cost,it also fighting shaking.

keeping temperature

aerated concrete panel has many porous,the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or 1/5 of clay brick,so it is best materials now in the world. Also many kinds raw material,have lowest wasteMain Material:coal ash sand waste mine material coal stone,stone dust and other silicon materials.

aac block manufacturers

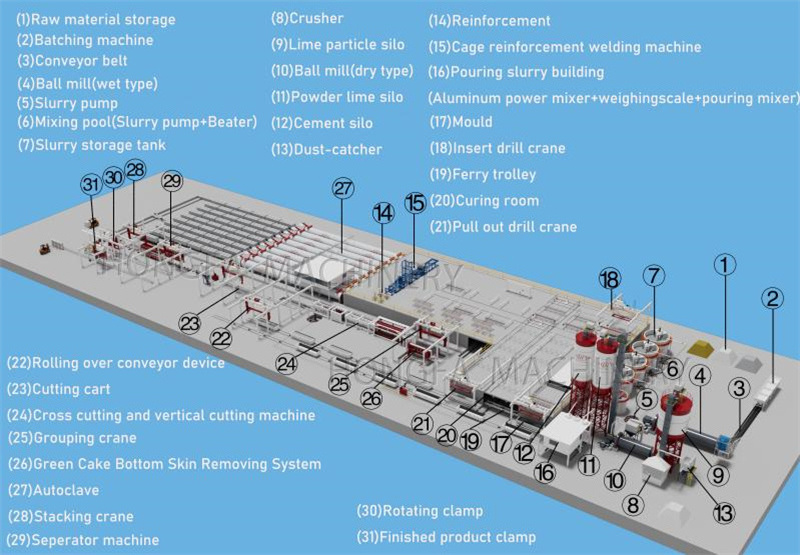

Hongfa AAC block production line supply complete solution of the whole section operating needed equipment

1.Raw material preparation for AAC plant:

A, Milling sand ( fly ash no need mill) and to make slurry

B, Lime: crushing - milling ( or to buy lime power directly)

C, Gypsum:to mill with sand or lime or input with fly ash then to make slurry directly.

1. Dry and wet Ball mill for lime and sand

3.Slurry batching: The prepared and stored raw materials to be used are metered, adjusted for temperature and concentration, and a small amount of dosing materials are metered on-site, and then fed to the stirring equipment in turn according to the process requirements.

4. Pouring: In this process, the materials that are put into the mixer after the previous batching process are measured and adjusted if necessary, and the materials that meet the time, temperature, and consistency requirements of the process are made, then pouring into the mold. The pouring process is an important process that can form a good pore structure, and it constitutes the core link of aerated production as the batching process.

5. Cutting: As the main equipment in the production process of aerated concrete block, the quality and cutting accuracy of aerated block cutting machine directly affect the quality of AAC block. JQF series of air filling block cutting machine of our company has the characteristics of high efficiency and high degree of automation.

1) Highly intelligent operation and management, PLC centralized control, with frequency converter to realize the whole cutting process automatic operation.

2) Hongfa cutting machine can not only produce AAC blocks, but also produce ALC panel, and cut the blocks and panels in six sides, so the quality of products is not affected by mould oil and mould deformation.

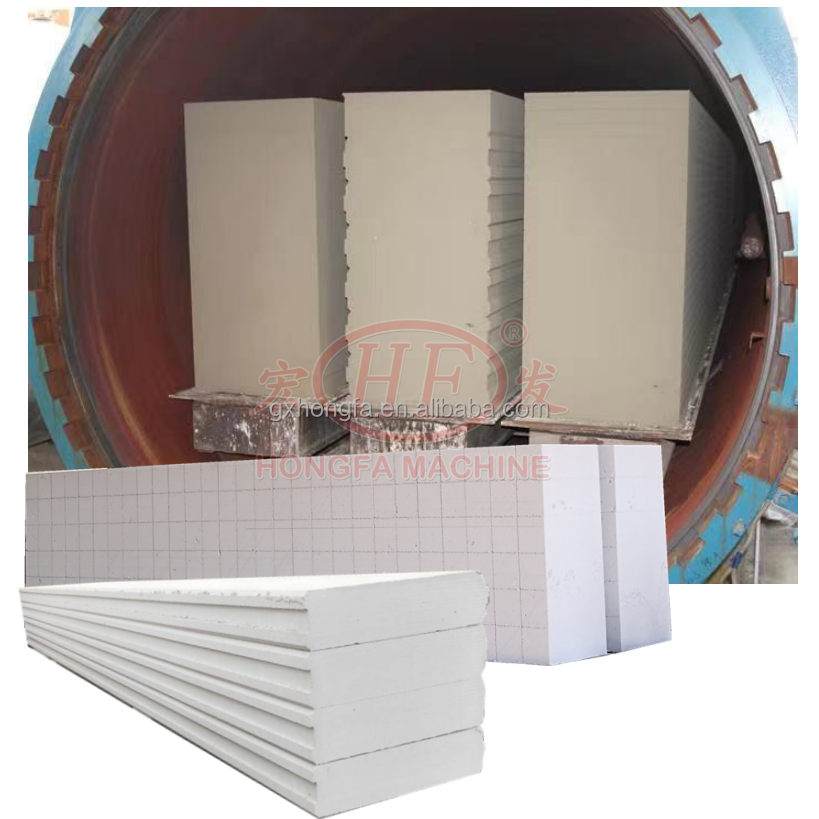

6.Autoclave curing for AAC block:

The selection of several commonly used autoclaves and the requirements of annual output and quantity of AAC block production line in the form of table as follows:

|

Specification and model (m) |

mold specification |

annual production scale ( m3) |

|

Φ2.0×31 |

4.2*1.2*0.6 |

100,000-200,000 |

|

Φ2.68×31 |

4.8*1.5*0.6 |

150,000-300,000 |

|

Φ2.68x32 |

6*1.2*0.6 |

20 0,000-350,000 |

7. Out off Autoclave for Hongfa Aerated Concrete Material and AAC Block (ALC) wall panel Type AAC panel making machine: Including finished AAC blocks out of the autoclave, lifting, separation, inspection, packaging and cleaning and oiling of trolleys and bottom plates.

8. Main Equipments of Hongfa Aerated Concrete Material and AAC Block (ALC) wall panel Type AAC panel making machine: AAC Block seperater

aerated concrete panel programme

1, Technological Standard

The technological standard of this project is superior products according to the Chinese national standards. The equipments are made according to Chinese standard and criterion

This project provides the mature tilting technology in China.

2, Capacity

The product is AAC blocks with the capacity of 30,000m3- 3 00,000m3 /year

3. Product specification

The products reach the block requirements of grade 04~07 of GB11968-2006

Main Material

coal ash sand waste mine material coal stonestone dust and other silicon materials.

1. Product weight is according to 600kg/m3 to control.

2 .annual capacity 200,000M3.

3. set raw material proportion: cement 6.5%, raw lime 23%, flyash 68%, gypsum 3%, aluminum paste powder 350g/M3.

4. water and material rate 0.631

5. one mould product 2.88M3

6. Casting slurry cycle time 5-6 minutes, cut cycle time 5 minutes.

7.casting slurry temperature 38-42 degree

8 .body quiet stop. Time is 1.5-2.5housr, temperature 50-90 degree, after quiet stop body strength is 0.15-0.18Mpa

9 .Steam curing cycle time, come in and out autoclave about 0.5hour, steam curing cycle time about is 6 hours/1.6Mpa, total 6.5 hours

AAC used

Packing: Naked packing or stretch film packing or according to customers' requirements

Delivery time: Within 30 days after receipt of deposit and moulds confirmation from buyer

1.Guarantee for one year and after sale service for whole life.To offer free design,free technology support and free machine maintenance trainning.

2.We will provide you with a set of spare parts for free!